Manufacturers: Henry Simon Ltd

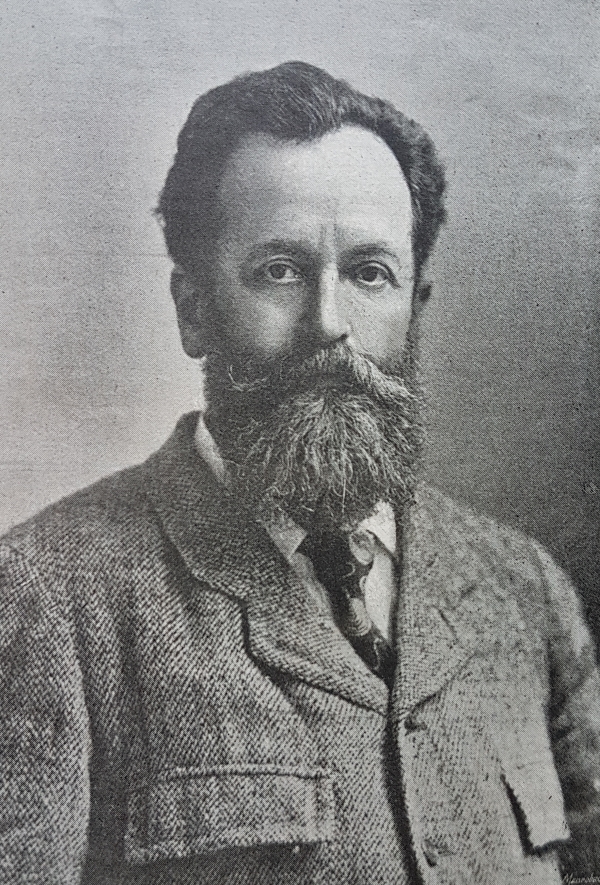

Gustav Heinrich Victor Amandus Simon (known as Henry Simon) came to Britain in 1860, by 1867 he had set himself up as a consulting engineer and, just over ten years later, installed ‘the first complete roller-mill plant’ (Simon, 1953, p.11). This was the beginning of the firm Henry Simon Ltd. which would become one of the leading suppliers of roller machinery throughout the world.

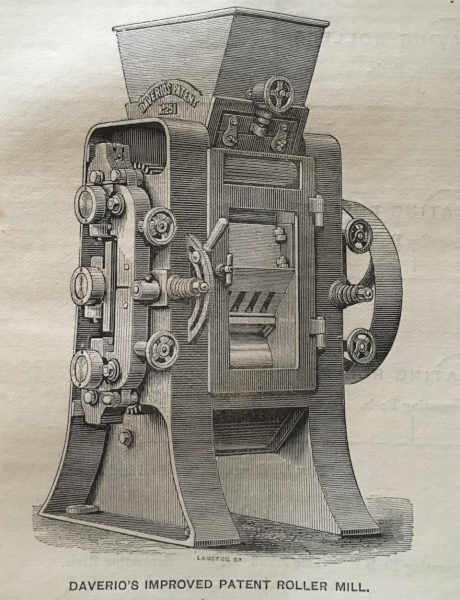

The beginnings of Henry Simon Ltd. can be dated to the 1878 installations for the McDougall Brothers in Manchester. This installation was the first ‘complete roller mill facility integrating the gradual reduction system’, as opposed to just installing rollers in place of stones (Acklin). The installation was made possible through a partnership between Henry Simon and Gustav Daverio. Daverio’s machinery was employed ‘almost exclusively’ by Simon during his early years and was installed into the mills Simon designed, an arrangement that benefitted both men (Simon, 1882, p.203).

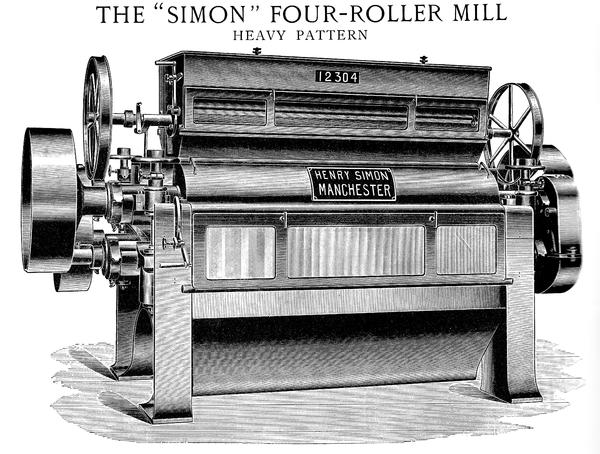

The decade following this installation for the McDougall Brothers saw Henry Simon rely more on his own designs and the ‘Daverio’ System was phased out as the Simon System replaced it. From 1883 to 1885, Simon advertised his own two-roller mill, three-roller mill and four-roller mill, which were then installed into mills throughout Britain. However, the majority of the machinery was not actually made in Britain, or by Simon, as he did not have the facilities to do so. Instead, an arrangement was made with Adolf Bühler in Uzwil, Switzerland, who made the machinery following Simon’s designs. This partnership was crucial for Simon as it ‘is unimaginable that Henry Simon could have achieved the speed of effective performance, which British millers needed if he had been fully responsible also for machine manufacture’ (Jones, p.196).

This partnership with Bühler helped Simon establish a business overseas, particularly on mainland Europe. To aid with this trade, another partnership was established in 1892 when a new plant was opened in Frankfurt, under the name Simon, Bühler & Baumann. This firm was very successful and was ‘one of the three or four leading milling engineering firms in Germany until its confiscation during the first World War’ (Simon, 1953, p. 12). However, this establishment was the result, rather than cause, of Simon’s overseas success as by the time it was founded, Simon had already installed over 400 mills worldwide. One country pivotal to this overseas success was Australia. James Radford had been installed there as an agent for Simon machinery from 1887 to 1890 and was responsible for many installations. Indeed, the Australian and New Zealand markets proved so important that Henry Simon established a new branch in Sydney in 1893 in order to fulfil demand: Henry Simon (Australia) Ltd.

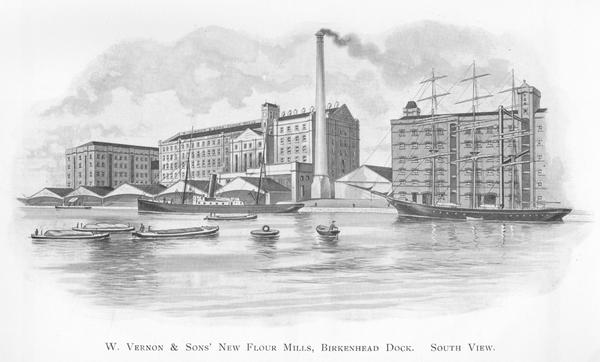

Therefore, by the end of the 19th century, Henry Simon Ltd. was a flourishing company. Their success culminated in the building of W. Vernon & Son’s two 30 sacks per hour plants at Birkenhead in 1899. However, the new century would bring new challenges and no founder to lead them as Henry Simon died in July 1899. Leadership of the company then passed to Joseph Ingleby, Simon’s ‘chief help’ who became chairman, and George Huxley, the head of the drawing office who became managing director (Jones, p.182).

Henry Simon Ltd. started the 20th century as it had finished the 19th, successful and eager to expand. In 1902 its first factory was opened at the Eagle Iron Works, Stalybridge, but the arrangement with the newly formed Bühler Bros. still existed and they still manufactured Simon machinery. This machinery was needed as by 1904 the company was ‘unprecedently busy’ with twenty complete roller plants in the course of erection, along with other alterations and improvements (Jones, p.233-4).

Ten years after this exceptionally busy year, the world was at war. The First World War caused disruption for the business as the factory at Stalybridge, and the one acquired at Bredbury in 1915, stopped producing machinery and instead made munitions. The conclusion of the war four years later meant that the company could return to producing milling machinery. However, a new difficulty now presented itself. Conditions in Europe were such that ‘Continental milling engineers…almost monopolised the European markets’ (Simon, 1953, p.15). Wages were so low that firms on the Continent could sell machinery at almost half British prices. This caused difficulties for Henry Simon Ltd. and they arranged to have machinery made in France to combat the situation. This arrangement, along with new clients in China and Japan and the maintenance of their ‘technical milling’ expertise, saw the company survive this initial post-war crisis.

The remaining inter-war period saw two major advancements for Henry Simon Ltd. The first was the building of a new engineering works site at Cheadle Heath, Cheshire. These works were opened in 1926 and by 1930 the entirety of the staff had moved there. On this site the ‘whole of the specialised products of…Henry Simon Ltd., are manufactured’ (Henry Simon 1935 Review). These specialised products now included provender milling equipment as well. Given that many flour millers were also provender millers, Henry Simon Ltd. decided to supply this machinery as well and were the only firm capable of ‘designing, equipping and starting up a complete provender plant’ (Simon, 1953, p.20).

The events of 1939 again caused an interruption in the running of Henry Simon Ltd. as the Second World War started. Again, the factories ceased producing milling machinery and instead produced armaments for the war. However, at the conclusion of the Second World War, Henry Simon Ltd. enjoyed better fortune than it had at the end of the First World War. Rather than facing tough opposition from the Continent, especially from Germany, in the production of machinery, there was instead a vacuum as ‘the formidable competition of Germany was eliminated’ (Simon, 1953, p.16). The mills throughout the world that were ‘obsolete, damaged or destroyed’ were all potential clients (Simon, 1953, p.16). The company acted quickly to return to normal production and installed agents in foreign countries to promote the company and gain new business. Within a year of the war ending, Henry Simon Ltd. had orders for ‘more than forty new mills and machinery…to nearly forty countries’ including the previously ‘unpenetrated dollar markets of the United States and Canada’ (Simon, 1953, p.16).

Henry Simon Ltd. therefore enjoyed success during the late 1940s and early 1950s. The rest of the 20th century was marked by the number of mergers and acquisitions that took place involving Henry Simon Ltd. The first took place in 1960 when the two Simon Engineering Companies, Henry Simon (Holdings) Ltd. and Simon-Carves Ltd., merged to form Simon Engineering Ltd. Then in 1988, the two great British companies, Henry Simon and Thomas Robinson and Son, merged to become Robinson Milling Systems Ltd. This business was then acquired by the Satake Corporation in 1991 to form Satake Robinson UK Ltd., then renamed to Satake UK Ltd. Today, Henry Simon is still owned by Satake and in 2017, Satake announced that in partnership with Alapala, the Henry Simon brand of machinery was being reintroduced and is now available for purchase.

Read more about the founder, Henry Simon, here.

Sources:

‘Henry Simon: 1935 Review’, 1935 Iron and Steel Institute, https://www.gracesguide.co.uk/Henry_Simon:1935_Review accessed on 12.01.18.

Acklin, Teresa, ‘Remembering a pioneer in flour milling’, World-Grain.com (November 1, 1999) accessed on 12.01.18. http://www.world-grain.com/News/Archive/Remembering-a-pioneer-in-flour-milling.aspx

Simon, Anthony, The Simon Engineering Group (Stockport, 1953).

Simon, Henry, ‘Modern Flour Milling in England’, Proceedings of the Institution of Civil Engineers (1882).

Simon, Henry, The Present Position of Roller Flour Milling (Manchester, 1892).