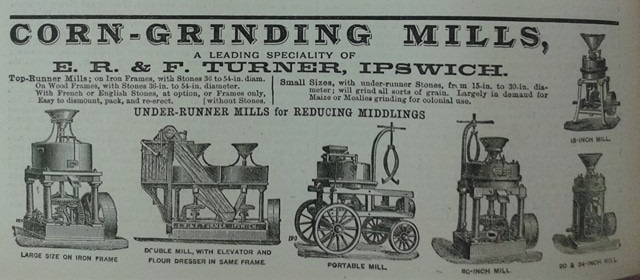

Manufacturers: E. R. & F. Turner

The engineering firm that would become E. R. & F. Turner started life in July 1837 when Walton Turner and his two partners, Henry Cooper Bond and George Hurwood, established an iron founders and general engineering works in Ipswich. The Bond, Turner, and Hurwood partnership lasted ten years until Walton Turner died and his son, Edward Rush Turner, replaced his father. The company then became known as Edward Turner, Rush and Co. until Mr. Hurwood retired in 1851. Edward Rush Turner then went into partnership with his brother, Frederick, and the firm E. R. & F. Turner was born.

During these early years the firm focused on designing and making steam engines. Indeed, at the 1851 Great Exhibition, Edward Rush displayed a four-horse power portable steam engine, along with a steam-boiler feeding apparatus and a crushing mill. The machinery was all of good quality with the portable steam engine described as ‘cutting edge technology’ (Filby, p.48). The display at the Great Exhibition helped ‘put Turner’s on the world stage and helped them attract a world-wide reputation as esteemed engine builders and boiler makers’ (Filby, p.48).

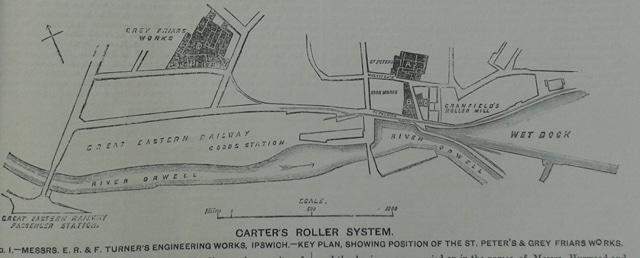

Despite this world-wide reputation, the firm found that their premises at St. Peter’s Works were sufficient for business, manufacturing steam engines and crushing mills, until the 1880’s. At this point the firm began to expand, as reflected by the number of employees. In 1861 the Turner’s employed 110 men and 30 boys whilst in 1871, they employed around 160 men and 33 boys. A limited growth had then taken place in these ten years. However, between 1871 and 1881, a much bigger growth took place with 237 men and boys then hired by the firm. This growth reflected an expansion in their trade and caused the firm to move to a new and bigger premise, Grey Friars Works.

The growth, already alluded to, that took place in this manufacturing business was an interest in the wider milling industry. Whilst they already made crushing mills, and their steam engines were often used to power millstones, they now started to produce roller mills too. Their first manufacturing experience was actually one of the first to take place in Britain. In 1862 they installed a new plant for Mr. Joseph Fison of Ipswich, based on the design by Mr. G. A. Buchholz. This design included a ‘pair of rolls for a first break’, which ‘were of steel, 9 inches in diameter, grooved helically both right- and left-handed, with a pitch of about 15 inches’ (Jones, p.41; Forrest, p.240). E. R. & F. Turner manufactured this machinery, under Buchholz’s direction, which was believed to be the first of their kind in Britain.

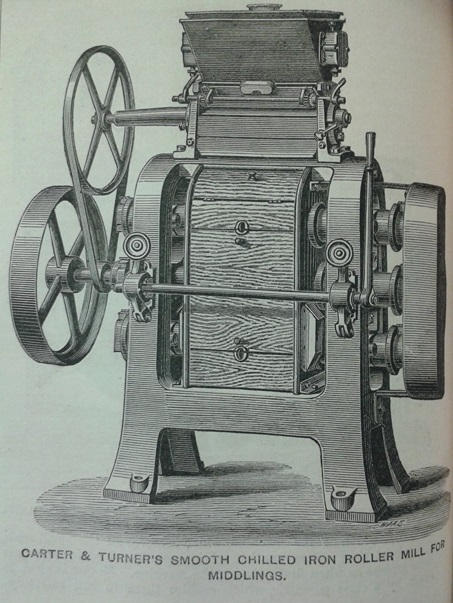

During the 1870’s, most of the roller milling expertise could be found on mainland Europe. As such, a milling expert, Mr. J. Harrison Carter, and Pierson Turner, a partner of E. R. & F. Turner, travelled to Hungary to investigate these mills and machinery. On their return, a partnership was formed between E. R. & F. Turner and Harrison Carter and in a few years, Turners could produce a complete roller mill plant on the Harrison Carter system. When Mr. Carter retired for the first time, in 1888, E. R. & F. Turner took over his business. So it could be said that ‘By 1888 ER & F Turner were designing and producing their own roller mills’, which were then frequently powered by their ‘John Bull’ steam engines (Filby, p.48).

One year after they could claim to be designing and producing their own roller mills, the firm was turned into a Private Limited Company. They took the title of E. R. & F. Turner, Limited, with Edward Rush Turner, Frederick Turner, Peirson Turner, Leonard Turner, and Frederick William Turner serving as Directors of the firm.

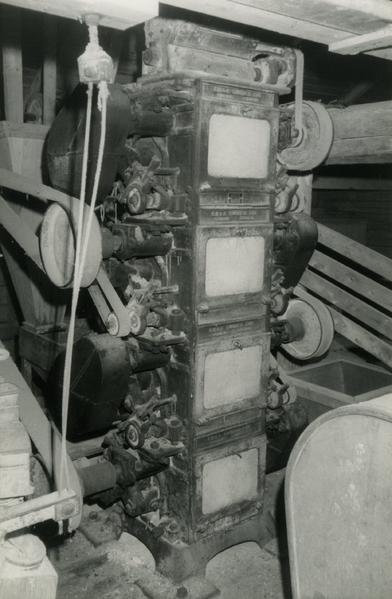

Further changes soon took place within the firm, as E. R. & F. Turner stopped producing steam engines in 1908, and focused on the production of milling machinery. By this time, the firm had already completed many mill installations. These included small plant installations, such as a 3 sacks per hour installation in Botley Mills, Hampshire in 1892 (an image of Turner machinery in the mill from 2011 on the right). The firm also installed some bigger plants, such as a 40 sack per hour plant for Richard Baxendell & Sons at their Sun Flour Mills in 1906. This mill was then sold to the CWS two years later and would be credited as having the largest capacity in Britain in the 1930’s. It was also common for the firm to be re-hired to update or expand installations. Messrs F. Skurray & Son’s Mill in Swindon was such an example. The initial installation in this mill took place in 1892, but then in 1903, a completely new and larger plant was installed. To read more about this mill and the installations, click here.

The Turner firm also cultivated a business abroad. Frederick Turner visited Europe and the Colonies on behalf of the firm and had success, as shown by the image, left, of roller mill parts in a watermill in Finland. Furthermore, in 1887, the firm established a branch office in Johannesburg. Along with this office, Charles Thomas Roberts, who had been a draughtsman for the firm in Ipswich from 1880, was appointed to represent the firm in South Africa, a position he retained until 1891. The business in this country was particularly fruitful, especially in the supplying of mining machinery for the gold mines in the Transvaal

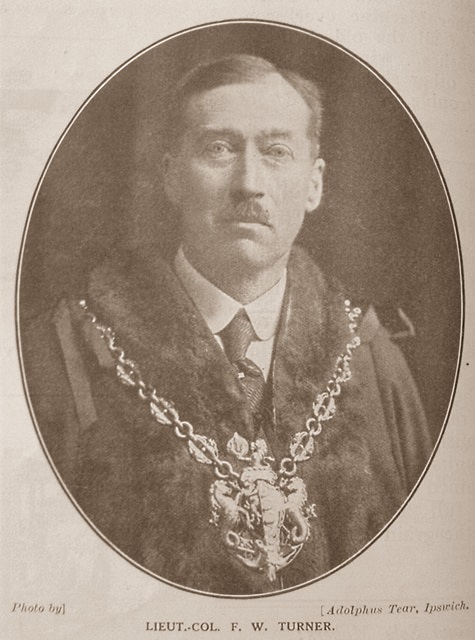

The events of the First World War stopped the success of the firm, as regards the milling industry. The engineering works became converted to produce goods for the war effort. This included producing a ‘single purpose lathe for the accurate production of shell bodies’, which had been designed by the works manager, Mr. Arthur Leggett (Filby, p.48). Due to their success, around 2,000 similar machines were produced for plants all over the country. Meanwhile one of the directors of the company, Frederick William Turner, son of Frederick Turner, was a member of the Territorial Army when war broke out and found himself sent to France as Second in Command of the 4th Territorial Battalion of the Suffolk Regiment in 1914. During the course of the war he would fight at the second battle of Ypres, where he was wounded, and then be promoted to command of the 4th Suffolks.

After the conclusion of the war, the firm faced a time of uncertainty and instability. They had lost most of their export business and the demand for manufactured goods had declined. As such, the firm made the decision to join the Agricultural & General Engineers Ltd (AGE) in 1920. This combine of British engineering companies took over the entire share capital of the firm. However, this association did not have great success. Four years after its formation, its loss was £252,125. By 1931 there were calls for an independent inquiry into the running of the company and a year later five members, including Arthur Leggett, resigned from the Board. Due to a shortage of liquidity, a receiver was appointed and each constituent company was then sold. E. R. & F. Turner became independent again and also acquired Bull Motors Ltd., which had joined AGE in 1925.

Despite difficulties with ownership, the firm itself was still thriving. In 1922 they had purchased a nine acre site on Foxhall Road. The move and opening of this new site only took place in 1937, coinciding with the firm’s centenary. Also in 1937, E. R. & F. Turner gained an important new client, the firm of Weetabix. During the 1920’s E. R. & F. Turner had become known for their production of flaking mills, both for animal feed and breakfast cereals. Weetabix purchased one of these mills and today, 90% of the flaking mills in their Burton Latimer and Corby plants are provided by E. R. & F. Turner.

The commencement of the Second World War saw the firm once again convert to producing lathes for shells. Given the acquisition of Bull Motors Ltd., they also produced electric motors which were used in various ways, including for radar equipment and bomber flap operating gears. However, the firm still retained some milling business during the war, as they produced machinery for the separating, cleaning and drying of flax. Flax was an important crop and pivotal in the production of linen. However, as imports into the country were being prevented, Britain had to start producing the crop and E. R. & F. Turner produced the machinery to help with this ‘new’ industry.

With the end of the war in 1945, the firm decided to start producing new machinery, including a completely enclosed roller mill and a new flaking mill. This machinery was still very popular throughout the latter half of the 20th century and were produced in ever increasing sizes, including 550mm and 600mm diameter roller mills and the 600, 550, and 460 model flaking mills. These flaking mills have found a worldwide market and can be found today throughout the world in Europe, Australia, New Zealand, South America, Middle East, Kenya, South Africa and Canada.

Whilst production was still running successfully, the firm went through other changes in ownership. After AGE was wound up in 1932, the firm of E. R. & F. Turner had been under the ownership of the Leggett family. They sold the firm to the investment company, Forgeway Finance, in 1966, who liquidated much of the property. However, in 1969, W. G. Gosling & Sons Ltd. purchased E. R. & F. Turner, including J. Harrison Carter. This purchase saw the manufacturing firm move to a new site on Knightsdale Road, where the company continued to thrive and produced much of the new machinery already mentioned.

Today, E. R. & F. Turner is still owned by the Gosling family, but has been amalgamated with two other firms. In 1986, Miracle Mills Ltd. of Penge came up for sale. They produced similar machinery to the Harrison Carter range, so was purchased by E. R. & F. Turner. The firm was relocated to Ipswich and a new range of hammer mills were produced by the Miracle Mills brand. The second firm to be acquired was Christy Hunt (Agricultural) Ltd. of Scunthorpe. It was purchased in 2002 and also relocated to Ipswich. They continued to produce hammer mills, pulverizers and grinders. With the acquisition of this third firm, the three groups were turned into one trading company, Christy Turner Ltd. However, this was seen as causing confusion for consumers who thought the old brands no longer existed so in 2016, there was another rebrand so the three firms appear individually under the Christy Turner umbrella. So it is that the 181 year history of the E. R. & F. Turner firm continues today.

Sources:

‘Charles Thomas Roberts Obituary’, 1919 Institution of Mechanical Engineers (December 1919), p.915, https://www.gracesguide.co.uk/Charles_Thomas_Roberts accessed on 24/01/18.

‘Edward Rush Turner Obituary’, 1904 Institution of Civil Engineers: Obituaries, Volume 156, https://www.gracesguide.co.uk/Edward_Rush_Turner accessed on 24/01/18.

‘Frederick Turner Obituary’, 1914 Institution of Mechanical Engineers (February, 1914), pp.216-217, https://www.gracesguide.co.uk/Frederick_Turner accessed on 24/01/18.

‘The Mayor of Ipswich’, The Miller, January 5 1925, p.960.

E. R. & F Turner, Centenary Catalogue: Flour & Provender Milling Machinery (Ipswich, 1937).

Filby, Lyndsey, ‘175 years of sound British engineering’, Milling and Grain, Vol. 127, Issue 2, (February 2016), pp.46-52.

Forrest, James (ed.), Institution of Civil Engineers, Corn-Mill Machinery (London, 1882).

Harris, Nigel S., Wheat flour Milling from Millstones to Rollers (2017).

https://www.gracesguide.co.uk/AGE_-_Agricultural_and_General_Engineers