Manufacturers: Edward P. Allis & Co.

What follows is a slightly edited article written by Mildred Cookson, reproduced here with her permission, that was first published in Milling and Grain in December 2016:

Research for my article…on our milling engineers and the milling revolution, led me to discover that The Miller during 1885 published illustrated descriptions of several milling engineering works. The 7 September issue reported on a visit to the Bay State engineering works of the American firm of Messrs. Edward P Allis & Co in Milwaukee, Wisconsin.

The Journal underlined the historical and enduring importance of milling engineers; at that time they were revolutionizing new machinery and competition between them was ever more intense. The machines of Edward Allis, an eminent firm of engineers and millwrights, not only were to be found in every part of the United States, their reputation had spread world-wide. They manufactured on a scale second to no other American firm, and were among the first makers of roller mills in the USA. In 1885 the firm had been agents for Wegmann porcelain rolls for the previous seven years. They were also fortunate in securing the services of Mr. W. D. Gray another eminent milling engineer, and the inventor of the well-known roller mill bearing his name. It was noted that such was the extent of orders received that all the workshops on the premises were working double time. This in the face of the prevailing depression in American millwrighting speaks volumes for the firm. They had over 30 milling contracts in hand, not only roller mills but other special machines.

Disaster and triumph

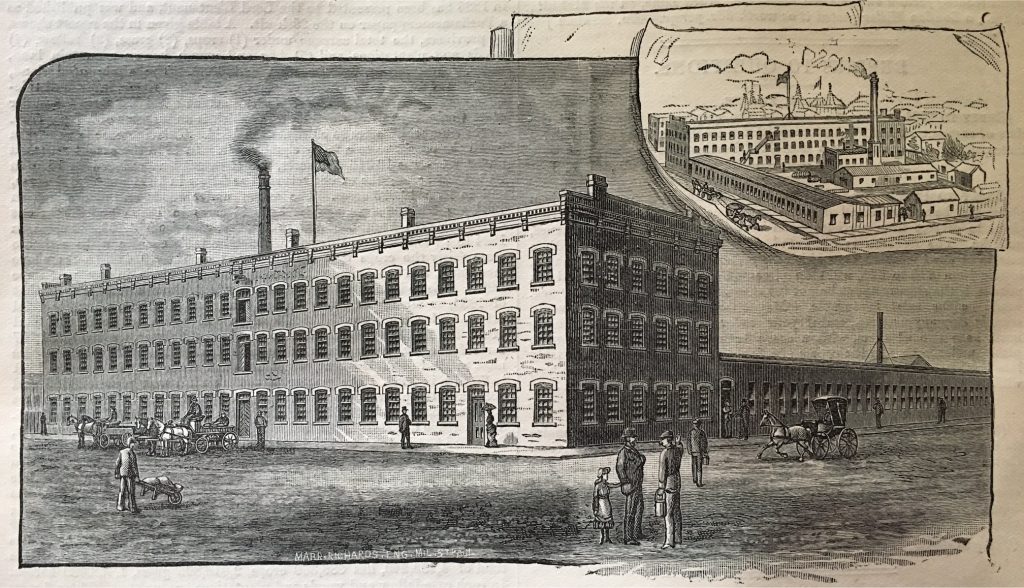

Many years earlier William Goodnow had started a small machine shop and foundry at the corner of Florida and Clinton Streets. By 1885 that site had been taken over by the Cream city Iron Works. Mr. Goodnow had been fairly successful and he was determined that his new Bay State shops would be the best and most perfectly equipped machine shops in the west. Having secured the location at the corner of Lake and Barclay Streets, he put up a three-storey brick building with engine room, blacksmith’s shop and foundry adjoining The whole establishment was supplied with an extensive and complete outfit of tools, patterns etc., and work began on a large scale.

In a short time it was found that the works, built in an excess of business rivalry, were far in advance of their legitimate trade requirements and the institution became heavily involved and finally hopelessly bankrupt. After various ineffectual attempts to operate them by receivers and the assignee, they were finally sold, to be purchased as a speculative investment, by Edward P Allis, owner of the Reliance Works already a thriving business. The Bay State works were to remain idle for several years, leased for a period to the Chicago, Milwaukee and St Paul Railway Company and were used as their repair shop.

In time business grew and the site was reclaimed. The firm had an excellent write up in The North-Western Miller describing the Bay State premises as occupying the half block fronting on Barclay Street, between Lake and Oregon Streets, Milwaukee. Extra capacity was provided by the firm’s Reliance Works, operating on a separate site but under the same management. The main site made Gray’s famous noiseless roller mills, with the castings and the woodwork for the machines provided by the foundry and woodworking shops of the Reliance Works. For months at a time their daily output reached eight to ten complete machines.

A thriving business

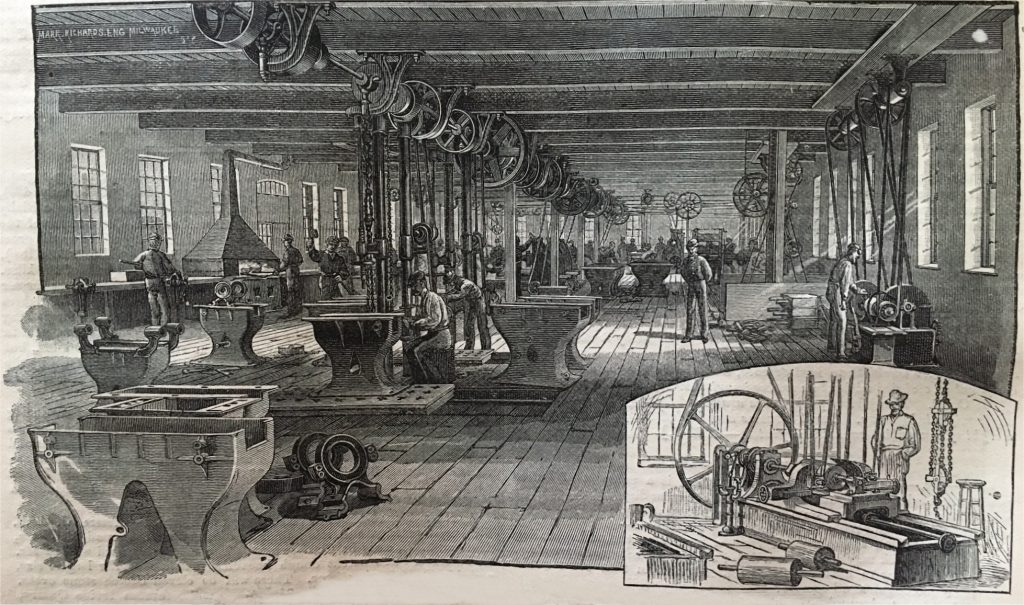

The main building of the Bay State Works was built of cream coloured bricks, 200 feet long by 50 feet wide and of three storeys. The first floor held the roller mill frames brought from the foundry and fitted for receiving the wooden hoppers and the minor details of iron work involved in the construction of the machines. The floor was designed and equipped with special tools, each designed to do the maximum amount of work with a minimum amount of labour. Special lathes, planers, drilling machines were all kept busy, tended by skilled mechanics each specially trained to do his share of completing the building of the machines. The floor also housed the special tools for turning, grinding and corrugating the chilled iron rolls that were the prominent feature of all roller mills.

The firm about this time started to manufacture the rolls themselves, with the works fully equipped for this purpose. Even so only a limited number of rolls were produced here, the greater proportion coming from Ansonia and Wilmington. All possible care was taken to insure perfection in workmanship. As a result of their reputation, rolls were sent to the works for refitting from St. Louis, Cincinnati, New York, Cleveland, Minneapolis and other milling points.

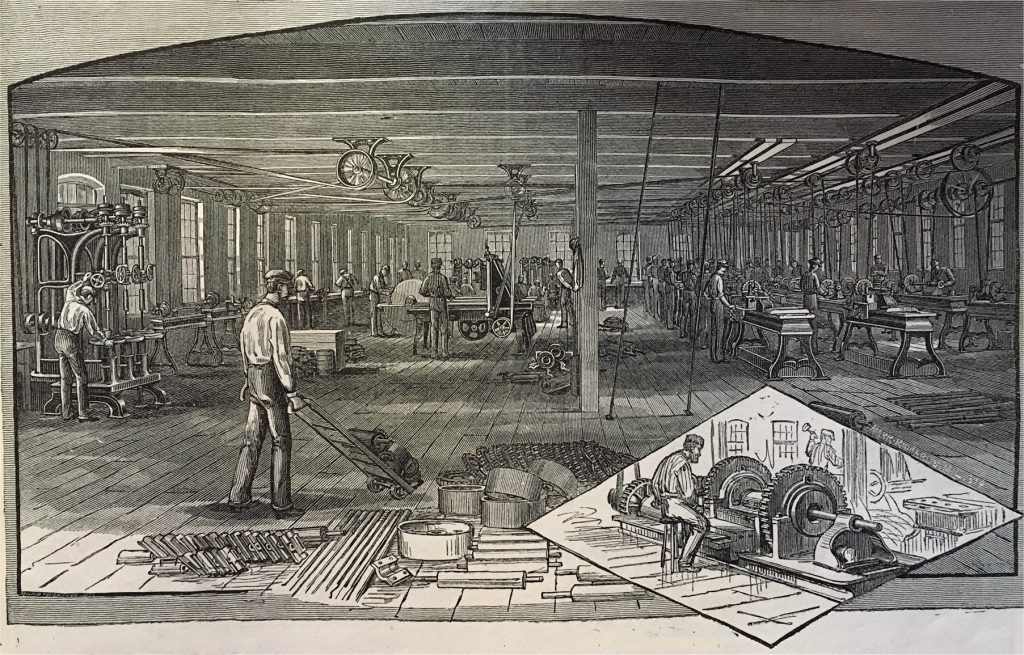

Ascending an elevator to the second floor, a visitor would see long lines of lathes, planers and drill presses, the whole room thronging with busy workmen. This floor was devoted entirely to the fashioning of the smaller pieces of iron work required to complete the machines. Hand wheels, bolts, rods, levers, feed rolls, boxes etc., each had their own appropriate machine and all moved together like clockwork. Also on view were the lathes and grinding machines for fitting up the Wegmann porcelain rolls. The third floor was fitted out with pulley lathes and grinding machines and was also used as a storeroom for finished pulleys etc. By 1885 the workforce was averaging over two hundred trained mechanics, working solely on the Gray roller mills.

Returning to the first floor, the visitor would enter the finishing room. Machines here were fitted with the woodwork, painted and prepared for shipment. All machines for which orders had come in, and were finished, left the premises immediately. At the time, notwithstanding the low price of wheat and depressed conditions in the milling industry, production was over one hundred machines behind orders. During the years 1880 – 1885 nearly fifteen thousand machines had been built and shipped from these works, going to all parts of America, as well as England, Australia, New Zealand and South America. This firm fairly illustrates the magnitude of the milling industry at that time and was of interest to millers from all parts of the world.