Manufacturers: Briddon and Fowler

The history of Briddon & Fowler actually starts with the engineering firm Henry Simon Ltd. In 1885, George Briddon joined the drawing office staff of Henry Simon, under the direction of George Huxley. After Huxley was promoted to Managing Director in 1900, George Briddon became head of the Drawing Office. Robert J. Fowler, on the other hand, joined the firm in 1889 and succeeded the ‘milling expert’, William Stringer, after his death in 1893. The skills and attributes of these two men helped make Henry Simon Ltd. a success. However, in 1902 they left Simon and set up their own firm, ‘Briddon and Fowler’. The reasons behind this move are unclear, but the uncertainty that followed Henry Simon’s death in 1899 appears to have been one motivating factor behind it.

Whilst Briddon and Fowler may have been a new firm, they continued Henry Simon Ltd. practices. They decided to focus on the design aspect of the machinery and then contract out the manufacturing of the machines to another firm. They established an agreement with Bernard Samuelson, who’s Britannia Works in Banbury gave the Briddon and Fowler machinery the name ‘Britannia’.

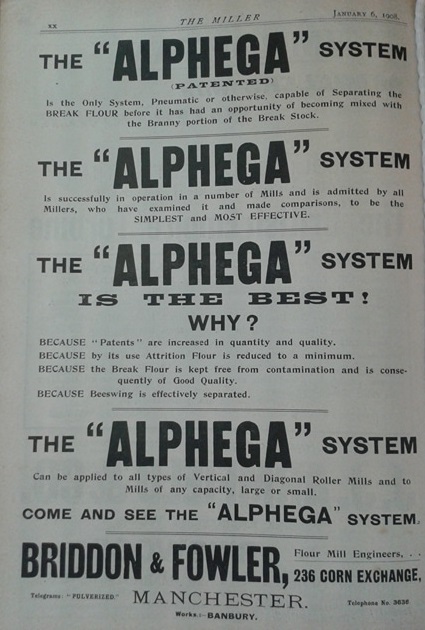

Whilst their Britannia rollers, Britannia purifiers, Britannia centrifugal dressing machines, and many other Britannia designs were popular and ordered by multiple clients, it was arguably their patented ‘Alphega System’ that they became better known for. This ‘Alphega System’, so named as it was ‘the alpha and omega of the break flour problem’ was patented c.1906/7 (Jones, p.256). The system was ‘the simplest solution to a well-known but previously intractable problem’ of preventing the impurities released from the first break from contaminating the rest of the flour (Jones, p.256). Fowler regarded that ‘heavier material leaving a pair of diagonal rolls was projected strongly from the nip, while break flour and other small particles dropped short’ (Jones, pp.256-257). As such, partitions were arranged within the machine to separate the break flour. This scalping design was viewed as the most efficient and soon Briddon & Fowler could boast that it was ‘successfully in operation in a number of mills’ (TM, January 6, 1908, p.xx).

During these early years when their machinery was made by Samuelson, the firm made many installations. Indeed, by 1906 they claimed that there were 34 mills working on ‘Fowler’s System’, including Joseph Rank Ltd. Premier Flour Mills, London; Messrs. Bolands’ Ltd. Ringsend Road Mills, Dublin; and Messrs. Wm. Marshall & Sons (Grimsby) Ltd. Victoria Flour Mills. Another mill they installed machinery into around this time was Messrs. G. W. Chitty & Co. Ltd. Charlton Mills, Dover. When The Miller published a report about the mill in January 1907, they were very complimentary about the work Messrs. Briddon and Fowler had accomplished. They claimed that the firm must have ‘undoubtedly studied their clients’ requirements very closely’ and thanks to this close study ‘there is mutual satisfaction and benefit’ (TM, January 7, 1907, p.709). Indeed, they believed the work accomplished there ‘added still further to their reputation’, in reference to Briddon and Fowler (TM, January 7, 1907, p.709). With praise such as this and adverts appearing regularly in milling publications, it is unsurprising that the firm flourished and they continued to receive orders for their machinery, not just from Britain but from foreign clients too.

The next major change to take place within the company took place in 1908. On 7 September, 1908, an announcement appeared in The Miller:

‘Messrs Briddon and Fowler report that they have secured works at Bredbury, near Manchester, where in future they will themselves manufacture their own flour milling machinery. They have also registered their business as a private limited company, under the style of “Briddon and Fowler, Ld.” There will be no change whatever in the management of the business, and Mr. Briddon and Mr. Fowler have been appointed managing directors.’

Briddon and Fowler were now to produce their own machinery in Bredbury at a location chosen for its convenient proximity to a railway siding, allowing them access to the national rail network. The company had also been registered, with a capital of £50,000 divided into 50,000 shares of £1 each. However, the running of the business remained the same with Mr. Briddon and Mr. Fowler still in charge.

The firm of Briddon & Fowler Ltd. continued to thrive after this change. By 1914 they could claim to have installed the ‘Alphega System’ in 42 mills in Britain and abroad, with many other ‘Britannia’ installations as well (Harris, p.71). However, the following year it was announced in a Henry Simon Ltd. ‘Occasional Letter’ that they had ‘come to an agreement with Briddon and Fowler Ltd. under which Messrs. Briddon and Fowler personally have rejoined our staff’ (‘Occasional Letter’, March 1915). So it was that Briddon and Fowler was amalgamated by the firm that its founders had left thirteen years earlier. The reasons behind this amalgamation are not known but ‘it appears to have been on the basis of a mutually amicable arrangement between both firms’ (Harris, p.71). By 1916 Simon Ltd. could already report to having installed an Alphega Plansifter as the work of Briddon and Fowler continued to be appreciated by many millers.

Read about Caudwell’s Mill, where Briddon and Fowler machinery was installed in 1905, here.

Sources:

Harris, Nigel S., Wheat Flour Milling from Millstones to Rollers (2017).

Henry Simon Ltd. Occasional Letter, March 1915.

https://briddonandfowler.weebly.com/

The Miller, January 6, 1908.

The Miller, January 7, 1907.

The Miller, September 7, 1908.