Manufacturers: MM. Rose Frères

What follows is a slightly edited article written by Mildred Cookson, reproduced here with her permission, that was first published in Milling and Grain in January 2017:

I am continuing to mine the rich seam on milling engineering works described in The Miller during 1885. Each features the manufacture of “milling machinery and appliances belonging to the miller’s art”. The 5 October issue featured the workshops of the French firm MM Rose Frères at Poissy in the department of the Seine-et-Oise.

This remarkable firm started from a comparatively modest beginning in 1865 to become 20 years later one of the most important millwrighting factories in France. Messrs Henry and George Rose, the owners of this important company, started in business around 1860, and during the whole of their professional careers were noted for steadily keeping abreast of mechanical progress in the miller’s art. They were, in effect, to the manor born, for their father, Mr J Rose, lived in England and was himself a miller. The two brothers were regularly trained to follow their father. This gave them the practical knowledge of, and sympathy with the work of the miller, which they would have acquired in no other way.

It is interesting to note that the two brothers were nephews of one of the most eminent UK millwrights of that time, George Packham, who designed the Ville d’ Eu Mills for King Louis Philippe of France and whose business relations with that monarch ripened into a lifelong friendship. An item on this in the 3 September 1877 issue, p337 may allow me to write more on this topic in the future.

Among the early achievements of MM Rose Frères was the introduction into France of a millstone balance. This was in 1861 when their father was still a miller at Epouville, near Le Havre. The father and two sons joined forces to work on the patent balance for millstones which was sold under the name MM Rose, Père et Fils, only changing some years later to the present title.

During the next five years members of the firm travelled extensively, visiting numerous mills in France and other countries. They returned home convinced that a great future lay before wheat cleaning machinery. They were all struck by the irreparable injury that flours ground from high class wheats received from the contamination with earth and other foreign bodies which were originally mingled with the raw grain and were triturated past all hope of elimination in the grinding process. They acquired the French patent of the “Childs” aspirator and at once made it their business to push this celebrated wheat cleaner with all their energy. The Tarare Americain (American Winnower), as this machine was called, met with great success and its makers were soon in a position to quit the modest workshop which they then occupied at Maromme near Rouen. They then started on a more ambitious scale in the ancient town of Poissy, just twenty miles outside Paris and on the railway connecting Rouen and Paris.

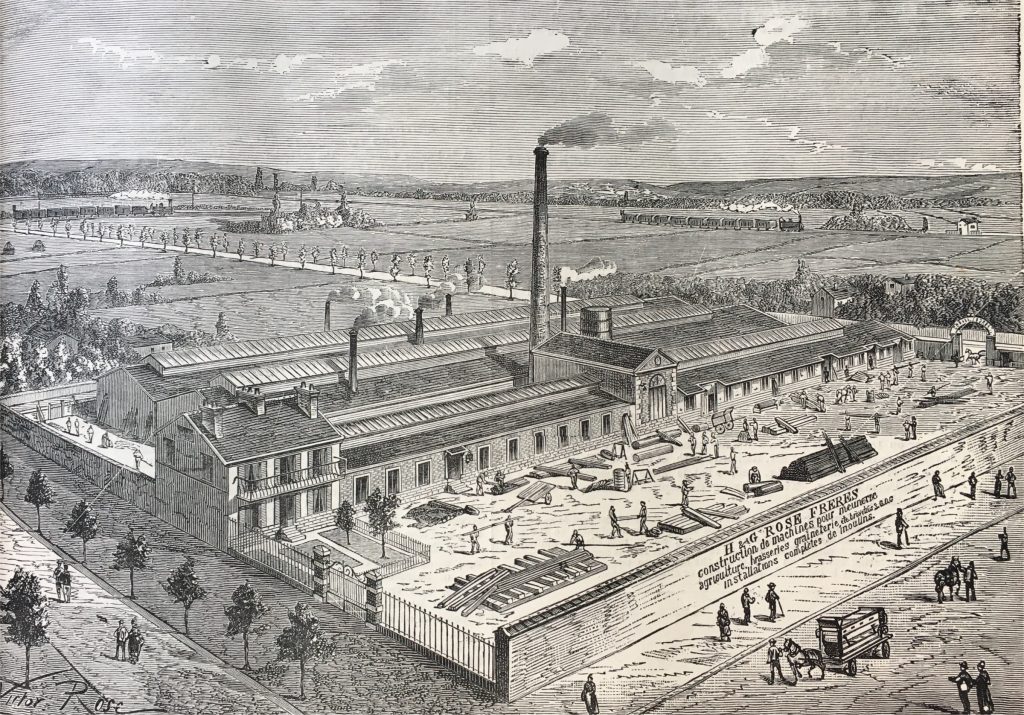

This illustration shows the Poissy workshops which had expanded since its foundation in 1865, so that by 1885 it was second to no other factory of the same kind in France. Production within the factory covered every description of machinery used in flour mills, breweries and distilleries. At the same time the wants of the workforce were well cared for. The works covered 7,000 square meters, of which 4,500 were occupied by workshops employing 200 workmen. The motive power of the factory was supplied by a fine engine of 50 horse power, supplied by Messrs. T Powell & Co., of Rouen.

Since the success of their Tarare Aspirateur the firm made wheat cleaning machinery a specialty and kept in touch with every improvement, wherever they found it in this area of milling mechanics. Dressing of flour also received their special attention. They were the first to introduce into France the centrifugal bolting machine as well as scalpers, all of which were readily taken up by the milling trade. It was stated that between 1865 and 1880 the firm sold more than twenty five thousand machines.

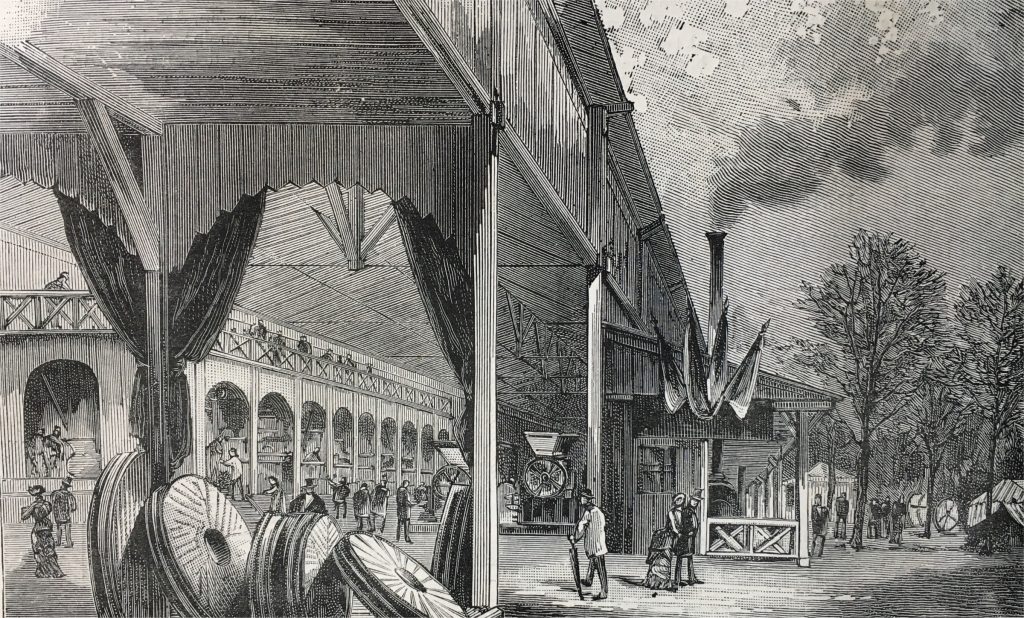

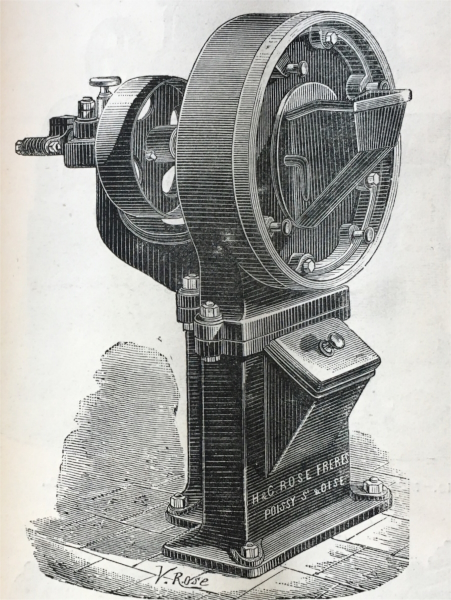

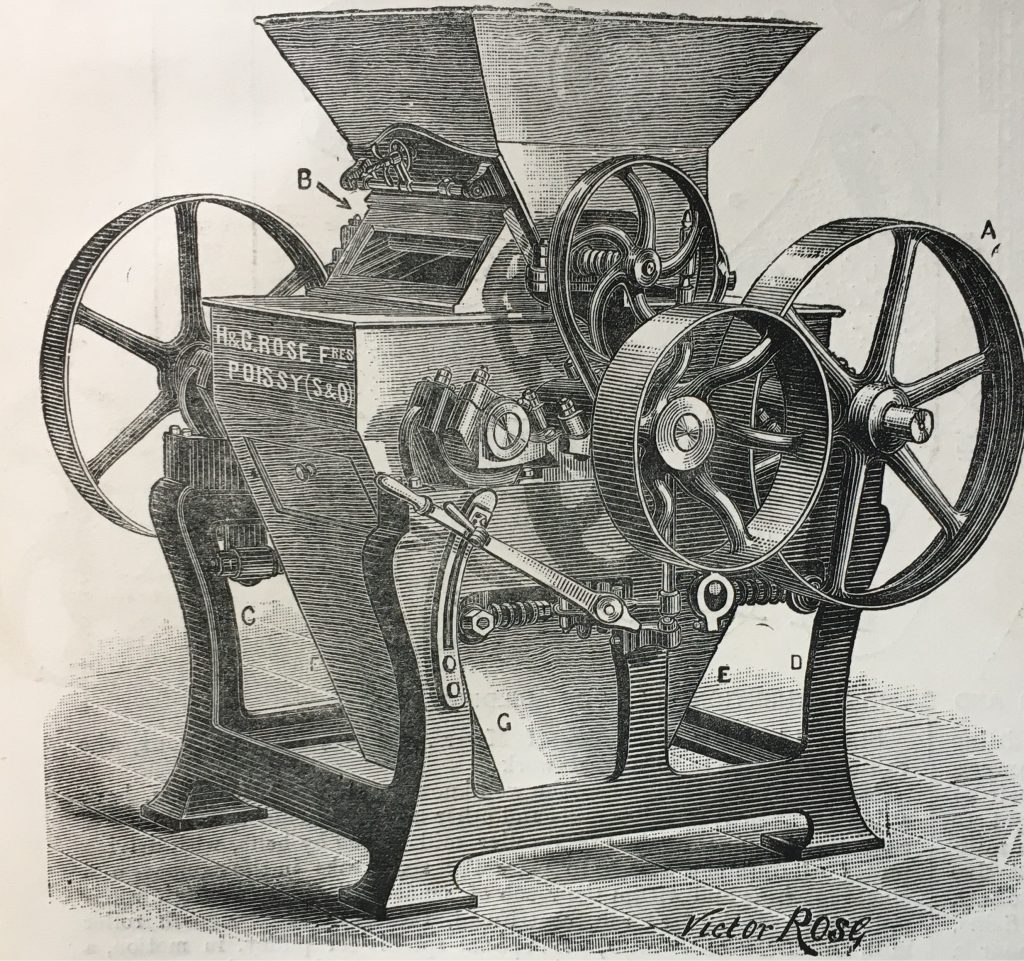

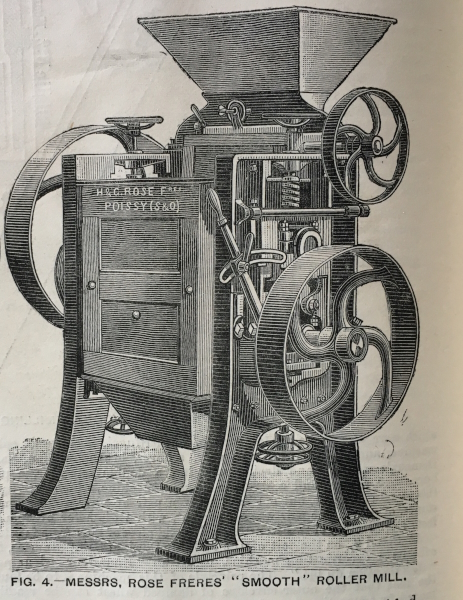

MM. Rose Frères did not neglect the reduction of grain by millstones. They took across the Channel the disc mill of Messrs Higginbottom and Stuart of Liverpool for breaking wheat, and fitted it in some important mills in France. They made roller mills, both corrugated and smooth, and visitors to the Milling Exhibition at Paris in 1885 would have been struck by the solid and handsome structure of the mills on their extensive stand.

Break and Smooth Roller Mills

They showed two distinctive systems of milling in actual operation. In both, the grain was put through a very complete system of cleaning, but in one it was treated with six breaks, two of which were carried out with discs, and the remaining four by roller mills, and in the other it was subjected to three breaks on discs, and then passed through a smooth roller mill. The exhibition stand at the Exhibition must have impressed the judges as it was awarded with a Diploma of Honour.

They were continually being awarded medals at various International exhibitions in which they took part. As early as 1865 the firm took a first-class prize at Houdan in France, three other prizes at local exhibitions, and a silver medal at Lyons in 1872. A diploma of honour at Vienna in 1873 and the distinction of a Gold Medal in 1884 at the Brest Exhibition. They were also classed “Hors Concours”, being judged as beyond competition at Rouen in the same year.