At the Mill: Milling Process

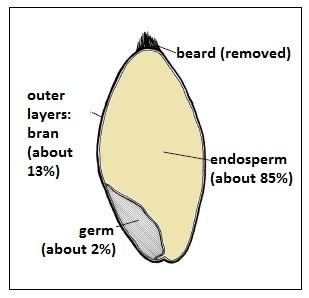

The main purpose of milling is to create flour from the raw product of wheat. To accomplish making white flour, the bran and germ must be separated from the endosperm (see image above). Once the endosperm is free from the bran, it is then further reduced until the flour is uniform and fine.

The adoption of rolls and other machinery, such as plansifters and purifiers, meant that this task was made much easier and finer, whiter flour could be ground. Following is a description of this milling process:

First Stage: Break Roll

At this stage, the cleaned wheat is passed through the first set of rolls, the break roll. These rolls are usually fluted and ‘their purpose is to open up the wheat grains as gently as possible’ (Harris, p.52). This is to ‘shear open the wheat grain and scrape the endosperm from the bran’, so starting the separation process (Harris, p.41).

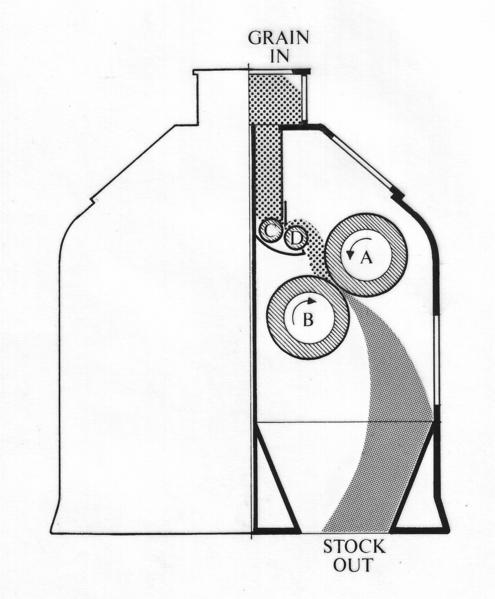

Rollers work as the wheat passes through them. The two different rolls turn in opposite directions and operate at different speeds, one slow, one fast. The slower roll holds the grain whilst the faster one strikes at the grain as it passes through. The severity of the strike can be controlled by the space between the two rolls which can be adjusted by the miller.

Break rolls are also are usually placed on an angle as the flutes are more effective that way. The spiral is usually 12 degrees and care must be taken that both rolls are on the same angle.

Second Stage: Plansifter

Once the grain has passed through the break roll, the large pieces of endosperm and bran go through the first round of sieving in the plansifter. This process was described by Graeme Walker when writing an inventory of machinery at Caudwell’s Mill: ‘From here it falls into a hopper beneath the rolls and then into the elevator boot which takes it up three floors, to the plansifters’ (Walker, p.1). It is here that the separation of the bran and endosperm takes place.

The plansifter is basically a sifting machine with multiple sieves placed above one another. From the outside it looks like a vibrating box attached to the ceiling by steel rods. Inside, are a series of sieves which become finer further down. The top ones may be made of stainless steel mesh and then further down, nylon, or traditionally silk, could be found. Under each sieve, there was usually a ‘brush running on an elongated oval track fixed to the tray’ (Harris, p.43). This would brush the stock through the sieve, if it was fine enough it would pass through, if not it would overtail and go back to a roll. Today, modern sieves more commonly have ‘several free moving triangular shaped pucks moving between the sieves to keep them clear’ (Harris, p.43).

Once again, there is a good description of this process from Caudwell’s Mill:

‘The 12 sieve trays have a coarse sieve at the top and the sieves get finer as they approach the bottom of the unit. The coarsest sieves are a wire mesh with holes about 5/64 inch (2mm) square and the finest are nylon (formerly silk) that can hardly be seen…Under each sieve is a brush running on an oval track. This brushes the underside of the sieve and causes the stock to be brushed through the sieve. If the stock is fine enough it will fall through the sieves and pass into the flour worm ready to be bagged, otherwise it overtails (passes over the sieve) and goes back to a roll.’ (Walker, p.11)

And so the product that overtails is now ready to go through another set of rolls, the reduction roll.

Third Stage: Reduction Rolls and Purifier

The reduction rolls are where the overtail goes post sieving. Unlike the break roll, these are not fluted. Instead, ‘the surface of the rolls is slightly rough allowing them to gently scrape the endosperm off the bran’ (Harris, p.53). This further separates the two and endosperm is ground even finer.

After passing through these rolls, it then goes through another sieving process to remove the bran. This could mean a return to the plansifter or the use of a purifier:

‘Purifiers are used to extract the finest bran particles from the endosperm (flour). The flour is fed onto a sloping sieve which shakes; air is drawn through the sieve, lifting the fine bran and depositing it onto the trays. From here it is brushed off and returned to the mill. The flour falls through the sieve, is collected, and taken to the next process.’ (Walker, p.11).

This process of passing through the reduction rolls and then being sieved can be repeated many times. Indeed, the ‘reduction system may consist of 12 to 15 grinding stages’ until eventually the endosperm and bran are completely separated and the endosperm has been ground into a fine, floury powder (Harris, p.55). This flour is then taken away to be bagged and packaged ready for sale.

This, therefore, is a basic description of the milling process using roller machinery showing how wheat grains are turned into flour.

Sources:

Harris, Nigel S., Wheat Flour Milling from Millstones to Rollers (2017).

Walker, Graeme, ‘List of machinery in Caudwell Mill’ (2002): CAUD-06916.