Sugar mills

Mildred Cookson

Summary

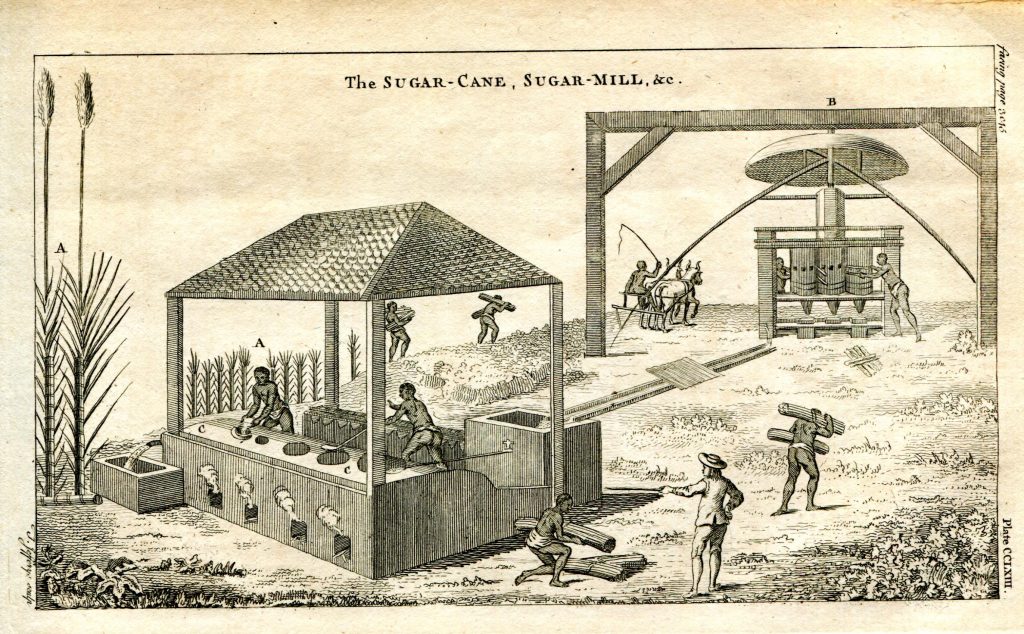

Sugar is produced from juice extracted from the sugar cane. In sugar mills sugar cane was crushed between rollers. These could be powered by hand, animal power, wind or water. In the 18th-19th centuries much of the sugar consumed in Western Europe was produced by slaves on the plantations in the Caribbean.

Details

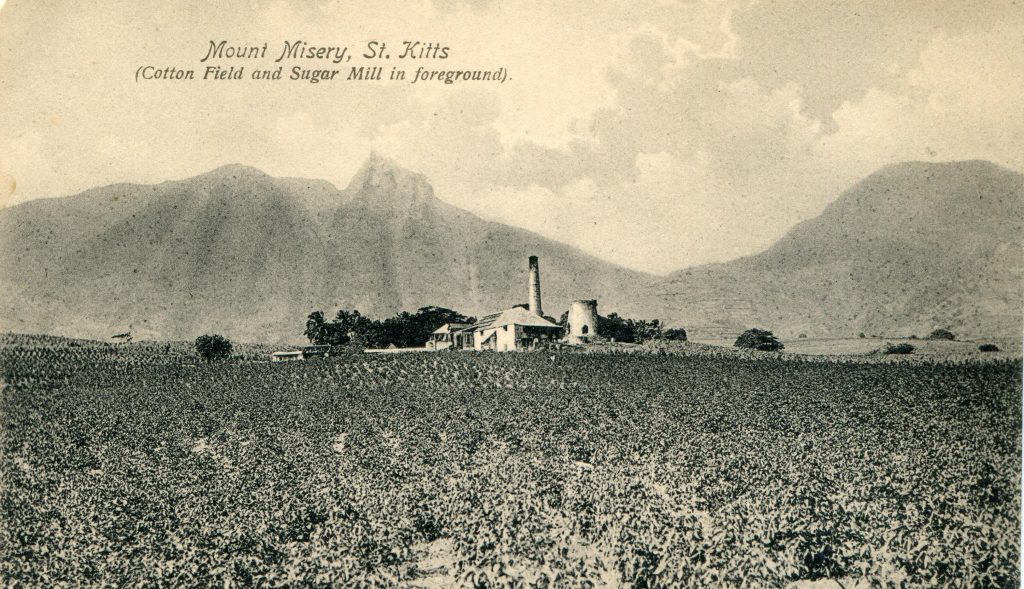

Sugar is produced from juice extracted from sugar canes, a process originally carried out by hand or animal power, and later by wind and watermills. Sugar was the main crop produced on plantations throughout the Caribbean in the 18th, 19th, and 20th centuries. Most islands were covered with sugar cane fields and sugar mills. These plantations produced 80 to 90% of the sugar consumed in Western Europe.

The history of the sugar industry is tainted by slavery. Much has been written about the technology and about the plantations as well as more recently the slave trade and its impact. The Mills Archive feels very strongly its responsibility to highlight social issues as well as those of technology and will continue to look after documents that cover all aspects of milling over the centuries.

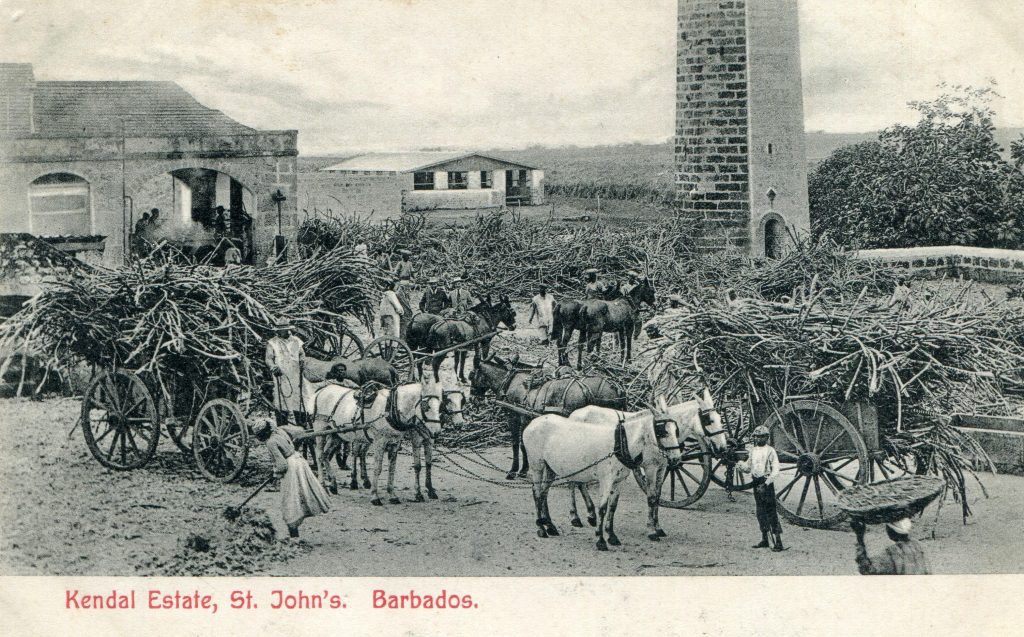

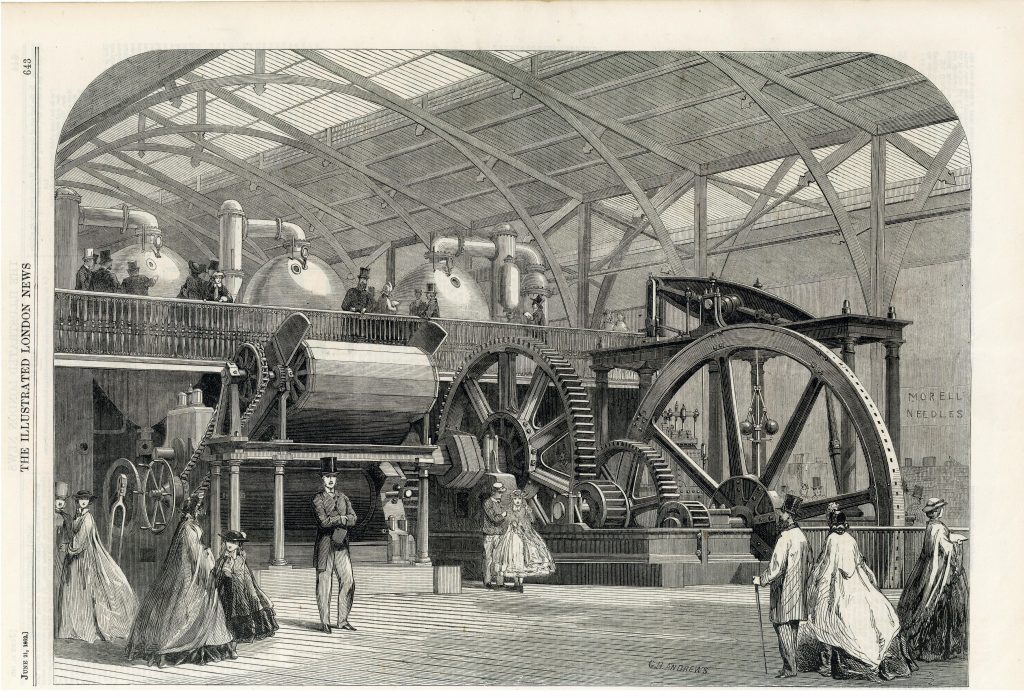

In the sugar mills the cane was squeezed through a set of 3-6 heavy rollers. Originally they would have been vertical wooden rolls, replaced by steel ones as the process evolved. This produces the juice which can then be refined to make sugar. It was important during the harvest season that the mill worked day and night, except for emergencies when the cane got jammed in the rollers. Once the cane is cut the juice starts to flow and the canes must be put through the mill quickly, within 24 hours, or the juice will start to deteriorate and start fermenting, making it useless for production.

The process of crushing was a very dangerous one, it meant pushing the canes through the rollers and often hands got caught. In China stone vertical rollers were used, while in other countries vertical wooden rollers were used. In regions of India the rollers were set on the ground, and the process of feeding the canes into the rollers was done by standing in a pit alongside the rolls.

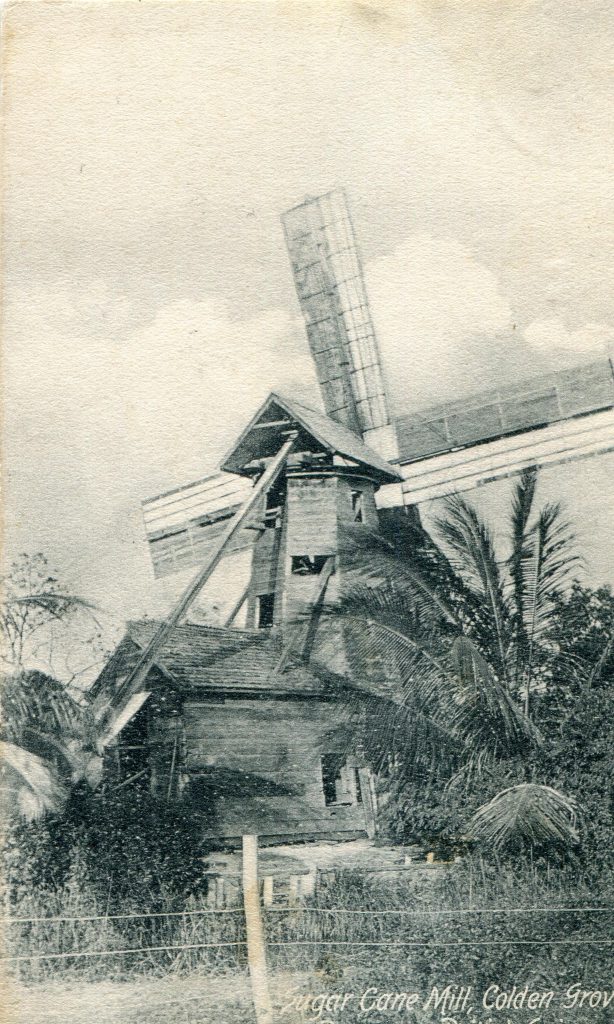

The windmills in the West Indies had their own terminology, the sails being called ‘points’. The windmills did not have a brake wheel, but depended on an operator to turn the mill, via the long tail pole, to 45 degrees out of wind when they wanted the mill to stop work. As well this the windmills had rings fixed at intervals into the walls, into which the two bottom sails (in the position of St Andrews cross) could be secured. During the hurricane season the points were taken down in case of damage, and stored until they were required to work again. The main arched opening for carrying the canes into the mill always faced west. In some places waterwheels were used for powering the rollers. Machinery used in the mid 19th and into the 20th century was chiefly made by British firms, in Scotland and Derbyshire. America also manufactured machinery.

Today, there are hundreds of derelict towers still standing as sentinels to the past, but only one windmill on Barbados has been repaired and put back to a working state, the Morgan Lewis mill. This work was carried out by the UK millwrights working under the supervision of David Nicholls and his team who undertook the repair on behalf of the Barbados National Trust.

Links

Further reading:

- Jones, Donald, Bristol’s sugar trade and refining industry (Bristol University, 1996)

- Vieira, Alberto, Slaves with or without sugar (Atlantic History Study Centre, 1996)

- Thomas, Hugh, The slave trade :The history of the Atlantic slave trade 1440-1870 (W&N, 1997)

- “Early Glasgow sugar plantations in the Caribbean” (Scottish Archaeological Journal, 1-2, September 2010, pp. 115-136)

- Other books in our library

Images and documents in the archive catalogue

List of sugar mills in our database

From elsewhere on the web: