Woad mills

Nathanael Hodge

Summary

Woad was the primary source for blue dye until the introduction of synthetic indigo. A small bushy plant, it was harvested by hand from August to November and crushed in a mill. It was also used to fix other dyes so they would not run. Woad was still used for police clothing and other uniforms at the beginning of the 20th century. The last English woad mills ceased work in the 1930s.

Details

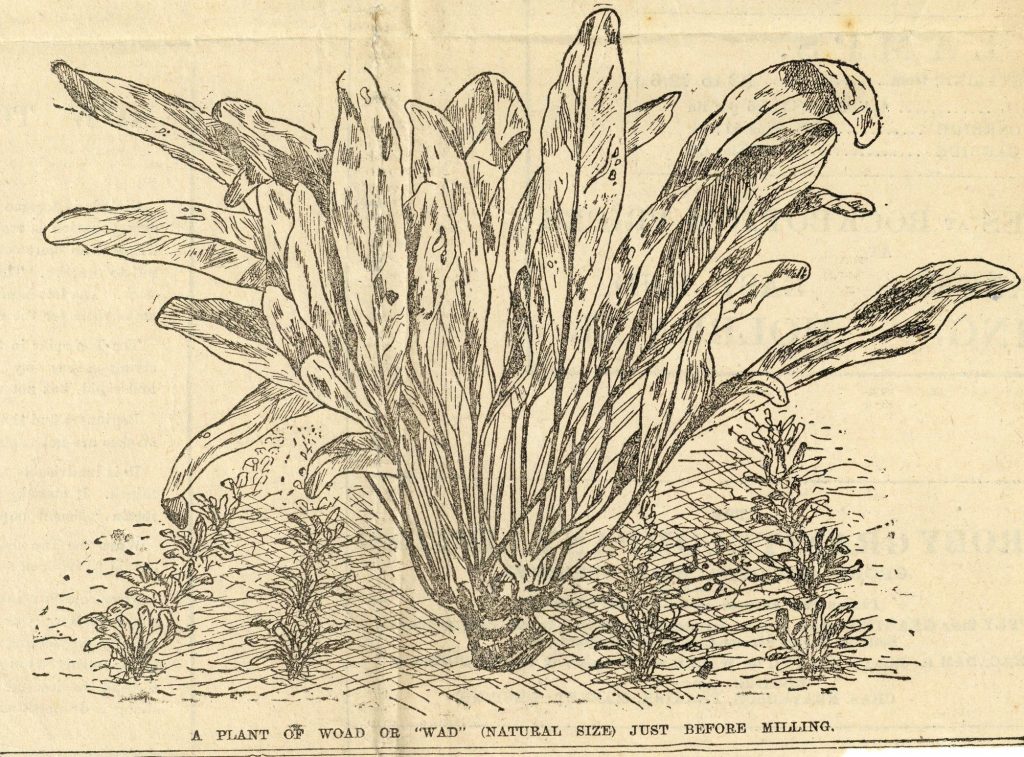

Woad (Isatis tinctoria), a small, bushy plant with tiny yellow cross-shaped flowers was once a primary source for blue dye, as well as being used as a ‘fixer’ to fix other dyes so they would not run.

The introduction of synthetic indigo caused the industry to decline, and by the beginning of the 20th century there were only three woad mills left in England, producing woad for the government to fix the dyes in police clothing and other uniforms. At Parson Drove in Cambridgeshire was the last of the old ‘peripatetic’ mills which at one time were moved every few years to new pastures when the old had been exhausted by the intensive nature of woad farming. Newer steam powered mills remained at Algarkirk and Skirbeck, Lincolnshire.

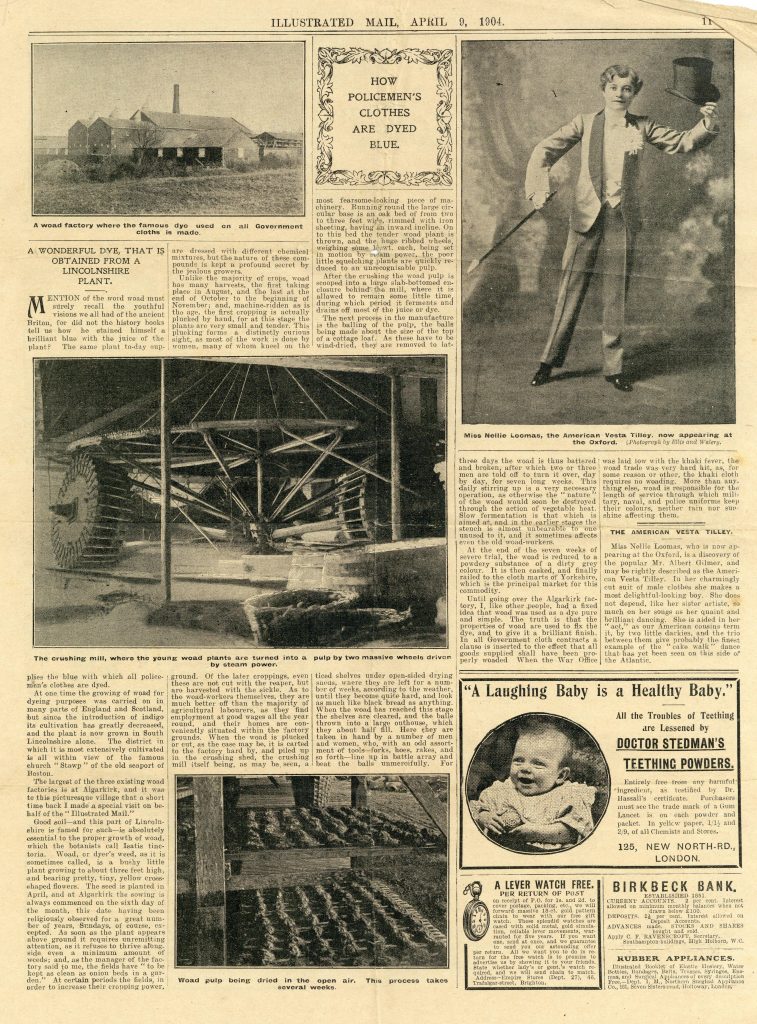

An article in the Illustrated Mail dated April 9, 1904 described the process of woad production as it was then carried out at Algarkirk Mill. Woad was planted in April. Sowing always began on the sixth of the month (unless this was a Sunday), and there were many harvests from August to November, the woad being cropped by hand or by a sickle.

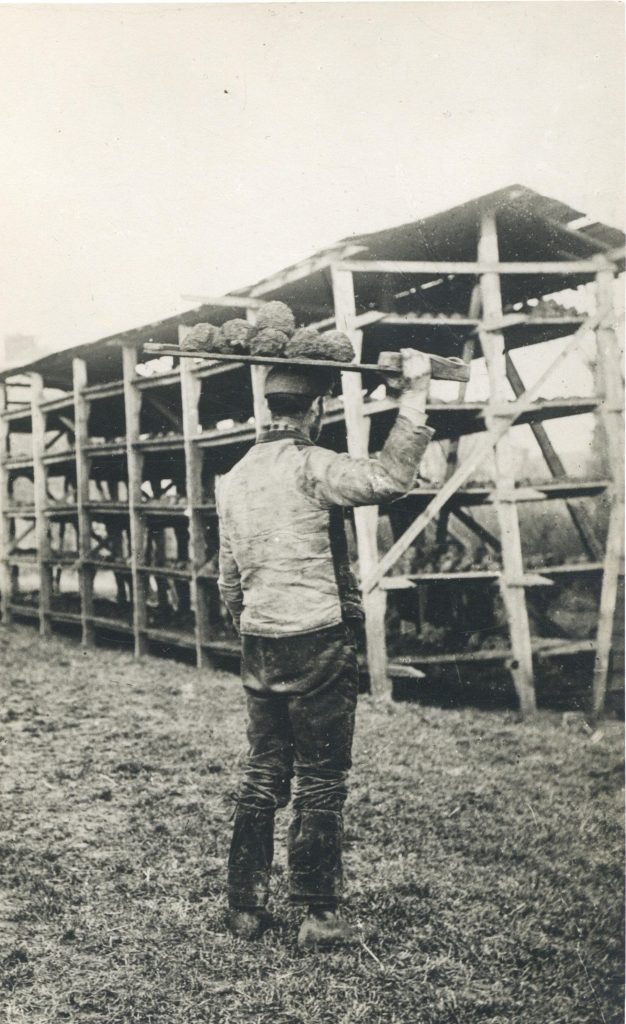

The mill consisted of a large circular base with an oak bed two or three feet wide, rimmed with iron sheeting with an inward incline. Large ribbed wheels were moved around the base by steam power, producing a pulp which was then left to ferment, with the dye itself being drained off at this time. The pulp was then rolled into balls and left in a drying shed for several weeks, by which time they had turned hard and black.

After this the balls were “taken in hand by a number of men and women, who, with an odd assortment of tools – forks, hoes, rakes, and so forth – line up in battle array and beat the balls unmercifully”. This was carried on for three days, after which the balls were turned over each day for seven days. The article continued – slow fermentation is that which is aimed at, and in the earlier stages the stench is almost unbearable to one unused to it, and it sometimes affects even the old woad-workers. At the end of the seven weeks of severe trial, the woad is reduced to a powdery substance of a dirty grey colour. It is then casked, and finally railed to the cloth markets of Yorkshire, which is the principle market for this commodity

The financial crisis of 1931 resulted in the Government declining to renew their contract and no more woad was harvested in the UK from that time.