Whiting mills

Nathanael Hodge

Summary

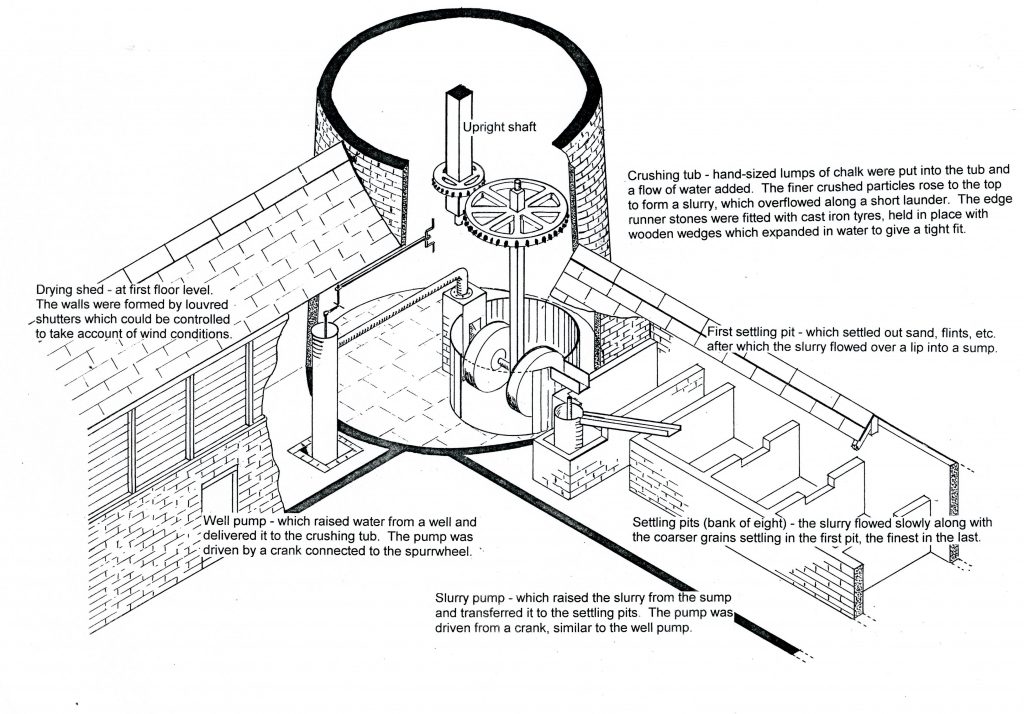

Whiting is crushed chalk, used as an ingredient for a variety of products from putty to toothpaste. Wind powered whiting mills were constructed adjacent to quarries in England in the 18th-19th centuries. Chalk was crushed in water by edge runner stones, before passing through a series of settling pits to get rid of impurities and grade the crushed chalk by particle size.

Details

Whiting is produced from crushed chalk, and has a variety of uses. It is mixed with linseed oil to make builder’s putty, added to paint to make it more opaque, and used in toothpaste and cosmetics.

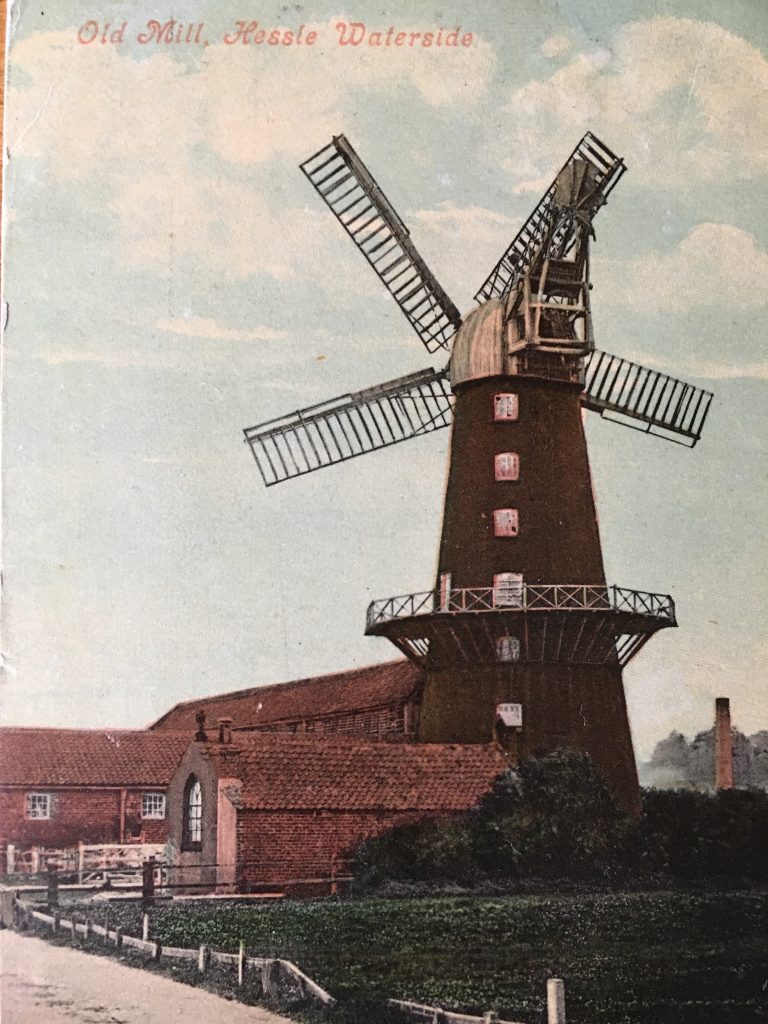

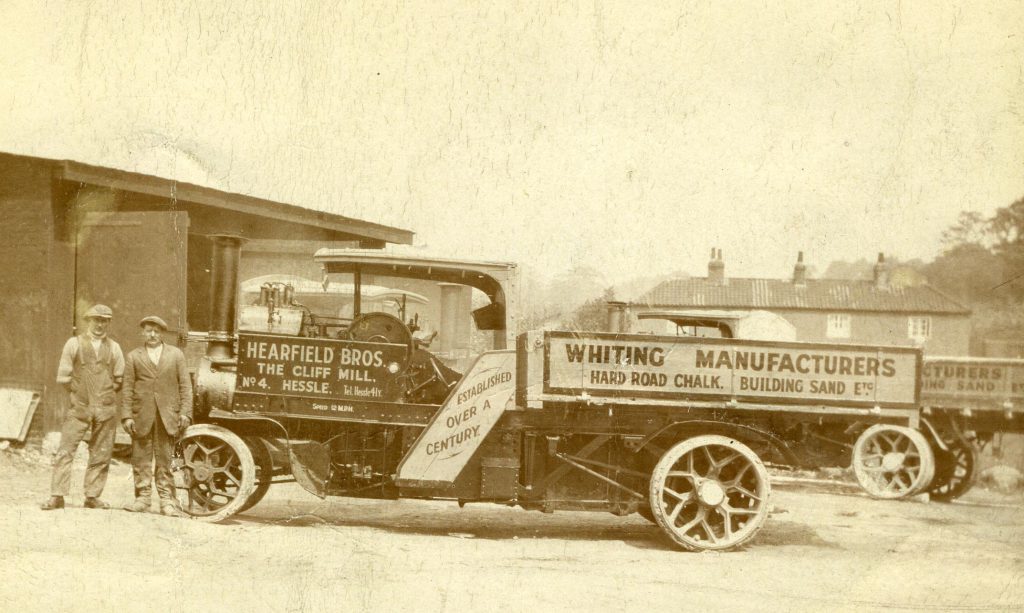

The earliest example of a wind-powered whiting mill in England is the five sailed tower mill built at Stoneferry on the River Hull, between 1775 and 1790. Ten others are listed by Roy Gregory – perhaps the most well known, which still stands today, is Cliff Mill, Hessle.

Hessle had been a site of chalk quarrying since the middle ages, and in the 18th century began producing whiting. In 1796 a horse-powered whiting mill was constructed; by 1812 a brick tower mill had taken its place.

The Hessle mill complex had a typical layout for a mill of this kind. It was built round a courtyard with the windmill tower in the north east corner. The windmill powered two edge runner stones, 5ft 1ins in diameter. These were set in a wooden tub, 8ft 6in in diameter, which was filled with water supplied by a well in the adjacent building. This is where the lumps of chalk were crushed. The edge runner stones were fitted with iron tyres held in place by wooden wedges, which expanded in the water, ensuring a tight fix.

When all the pits were full, the water would be drained and the remaining material lifted out in blocks and taken to the drying sheds, on the north and south sides of the courtyard. These buildings were fitted with shutters that could be opened or closed depending on the weather. The building on the north side of the courtyard also had a stone floor which could be heated from below for quick drying.

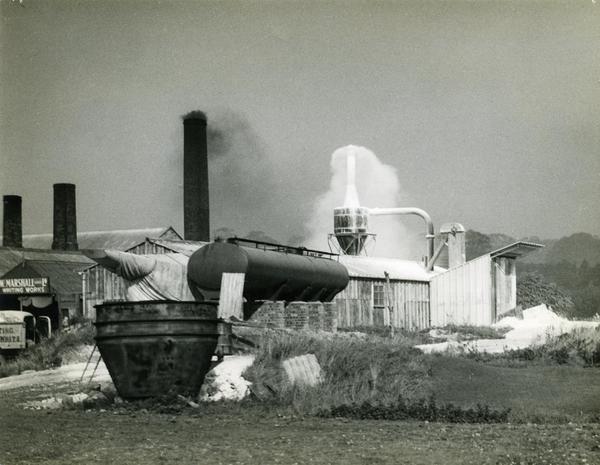

When the mill sails were removed in 1925 a larger crushing tub with larger stones was installed, powered by an electric motor. The quarry at Hessle operated until the 1960s, and the windmill tower has since been restored as a heritage attraction.

Links

Gregory, Roy, The industrial windmill in Britain (Phillimore, 2005)

Gregory, Roy, Hessle whiting mill (1984)

Images and documents in the archive catalogue