Salt mills

Mildred Cookson

Summary

There are two types of salt, sea salt and rock salt. Usually windmills or windpumps are used in sea salt production which is by the evaporation of sea water, whereas rock salt (halite) is found underground already in a solid form then mined. In the mines would be a lifting device to bring the salt to the surface, this could be a horse powered wheel or even a human treadwheel.

Details

Salt (sodium chloride) is essential for life and is one of the oldest food ingredients. Humans have processed salt since at least 6000 BC. Salt can be produced by the evaporation of sea water, or mined.

Rock salt

Rock salt (halite) can be found throughout the world, and was formed by the evaporation of salt water from seas, lakes and marshes, leaving behind salt deposits. Himalayan rock salt is mined in the Punjab region of Pakistan, and often has a pinkish tint due to mineral impurities. In Cheshire in the north west of England, salt rock deposits were formed about 220 million years ago in the Triassic period by the evaporation of salt marshes. Many of the towns in Cheshire such as Northwich, Middlewich and Nantwich take their names from the production of salt – the endings ‘wych’ or ‘wich’ referred to the saltworks.

The salt mine in Winsford was opened in 1844. The salt was extracted using explosives and shovels, and transported to the surface in wooden barrels. The work would have been difficult and the lighting poor as this relied on candles fixed to the rock – unused candles can still be found in mine. Electricity was introduced in the 1930s. The mine closed in 1892 but reopened in 1928, and is still in operation.

The salt mine at Wieliczka in Poland was established in the 13th century – at first brine welling up to the surface was collected, and later shafts were dug to extract rock salt. A Hungarian horse gear and a Saxon treadmill were used for hauling salt to the surface.

The mine is associated with the legend of Princess Kinga, a Hungarian princess who married the Prince of Krakow. Before leaving Hungary she threw her engagement ring into the shaft of a salt mine in Maramaros, and it was then discovered inside a lump of salt in the mine at Wieliczka. Kinga thus became the patron saint of salt miners.

Sea salt

Sea salt is produced by collecting sea water in ponds and allowing it to evaporate, leaving behind salt crystals. Windmills were used to pump the water from one pond to another, and also to grind the salt crystals.

In Southwold, Suffolk, seawater from the flooding of the River Blyth during high spring tides was allowed to evaporate, forming a brine. This was then pumped by wind power to the salt works, where it was dried at various temperatures in coal-fired iron pans to make salt crystals. Commercial production here ceased in 1893.

At St Monan’s, Fife salt extraction began in the reign of Queen Mary of Scots who introduced a salt tax to increase revenue to the country. The history of the salt industry of this area was recorded between 1984 and 1991 by the Royal Commission on Ancient and Historical Monuments of Scotland. A windmill, set high on a raised beach, was used for pumping seawater down channels to the salt pans. The windmill still remains today, although it has been repaired in manner different to its original design and is used as a viewing platform to view the site.

Salt has been produced in western Sicily for 3000 years, beginning with the Phoenicians. The high salinity of the Mediterranean and a climate with a lot of wind and sunshine and little rainfall makes the area highly suited to salt production. The windmills on the salt pans near Trapani and Paceco are still in use today. They have a stone tower with a conspicuous red cap, and six trapezoidal sails with cloths fastened to turn them into the wind. Some grind salt to powder, and others power Archimedes screws which transfer water from the salt pans back into the sea. In summer the salt is harvested.

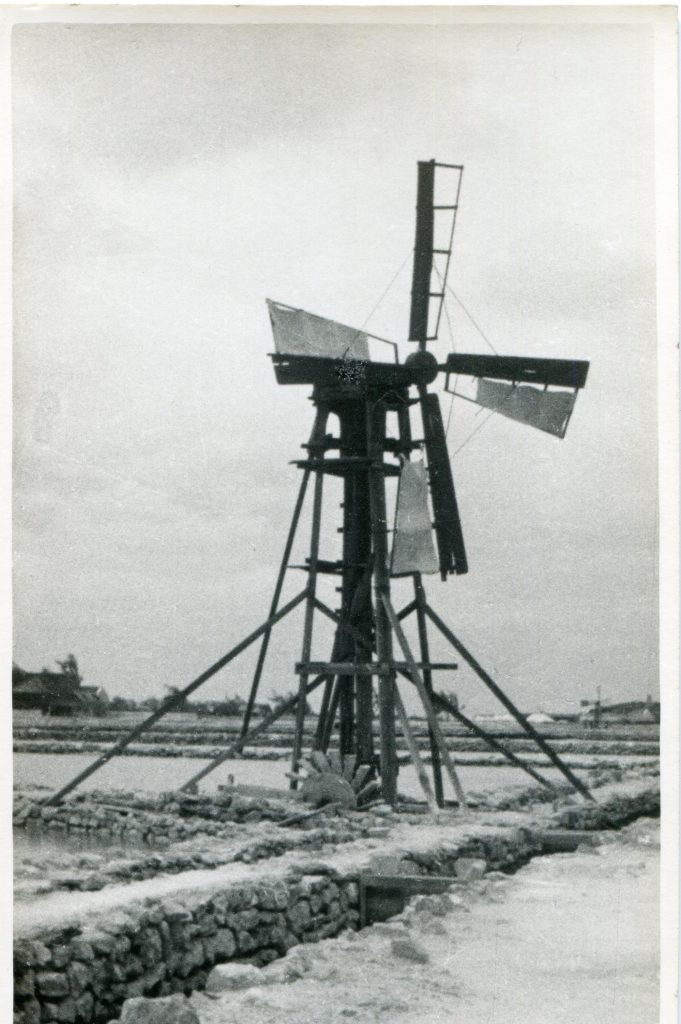

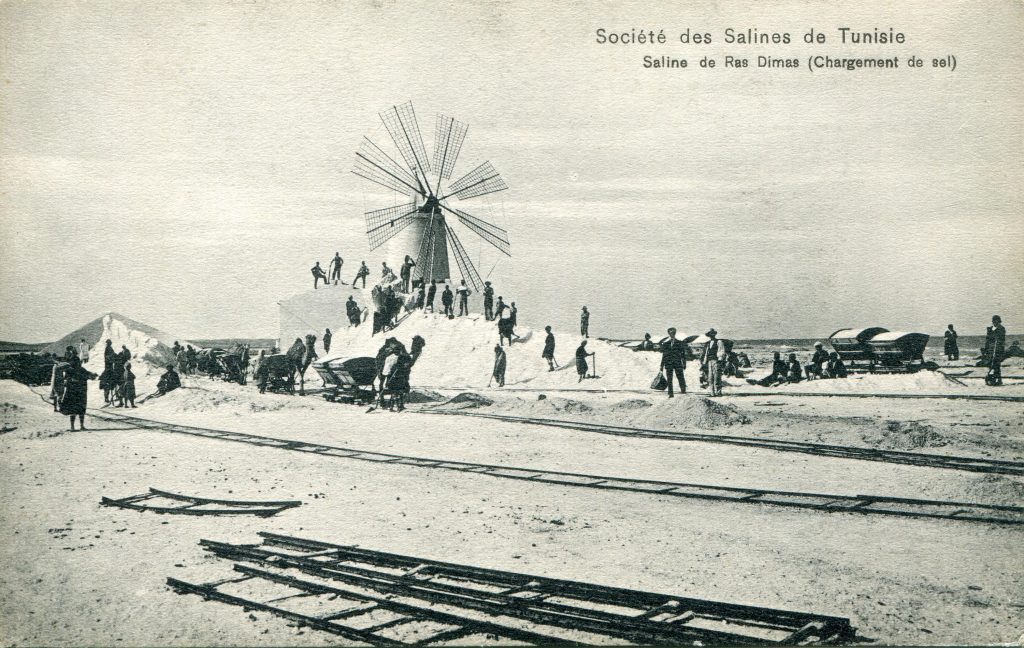

Windpumps have been used in a similar way on the Turks and Caicos Islands in the Atlantic Ocean, as well as in Tunisia

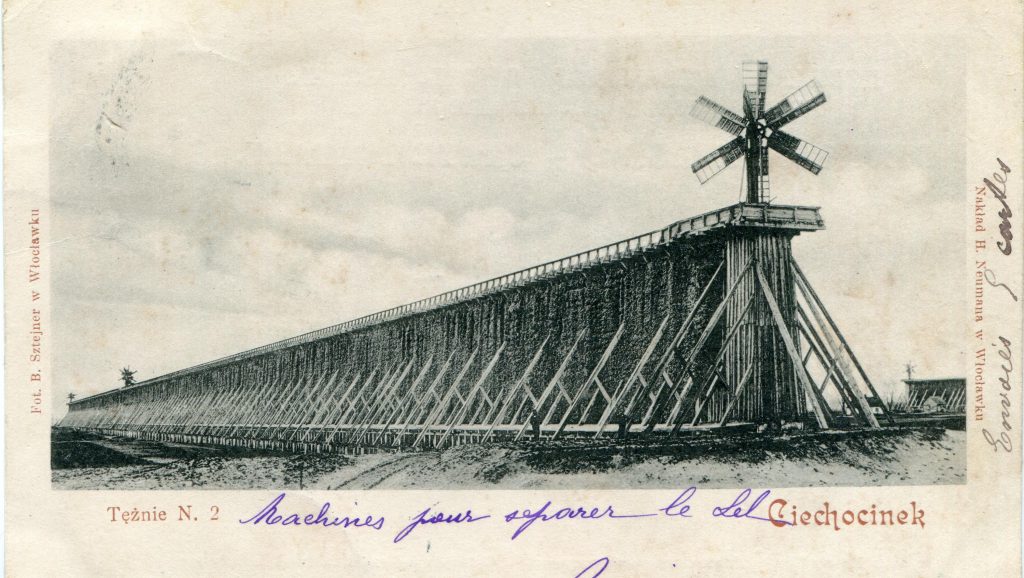

In Poland and Germany graduating towers were used to increase the salinity of brine by running it over thorny hedges. A certain amount of water would cling to the twigs and thorns of the plants. They were long, high wooden constructions with small iron windmills along the top.

Transportation

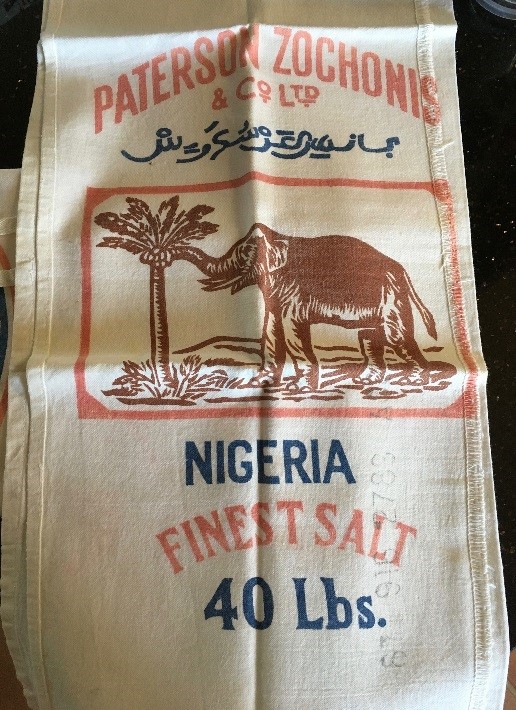

Salt was usually packed into cotton bags for transportation. In the UK the cotton mills, such as in Manchester would make the sacks for the salt companies which had emblems easily identifiable so saving the trouble of translation into different languages.

Links

List of salt mills in our database

From elsewhere on the web:

- https://www.bbc.co.uk/news/uk-scotland-edinburgh-east-fife-55485370?fbclid=IwAR3a_pwiBchvky5NBcStBwy5Si2ukaT_HsI3k9jpomt2_NZkyfOG80HAoCo

- https://en.wikipedia.org/wiki/Sea_salt

- https://en.wikipedia.org/wiki/Salt_in_Cheshire

- https://www.onlinerocksalt.co.uk/knowledge-base/salt-basics/what-is-rock-salt

- https://www.southwoldmuseum.org/industry_salt.htm

- https://italiannotes.com/sicilian-salt-mills/

- https://www.visittci.com/nature-and-history/history/salt-industry

- https://bergamotorange.net/tag/tunisian-sea-salt/

- https://en.wikipedia.org/wiki/Wieliczka_Salt_Mine

- https://www.erih.net/how-it-started/history-of-industries/salt/

- https://en.wikipedia.org/wiki/Halite

- https://en.wikipedia.org/wiki/Salt

- https://en.wikipedia.org/wiki/-wich_town