Bone mills

Mildred Cookson

Summary

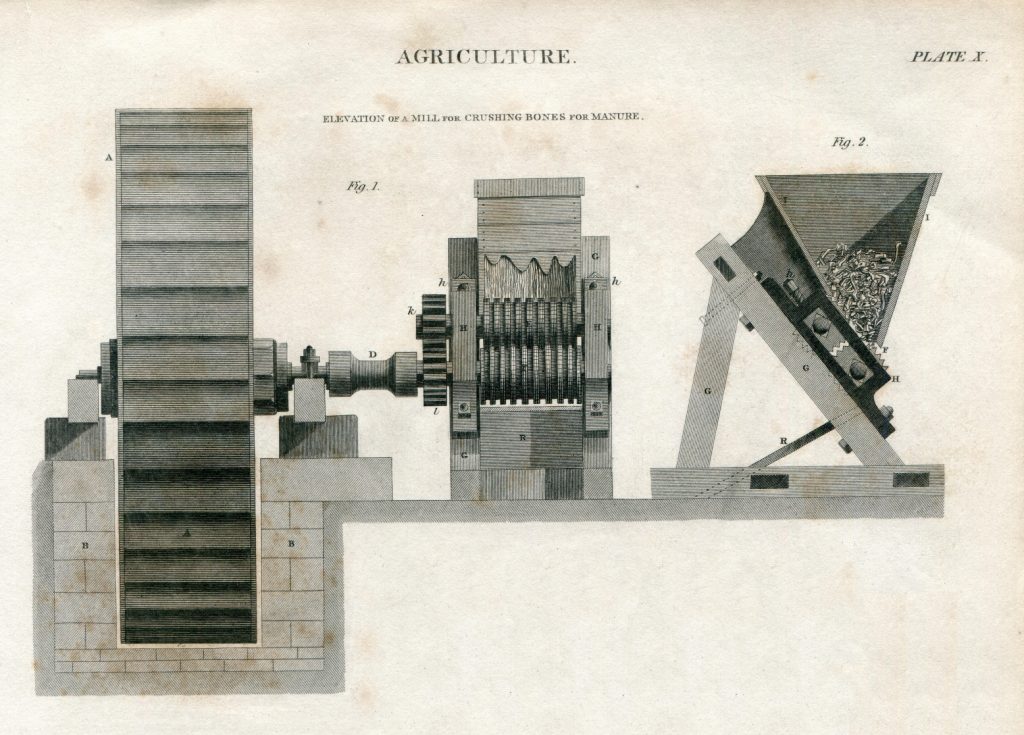

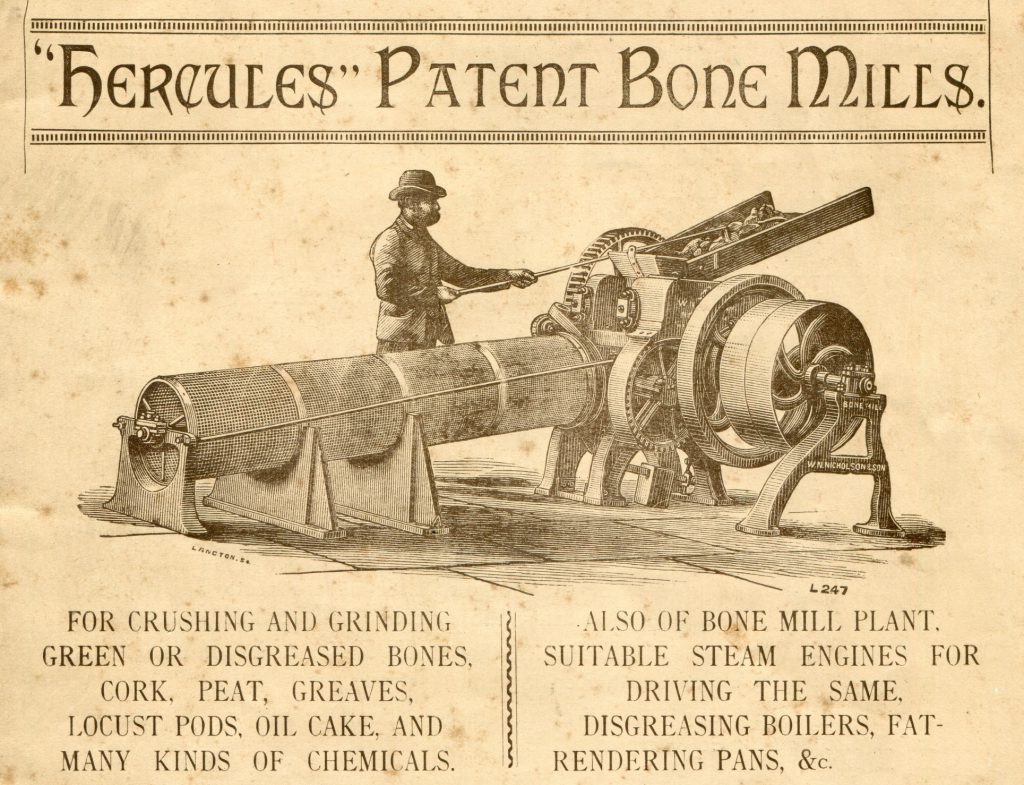

Bone mills were designed to crush animal bones either for fertiliser for farm use or for glue. Josiah Spode discovered it could be used for bone china. Bone mills were usually water powered, although windmills in the UK were also known and a paper on the bone windmills of Sweden has recently been written.

Details

The first use of bone is not recorded but it was introduced into porcelain on a manufacturing scale by Josiah Spode before 1800, probably following a long period of experimentation. Only the bones of cattle were found to be really suitable, the knuckle and shin bones being the best. Bone china typically consists of 25% china clay, 25% Cornish stone and 50% ground bone, the latter providing its characteristic translucent quality. The increasing complexity of production led to increasing sophistication and the separation of certain processes, thus the grinding of the raw materials began to be taken away from the potworks and in, some case, carried out by separate firms.

The process for grinding flint and bones is essentially the same. Bones would have been boiled first to remove tissue, this would in turn produce glue which could be sold as a by-product. The bones would then be moved to the calcining kiln where wood was used as fuel, not coal as would be used with flints, as bone is more combustible and prone to contamination from iron pyrites in coal. Calcinated bone becomes softer and whiter than in its natural state.

The calcining kiln would consist of two chambers with a hovel built above them to create a draught to aid combustion. Filling the kiln was a very skilled job requiring layering of fuel and either bone or flint. Bones would be built up in layers with wood. It would be allowed to combust for 8 to 16 hours (depending on the fuel and climatic conditions) and then left to cool before being withdrawn through draw holes at the bottom.

The kiln would be first heated up to 1000 centigrade, this softened the bones and made them easier to grind. Because of its organic nature, bone would require little fuel once combustion had commenced and could be calcined more quickly than flint.

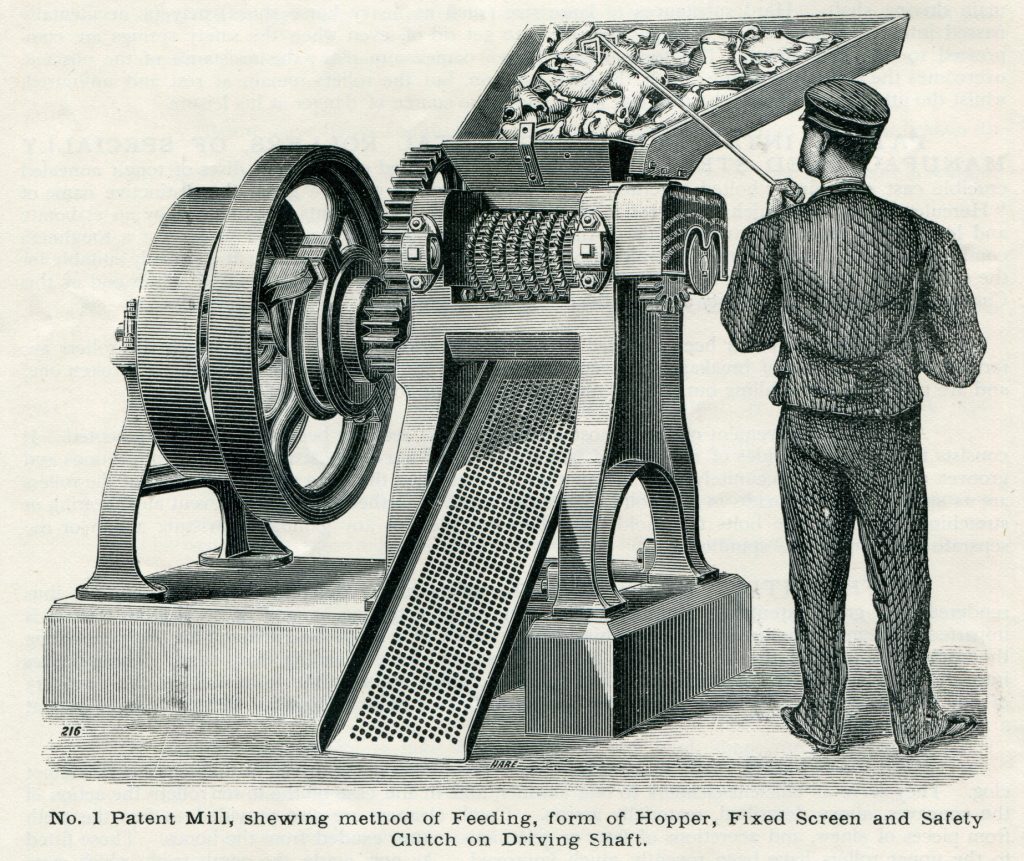

After calcining and cooking for up to at least 8 hours the bones were then cooled enough to handle and the kiln would be hand drawn from the bottom. Any impurities would be removed, and any large bones would be cracked by hammers and or passed through a jaw cracker. The material would be taken to the pan room and tipped into the pan. These would be circular of around 12 ft in diameter with vertical sides about 3ft high. The floor of the pan would be carefully built up of chert blocks on a clay seal. A vertical shaft went through the centre of the pan for the gear drive below. The shaft would normally have 4 arms which carried vertical handing timbers. After this process any fat remaining with the bone slop caused a froth and this had to be skimmed off. Following this the mixture was passed into a washtub. This would be repeated until all the sediment was at the bottom. The mixture would then be drained off so the sediment could be dried and removed in blocks.

Some millers would purchase bones ready prepared for calcining to avoid the threat of diseases such as anthrax. Many mills would boil the bones themselves with glue being a saleable by product. Local bones would have been purchased early on in the industry, but then they would be imported from India, Pakistan, Egypt and China. Cattle bones are most preferable, shin bones tend to have a high mineral content and horse bones give the ware a greenish hue. Some millers would tell stories of human bones being included in consignments and various whale and elephant bones have been saved from the grinding process. Grinding would have been done either in pans, (wet pan grinding) or with stamps raised by cams and allowed to fall under gravity onto the bones being processed (this was soon discouraged due to the dust it created, causing silicosis) or a set of edge runners or even millstones.

Although water was the usual early source of power using a waterwheel, windmills were also used. Many watermills referred to as bone mills were producing fertilizer for farms.

Whale meal

King’s Lynn relied heavily for a time on the whaling trade, a trade which brought a great deal of prosperity to the town, but which was also very risky. In 1775 the old Blubber house was built at Blubberhouse Creek. Horses towed the ships up the Nar to the site where the houses were. From here the bones were transported to Narborough bone mill where the jawbones of the whale were ground down to make fertilizer. This trade dramatically declined in 1820 and as a consequence of this the bone mill had to depend on local farms and slaughter houses for raw materials. The decline was due to the increase in gas lighting as well as competition from Hull, Grimsby and London and the abolition of the encouraging bounty.

Bone Grinding in Ireland

There was a large granite stone at Cremorgan House near Timahow used to grind the bones of the animals which were fed to the pack of hounds. The ground bone meal was then spread on the land as a source of Phosphorus. The stone was believed to have been pulled round by a horse to do the grinding. The stone measured 4ft diameter and 16 ins wide.

A similar stone which still survives is on the Stubbard Estate in Garryduff near Erill. Co Laois. According to a neighbour who lived from 1858-1939, it appeared the stone was used to make farm manure from the bones of animals.

Links

Conry, Michael, Culm Crushers: Edge runners for tempering Culm, grinding corn, bones, chalk and mortar in Ireland during the 19th and 20th Centuries (1999)