Oil mills

Mildred Cookson

Summary

An oil mill crushes or bruises oil bearing seeds such as linseed, sunflower or rapeseed, to produce oil. Oil milling was carried from pre-Roman times, and was originally carried out by human or animal power, with stamps or edge runner stones worked by horses, donkeys or other animals. Later, wind and water powered oil mills became common.

Details

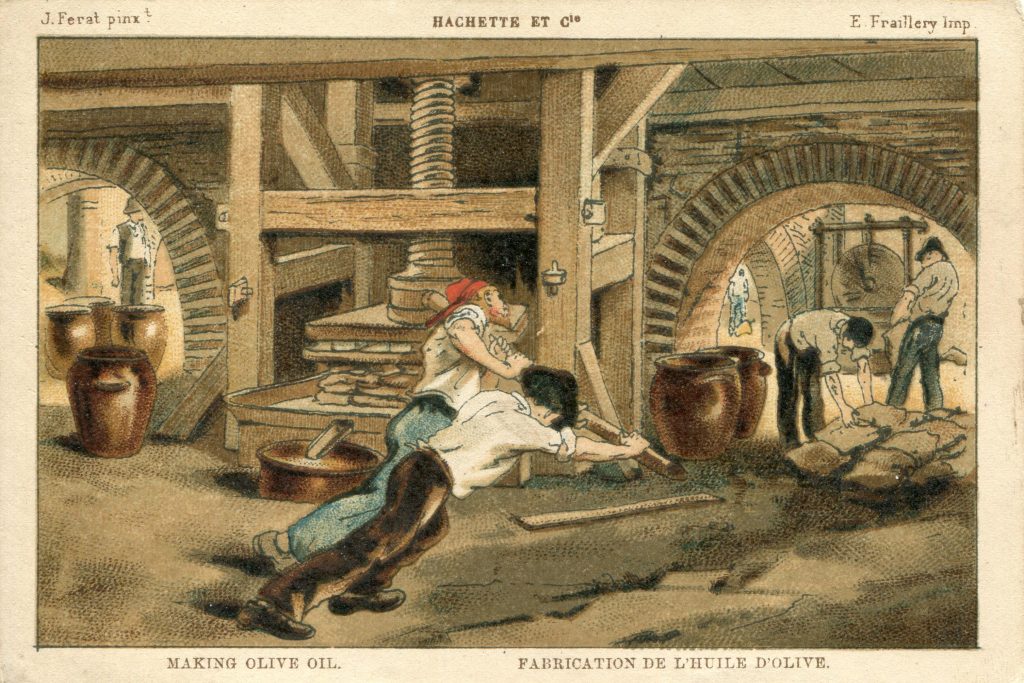

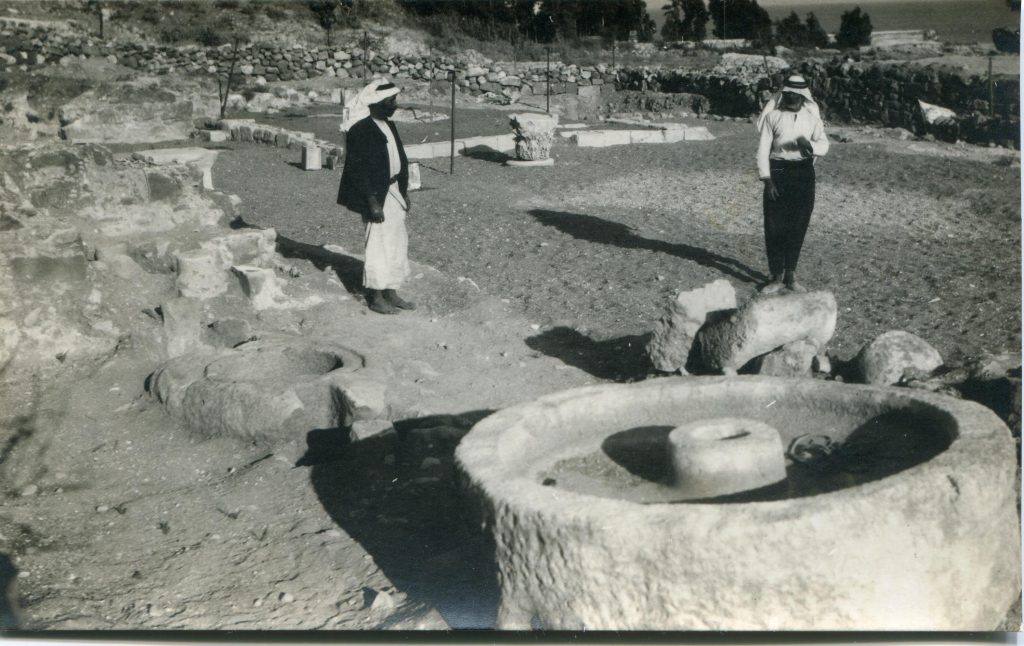

The definition of an oil mill is one that is designed to crush or bruise oil bearing seeds, such as linseed, sunflower, rapeseed, walnuts and olives. The process followed a pattern, first the crushing, then the pressing, then the separating. These processes go back to pre-Roman times, when it was done by mainly animal or human power.

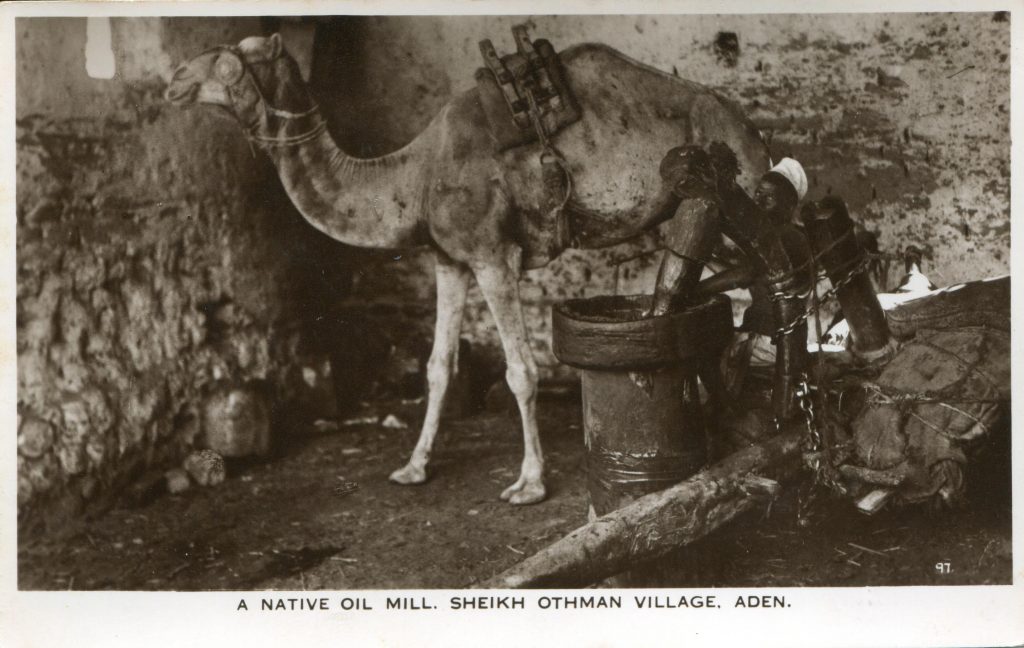

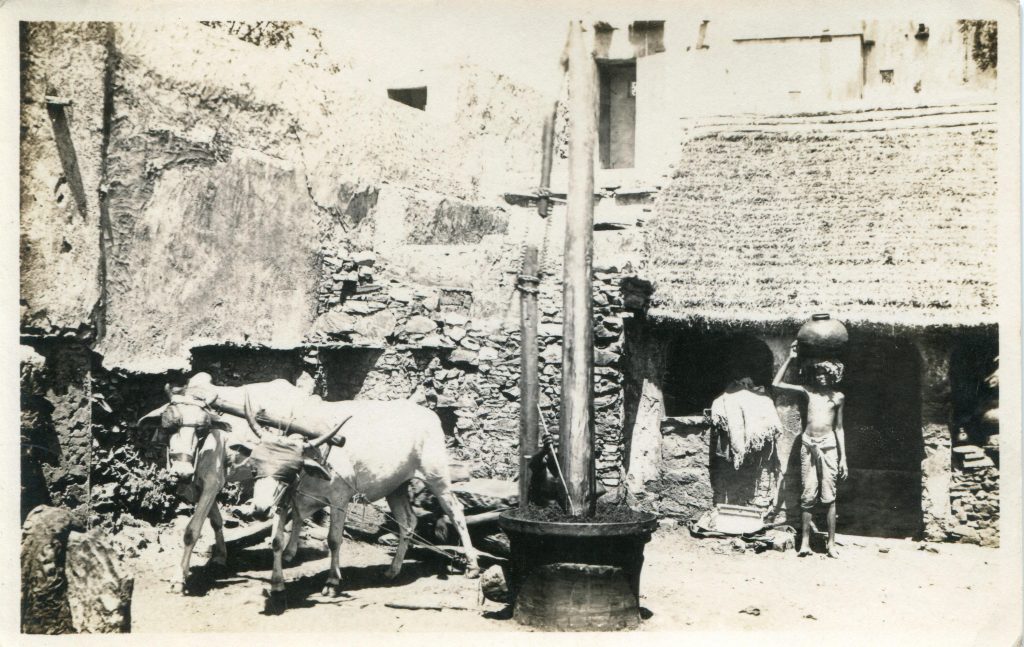

Muscle power and animal power was used throughout Europe, horses, mules and donkeys. Camels and bullocks were common in Egypt and China; in India Elephants were also used.

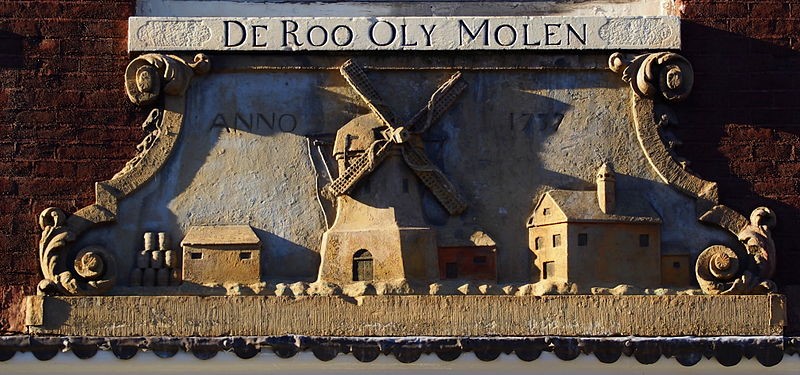

The mills usually did the crushing by stone edge runner, although in India the Ghani was used, and hand querns were also used for decortication (removal of the shell) of the safflower seed. Stamps were also used in the process of extracting the juice. Gradually over time in most countries the power of wind and water came to be used. Animal powered oil mills can still be seen at work in Southern France, but gradually more modern methods are overtaking the old ones, the same is now applying in India. In the Netherlands however oil seed crushing by windmills can still be seen at work.

Many of the olive trees still producing fruit in Europe date back to ancient times. Fields of flax, sunflowers and rapeseed all continue to be grown throughout Europe for their oil content.

In India the Ghani was the traditional way of extracting oil and goes back 2,500 years. In appearance it was in the form of a large mortar and pestle, an animal being harnessed to move the pestle, it is one of the very early methods of crushing seeds. The Romans added their contribution by using a lever and screw press.

In the UK Kingston upon Hull appeared as the centre of the oil milling trade as early as the 16th century with Rape seeds being imported. In the year 1876 there were 33 Oil and Cake Merchants in the city. John Smeaton is also known for his inventions of machinery for oil milling by wind power. His drawings of an oil windmill in Wakefield and one in Hull survive which shows their construction. There were also oil mills in other parts of the UK including London, Kent and Preston

In China, different methods of crushing were used in different regions, many were using human power, but watermills using stamps were also found.

The process seen today in the Netherlands is done with stone edge runners, powered by windmills. In other parts of Europe the stones are turned by a horse or donkey.

In America the missionary colony of the Church in Herrnhut in Germany have records going back showing their Bethlehem oil mill was for pressing linseed oil by waterpower and stamps.

In the Holy Land oil was essential for food, fuel for oil lamps and as an ingredient for soap. Here the mortar and pestle arrangement was used from early times, developing into complex screw presses. In the museum at Tel Aviv there is a working oil mill using 20th century stone edge runners, made of granite, pulled round by mule; this was still in use until the 1970’s, the process unchanged from 323 BC.

In Galilee simple cup shaped depressions were cut out of the rock at ground level and a pestle was used to crush olives. Hot water was poured onto the crushed olives and the oil would float to the top. Portable hand devices were also used, made from hard limestone. Today in the UK we grow linseed and rapeseed and even sunflowers for oil, but like most countries today these now are processed in modern mills.

Links

Nagatsune, Okura, On Oil Manufacture in the Orient (1836) – illustrated with 26 woodcuts showing three hand operated Japanese oil mills of 140 years ago

Kempers, A J Bernet, Oliemolens (Het Nederlands Openluchtmuseum, 1979)