| Jim Moher | |

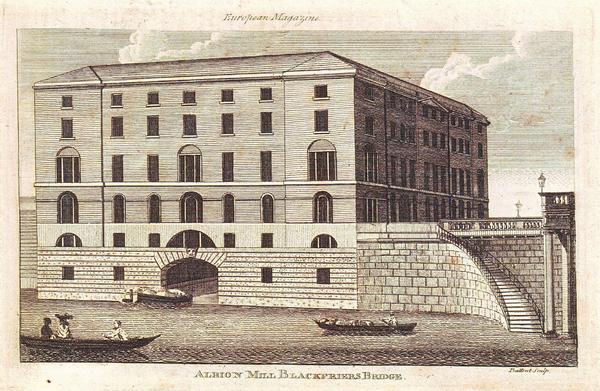

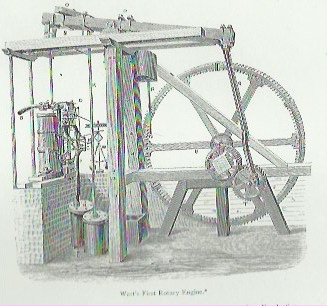

Those who have heard of the famous Scottish engineer, John Rennie (1761-1821), will probably remember him for his civil engineering achievements at the turn of the nineteenth century, such as the building of new London and Waterloo bridges. In fact, like many engineers of those days, Rennie also made considerable contributions to the development of mechanical engineering throughout Britain and Ireland. From 1784, he was responsible for devising and installing the pioneering system of iron millwork which harnessed the revolutionary Boulton & Watt ‘Sun and Planet’ rotary engines of the ill-fated Albion Flour Mills on the banks of the Thames at Blackfriars Bridge.

John Rennie, (1761-1821), millwright and engineer

(Portrait by Sir Henry Raeburn, Scottish National Portrait Gallery, 1810)

| Scotland was then the home of millwrighting; Rennie had the benefit of training with one of the leading Scottish master millwrights, Andrew Meikle (1719-1811 – inventor of the threshing machine), who practised from Rennie’s father’s farm at Phantassie, East Lothian, twenty-six miles east of Edinburgh. Uniquely, he also had the benefit of a short formal technical education at Edinburgh University. This was under the tutelage of the two leading Enlightenment scientists of his day, Professor Joseph Black (1728-1799) – Chemistry, and Professor John Robison (1739-1805) – mechanics, hydrostatics, and other Physics’ subjects. Rennie also practised as a master millwright all around the Lothians. However, this limited scale of operations soon found the budding young engineer restless for greater challenges. Fate played a hand. James Watt (1736-1819), the great improver of advanced steam engines, also a Scot and a friend of Professor Robison, was then looking for a special engineering talent to install and supervise the installation of his latest engine in London. | |

Known for its ‘Sun and Planet’ mechanism, it converted the linear motion of the engine rod into rotary motion. This worked through two medium-sized iron gear-type iron wheels, shaped to ensure smooth meshing as they transmitted the power to the engine flywheel. It revolutionized the use of steam engines for corn mills and a host of manufacturing processes whereas the early reciprocating engines could only pump water from mines in unsuitable jerky, up and down, motions.

James Watt’s ‘Sun and Planet’ gearing of his first rotary engine

(Ben Russell, Curator of Mechanical Engineering, Science Museum, James Watt – Making the World Anew (2014)

| To demonstrate these advantages, the Soho engine-makers, Boulton & Watt of Soho, Birmingham, had entered a joint venture with one Samuel Wyatt (1737-1807), a London capitalist developer and engineer. Wyatt was trying to capture a large chunk of the lucrative London metropolis and Home Counties market by building a huge six-storey Albion Mill (capital invested £106,000), at the south of Blackfriars Bridge. Robison recommended the young twenty-three-year-old Rennie, who jumped at the chance, even agreeing to take a low wage and the lesser status of foreman, to get the job over stiff competition from London millwrights. | |

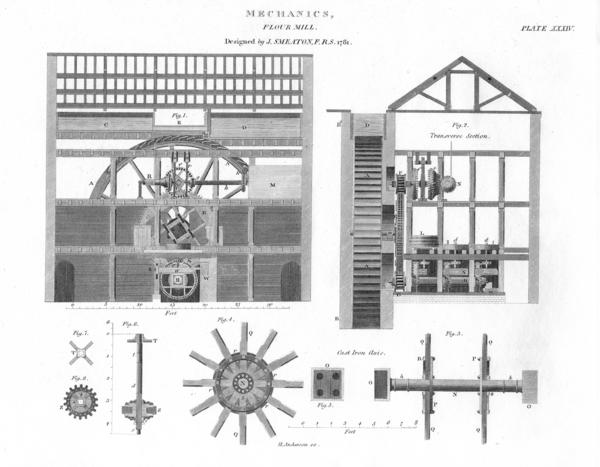

The challenge they gave Rennie was to supervise the installation of three Watt engines and devise a new system of millwork which could harness the much greater power of the new rotary engines. These (for their time) enormous 50 horse-power engines, demanded novel cast-iron millwork. Rennie brought two of his best millwrights with him, Peter Ewart and John Lithgow, (afterwards big names in the emerging engineering industry) and spent three months in the Midlands and the Black Country familiarizing himself with Watt’s engines and cast-iron machinery (Rennie’s Diary of a Journey through Northern England 1784, was published by the East Kent Maritime Trust in 1984). He took notes from Ironworks and other advanced establishments, as far north as Liverpool. These notebook sketches and detailed measurements would be his technical manuals throughout his career (few others then!). | |

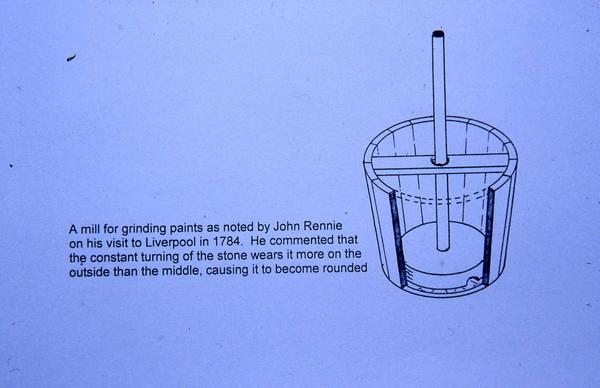

A mill for grinding paints as noted by John Rennie on his visit to Liverpool in 1784. He commented that the constant turning of the stone wears it more on the outside than the middle, causing it to become rounded.

Paint mill, Liverpool – Images and documents (millsarchive.org)

To withstand the strain of the more powerful Watt engines, they had decided that he would devise and install mostly iron millwork, departing from the traditional wood. Iron had been used as early as the 1740s in such large waterwheels as the London Bridge Waterworks and from the 1750s by John Smeaton (1724-1792), a pioneering improver of waterwheels. | |

J.G. Moher, The London Millwrights, (The Mills Archive, 2018), pp.14-15. This publication has an illustrated summary of Rennie’s involvement in the Albion Mills and the historical context of his millwrighting career. Copies are still available (£10) from the Mills Archive here.

advent

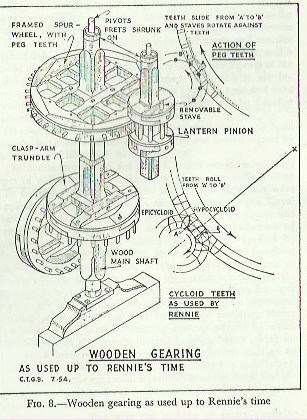

However, Rennie would be the first to systematically use iron in millwork. Here his study of mathematics and especially, his geometric understanding of curves and motion, which Professor Robison pioneered, came into play. Out went the traditional wooden gear wheels with pegs on the rims to engage the other lantern-shaped wheels of the millwork train. They were most inefficient, slipping and sliding and losing much of the power they had to transmit, through friction. Instead, Rennie devised geometric cycloid and epicycloid-shaped metal wheels, which were then chipped and filed to engage smoothly and securely.

Other innovations at the Albion Mills included having so many millstones, (twenty-six originally envisaged for the three engines), worked from a central shaft. Their layout in a continuous line was also described as ‘totally different to that in use, for corn mills driven by water’. The job of dressing so many millstones at a time, as the intense heat baked damp meal into the furrows, was another challenge, as was the laying out of much larger than traditional millstones in a continuous line.

No less than Sir William Fairbairn F.R.S. (1789-1874), gave Rennie the credit for this. Fairbairn, a millwright by training, but later a major Manchester-based engineering employer wrote a couple of volumes on Mills and Millwork. He described Rennie’s work as ‘the greatest advance in the application of gearing’. Even John Smeaton, who visited the Albion Mills, pronounced them ‘the most complete, in their arrangement and execution, which had yet been erected in any country’.

type

Rennie started at Blackfriars in 1784 and installed the first two (of three planned) engines by 1788, but he then left to set up his own millwrighting workshop and civil engineering consultancy, nearby. It had not been an easy undertaking, as his resident boss and proprietor, Samuel Wyatt, was ‘constantly interfering in matters he is by no means a judge of that it is impossible to bear it’. Rennie complained to Watt about Wyatt’s ‘overbearing disposition’, but the Birmingham partners did not intervene, seeing them both as equally to blame. Watt’s partner, Matthew Boulton (1728-1809), who was a regular visitor to the Mills, once described them as ‘a number of bulls or cocks, who stalk about for a while each swelling with his own consequence and in the end settle their respective places in a battle royal’. Watt, the stingy inventor (they only paid Rennie ‘country wages’ of a guinea a week), who was often very cranky, opined that Rennie ‘has too much forwardness and conceit’. Perhaps, but it was a very challenging job for the young Scottish millwright starting out to make a name for himself in the metropolis. | |

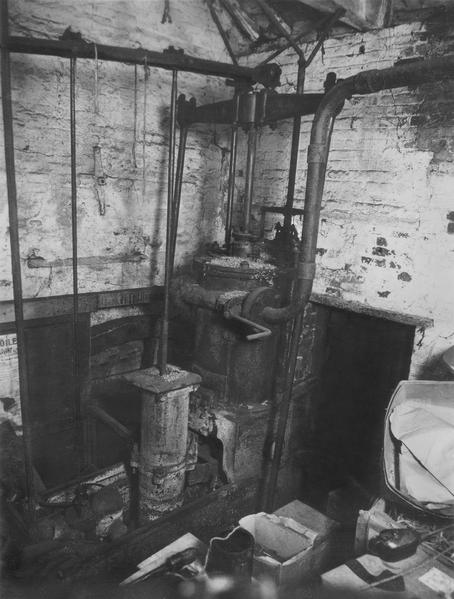

The engine in the steam mill at Upminster was manufactured by Matthew Boulton and James Watt at their Soho works in Birmingham. It was a modified Bell Crank engine rated at 6 hp and had a 10ft diameter flywheel. It drove two pairs of millstones and the drive shaft was extended into the windmill to run auxiliary machinery. This picture is thought to have been taken by Rex Wailes.

Just two engines had been erected by 1788, when Rennie left to set up his own master millwright workshop nearby in Blackfriars. John Farey, the famous author-engineer left a detailed contemporary description of the second one: ‘The engine has two fly-wheels, and two pairs of sun and planet-wheels… Each of the axes of these two sun-wheels and fly-wheels gave motion to a separate flour-mill, containing 5 pairs of mill-stones…’ A print showing the whole set-up was included by Professor Robison in his Encylopedia Brittanica articles from 1797.

Boulton and Watt engine in the steam mill at Upminster – Images and documents (millsarchive.org)

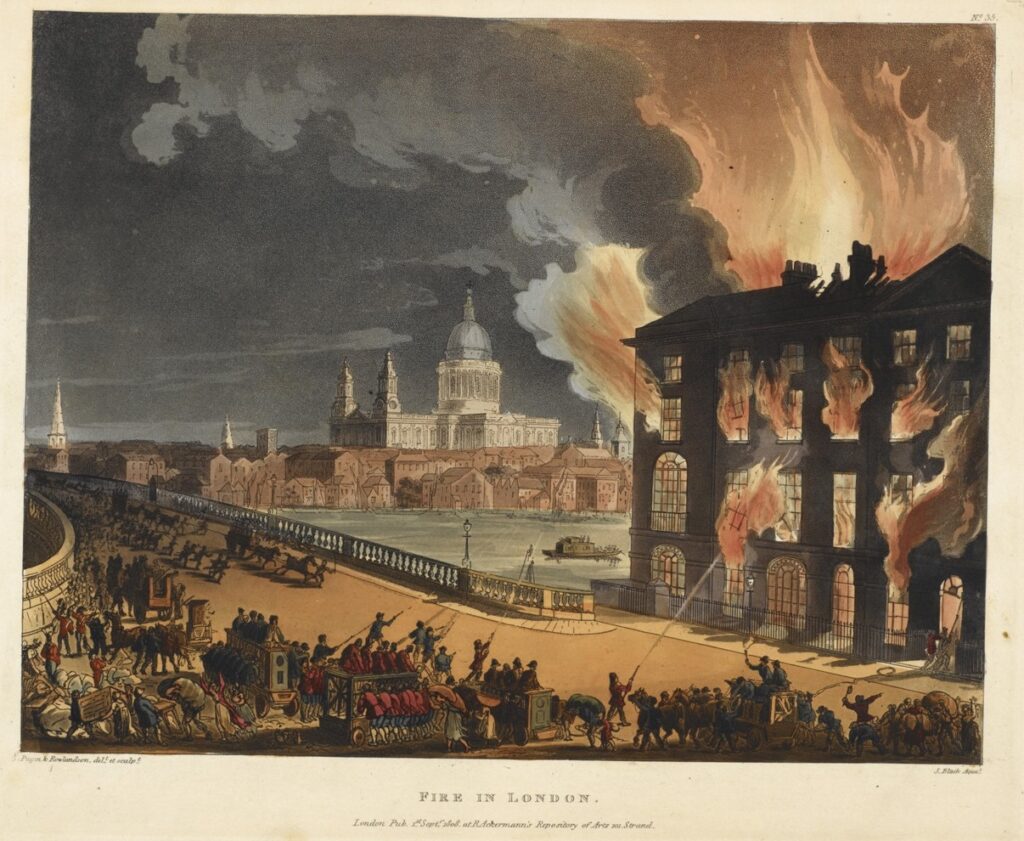

Whatever these internal squabbles, they were nothing as compared with the fierce hostility with which the entire project was received in London. The huge six-storey mill on the Thames, the first of its kind, was viewed with a mixture of fear and trepidation by the traditional small and medium-sized millers and merchants (five hundred or so, especially of Berkshire and Essex), who could not hope to compete once the colossus got going. The London populace generally, despite the cheaper bread prices it promised, were also not supportive of this giant monopoly enterprise and succumbed to the milling interest propaganda. Indicative of this mood was that of William Blake, who lived near the Mills at Lambeth and walked past regularly. He is thought to have had it in mind for his ‘Satanic Mills’ of Jerusalem. One night in March 1791, the Mills took fire causing a massive conflagration on the Thames to the great exultation of the traditional millers, merchants and we suspect, traditional millwrights. It was even noticed in the leading journal of record of the time, The Annual Register on March 3rd. Arson was suspected, though Rennie thought it more likely to have been caused by a spark from the machinery. This gives a flavour of the times and the resistance to all such innovation by vested interests. However, the Albion Mills achieved its purpose for Boulton and Watt as their engines began to replace the horses in most of the major breweries, distilleries, and other large manufactories from that time onwards. As their agent throughout the 1790s, Rennie was involved in many of these conversions, with his innovative iron millwork accompanying them. His millwrights’/engineers’ workshop at Blackfriars continued to develop this and other contracts all over the metropolis and surrounding counties until his death in 1821. Cyril Boucher’s John Rennie, 1761-1821: The Life and Work of a Great Engineer (Manchester University Press, 1963), has a chronological list of his subject’s mainly civil engineering achievements, which takes up fourteen pages (123-137). Rennie’s mechanical works in the 1780s and 1790s in the London breweries, distilleries, and other manufactures are also very numerous. Moher’s The London Millwrights and Engineers 1775-1825, p. 167, has a list of 18 major jobs from 1784-90. His sons, George and John, were both trained there, and George continued the mechanical engineering side of the firm far into the nineteenth century. John went more into civil engineering and took over from his father in the completion of the new London Bridge in 1831. John junior wrote a Life of his father in 1870, recalling the elder’s Albion Mills achievements. The unpublished but most informative manuscript is in the library of the Institution of Engineers, London. | |