| In the last few months this newsletter has featured several articles about the Montefiore Windmill in Jerusalem, which was built by the firm Holman Brothers of Canterbury. This newsletter delves deeper into the history of the firm. | |

| Holman Brothers was a Canterbury firm founded in 1816 by John Holman. Originally millwrights, they built smock mills in Kent as well as repairing other wind and water mills, and building two tower mills in the Middle East at Jerusalem and Haifa. Later as the demand for mills declined, they also entered the agricultural machinery business, hiring steam ploughs and threshing machines to local farmers. | |

The origins of the firm

| John Holman (1783-1855) was the founder of the family firm. The youngest son of William Holman, miller at Boughton under Blean, he went to sea before becoming an apprentice millwright with the firm Sweetloves of Wingham in 1806. In 1816 he bought an existing business in Canterbury, eventually being joined by his sons John James and Thomas Richard Holman who took on the business after his death. | |

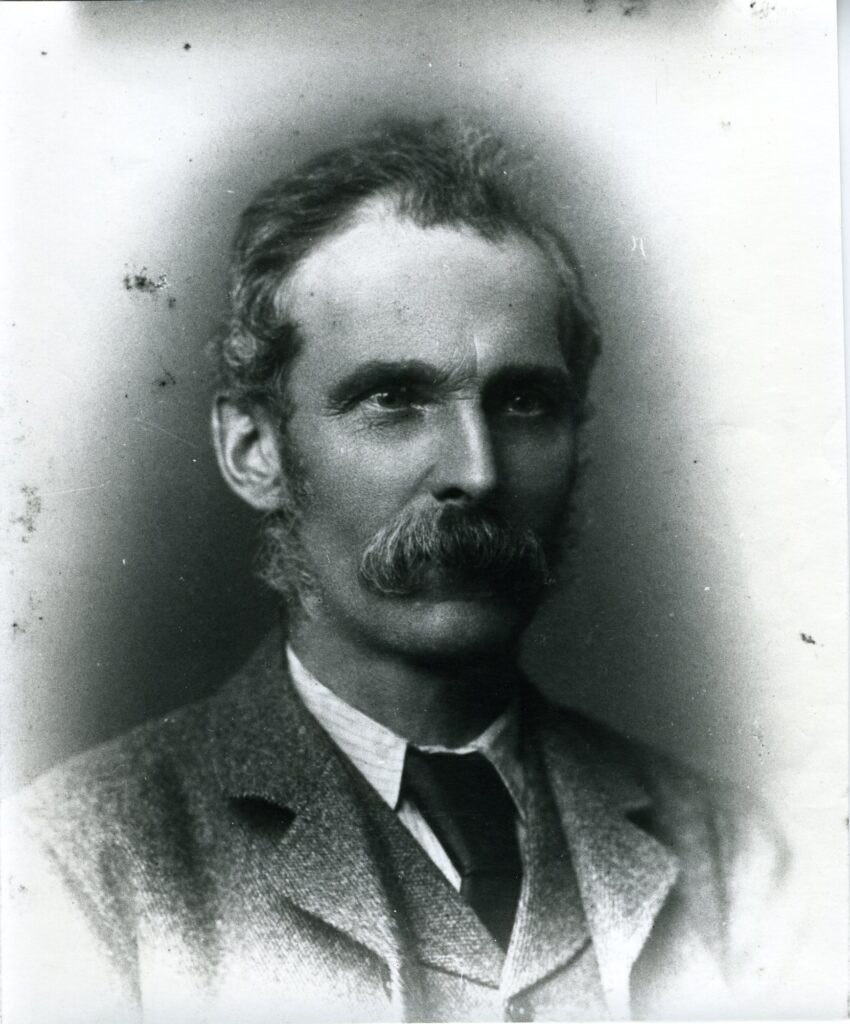

| After his older brother John James’ death at the age of 40, Thomas Richard Holman (1831-1897) carried on the business, at first in partnership with John James’ widow Catherine, and then with Albert Collard until 1885, when Thomas Richard became the sole director. | |

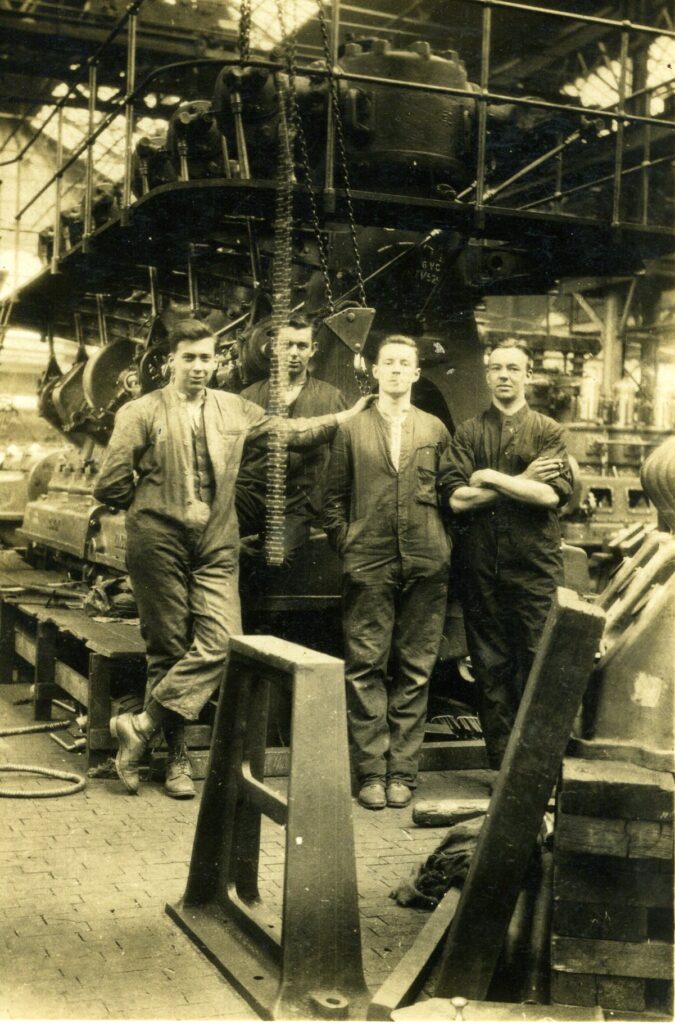

| This is one of the oldest photographs in the collection, dating from the 1870s. It is a tintype, an early form of photography using a sheet of iron rather than paper. It shows T R Holman surrounded by his employees. The two boys on his right and left may be his sons, Harry Branford and William John. In 1857 T R Holman was hired by the banker and philanthropist Sir Moses Montefiore to construct the windmill in Jerusalem. The Holmans were later commissioned to provide machinery for a mill in Haifa, Syria (now in Israel). Unfortunately, on this occasion an important part of the machinery was lost in the sea while being unloaded at Jaffa. | |

HOLM-04-HB116)

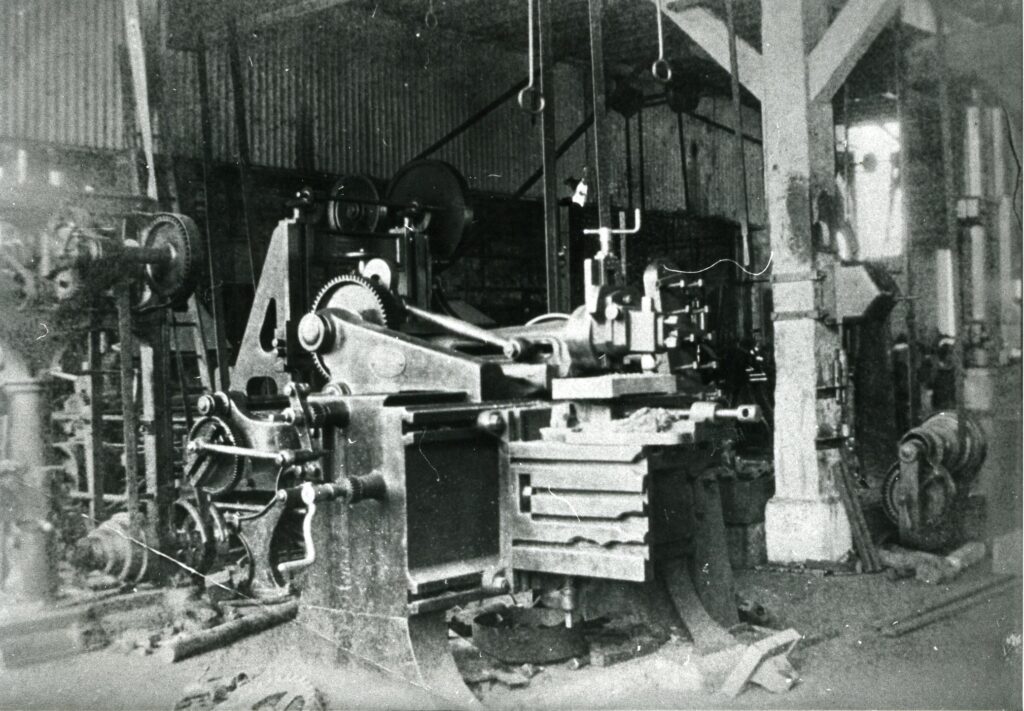

| Most of the work of the firm was carried out at the workshops at Dover Street, Canterbury with hand-operated machinery, both for manufacturing and repairing wagons and ploughs as well as millwrighting. With the advances in mechanisation on the farms, the workshops were gradually updated by adding various power-driven metal working machinery including lathes, grinders, drilling machines, grindstones, power hacksaws and a power hammer. These were eventually driven from a layshaft driven by an engine in a newly constructed engine and boiler room. | |

| The engineers would be called upon to manufacture and repair all manner of things. When steam engines became the source of power on farms the Holmans were involved in making and repairing pistons, fire boxes and bars, and valves for pumps. They were employed to repair engines for Sturry Fire Brigade, printing machinery for the Kent Herald newspaper, a sausage machine for a Mr Craig of Burgate and even, in 1877, sawing out gun stocks for a local gunsmith. Folkestone Cliff Railway, marmalade machines, oast house fans, and a railway track for City Corporation in 1884 were also repaired. In 1877 the Right Hon. Lord Sondes employed them to strengthen a lime tree at the Kent cricket ground, unique as it was the only one in England growing inside the boundary line. | |

The Holman mills

(Mills Archive Collection, HOLM-04-HB152)

The Holmans built only wooden smock mills in Kent. When they were built, timber was much cheaper than brick and as there was little local stone being quarried, fewer tower and more smock mills were built. A lot of pine was being imported from the Baltic for building warehouses and this was used as a source for wood, in addition to that locally grown. Baltic pine was slow growing and had a high resin content which helped it withstand the elements. It was imported through the ports of Dover and Folkestone which were both easily accessible from Canterbury.

Stelling Mill, built by Thomas Holman for George Goble in 1866, on the site of a former post mill. Shown here in 1937.

(Mills Archiv Collection,

HOLM-04-HB196)

Paragraph

Much of the work in building a mill would be carried out in the works by a number of men. The actual erection would be carried out by two or three men with occasional extra hands for some of the heavier lifts. It must have been quite an undertaking as all the lifting of the comparatively heavy gear to the top of the mill had to be done with poles, shear legs and blocks and tackle as cranes were not yet in use. The carriage of tackle to the site would have been done with wagons drawn by horses. Hours were long, 6am to 5.30pm with half an hour for breakfast and an hour for lunch. When working on complex repairs to mills which took several days or weeks, it was usual for the millwrights to lodge with the miller. Harry Branford was doing this on 18 January 1881 when there was a snowstorm which left him snowbound and isolated for more than a week.

The last Holman mill to be built, St Margaret’s Bay Mill, Kent was built in 1928-1829 to generate electricity.

(Mills Archive Collection,

REXW-IMG-02-042)

| There are also many records of millwrighting work on both wind and watermills in the area of east Kent, and also at mills further away such as Delce Mill at Rochester, Vale Mill on Guernsey for Mr Hucart, Coleshill Mill at Amersham, and Sutton Valence Mill for Sir Edmund Filmer. The Holmans’ records show work done to more than 120 mills within 20 miles of Canterbury and there were doubtless other millwrights doing work at other mills which do not figure in the firm’s records. For details on each of the mills built by the Holmans, see the website: https://new.millsarchive.org/2015/03/10/holman-bros-millwrights-of-canterbury-a-history/8/ |

Holman Brothers

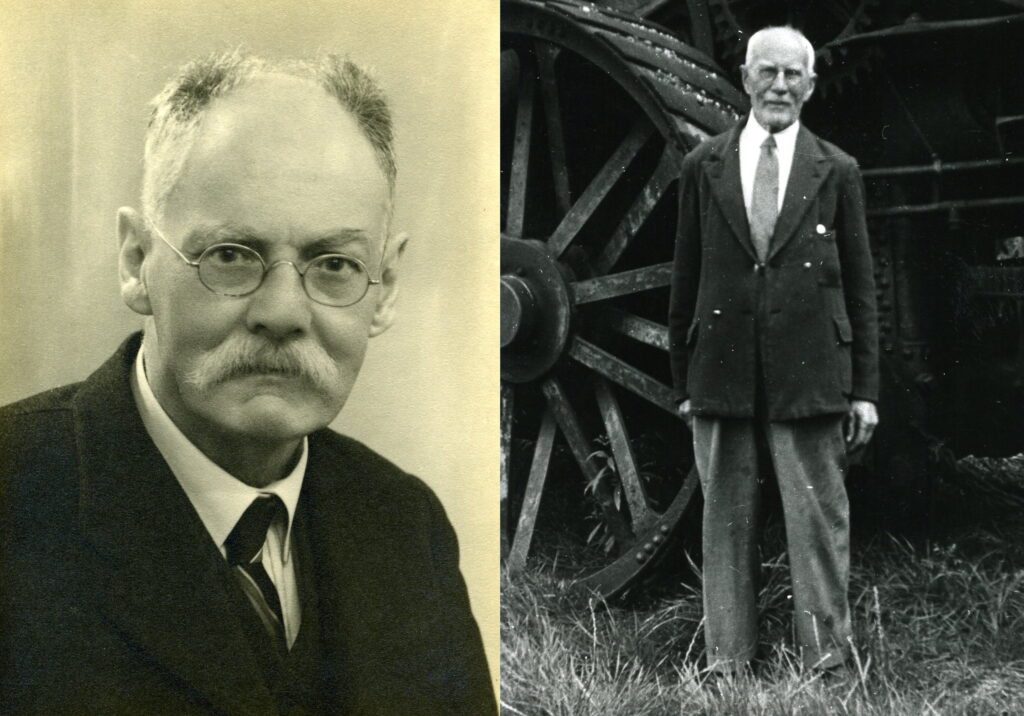

| Harry Branford Holman joined his father’s business as an apprentice millwright in 1880 at the age of 17, and his brother William joined the following year. After their father’s death in 1897 they took on the business which became ‘Holman Bros, engineers and millwrights’. The character of the firm was gradually changing as wind power was being replaced by engine power. Many mills had steam or combustion engines installed to keep the mill turning during periods of little wind. |

HOLM-04-HB012)

| At first the firm only sold goods associated with windmills, including weighing machines, sack barrows, mill bills, replacement parts for the mill and machinery such as dressing machines and additional millstones. As the firm widened its scope to agricultural engineering, sales took on a new dimension with many additional lines being added. At the time Harry joined the business in 1880, practically the only implements in use on the farms were Kent ploughs and wood harrows, both of which were made by the firm. In 1895 the firm became agents for Ransomes, Sims & Jefferies, one of the leading manufacturers of agricultural machinery. A limited range of farm machinery was on display in the yard behind the office, including hay rakes, mowers and tractors, but much was made to order with items being delivered directly to the customer. |

HOLM-04-HB082)

Records show a wide diversity of machinery being sold, including bottle washing and labelling equipment, chimney sweeping, soda water making and lime grinding machines. In 1901 the firm started exhibiting at the East Kent Agricultural Society’s Ramsgate show, where they had two stands: one showed machinery in motion, the first of its kind, and the other an uncovered space for general exhibits. For many years they had a stand at the Kent County Show which was formed when the East Kent and West Kent Societies merged. Their other sales stand was at the Canterbury Cattle Market each week when one of the Holmans attended to meet and sell to farmers. |

The last generation

HOLM-04-HB034)

| 1920 saw Harry’s son, Frank, join the firm aged 17 and in 1931, Thomas Richard (Tom) joined the firm having served an apprenticeship with Ruston and Hornsby of Lincoln building horizontal and vertical crude oil engines. William’s son John Angell (Jack) joined the firm for a year in 1937 before being called up for the war. He returned afterwards for three years before leaving again, but continued to have a holding interest in the business. On 21 November 1949, a new company ‘Holman Bros., (Canterbury) Ltd’ was formed – the management remained unchanged. The bracketed Canterbury was to distinguish the firm from the Holman Bros. in Cambourne, Cornwall who were also engineers, but were involved with mining equipment. Even with this in the address both firms frequently had to forward wrongly-delivered mail. | |

(Mills Archive Collection, HOLM-04-HB009)

| On 5 December 1968 Holman Bros., (Canterbury) Ltd. went into liquidation because Frank and Jack had decided to retire from the business. Half of the Company was owned by Jack, and the other half split equally between Frank and Tom. In order to pay their share, and for Tom to carry on, the Dover Street premises were sold and the business moved to the Old Dover Road site. The firm closed down in 1975 due to the compulsory purchase of the Old Dover Road yard by the City Council to build the approach to a new car park. Tom felt that, at his age, he could not move the business elsewhere. The site was sold to the Council at a modest price because they determined it could not be used for residential development. The final auction sale of fixtures, fittings and stock took place on the 3 April 1975, marking the end of over 150 years of continuous trading. The planned car park scheme never materialised, and the Council eventually sold the site to developers who built the present Holman’s Mews apartment complex. | |

The collection can be viewed on our catalogue: https://catalogue.millsarchive.org/geoff-holman-collection. Geoff was working on a book on the firm’s history, and with support from the family we completed his work. The information in this newsletter is summarised from this source; you can read the full account on our website: https://new.millsarchive.org/2015/03/10/holman-bros-millwrights-of-canterbury-a-history/.v

The collection can be viewed on our catalogue: https://catalogue.millsarchive.org/geoff-holman-collection. Geoff was working on a book on the firm’s history, and with support from the family we completed his work. The information in this newsletter is summarised from this source; you can read the full account on our website: https://new.millsarchive.org/2015/03/10/holman-bros-millwrights-of-canterbury-a-history/.

Geoff Holman (1937-2011)