Digital conversion era ahead for our industry

Full details

| Authors & editors | |

| Publisher | Milling & Grain |

| Year of publication | 2021 January |

| Languages | |

| Medium | Digital |

| Edition | 1 |

| Topics | Energy & power > Development of technology |

| Tags | |

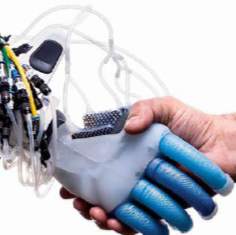

| Scope & content | Peter Marriott, Sales Manager, Henry Simon UK looks forward to a future of digital development that goes beyond Industry 4.0 where ‘big data’ and ‘The Internet of Things’ provide more light-out manufacturing in the grain and milling industries. Industry 4.0 was first announced in 2011. The Hannover Exhibition in Germany and until now has brought serious changes to industry. After the historical development steps of mechanisation, mass production and automation, today the new era has focused on higher productivity with digitalisation in industrial processes. The industrial development had been almost singularly driven by web-based technologies in recent years. And within the digital conversion, we started to hear about new technological terms like ‘big data’, IoT, cyber security, machine learning and artificial intelligence, etc. These terms are actually the fundamentals of a new generation of industrial systems. In this article, I hope to explain how we can benefit from them in industrial applications, by focusing on their definitions, principles and examples. Internet of Things (IoT) IoT network basically connects the physical world’s objects to each other in the web environment. Today approximately six billion devices are connected to the web, whereas it is expected to raise up to 22 billion soon – with 5G technology. IoT is expected to allow machines, systems and even plants to connect and communicate with each other for an integrated process management. The new generation of controlled irrigation systems is an interesting example of IoT, with automated operation and process optimisation in agriculture. These systems carry out the irrigation process with real-time monitoring of the soil humidity by inground sensors. Moreover, these devices can receive the weather forecasts by wireless network connection and then schedule the irrigation periods accordingly. Data Engineering Today, many industrial devices are able to record their operating and processing data. This raw data stack can actually be analysed further to get a piece of meaningful information using data engineering methods. This gives us important tips to improve our processes and develop new systems such as: data collection; data analysis; modelling; machine learning and decision making systems with AI. As the principles of data engineering are described above, they will provide a real insight for us to develop the artificial operating systems of the future. Machine learning Machine learning is a category of algorithms that allows software applications to become more accurate in predicting outcomes, without being explicitly programmed. In other words, new generation machines will able to make predictions based on the learned data, to optimise their operating conditions themselves. Machine learning algorithms are the basics of new programming methods in industry, which are expected to bring a higher self-managing ability for machines and systems. As an example, silo systems are used to store grains under optimum conditions. Today, temperature and humidity values can be measured in silos to sustain the optimum storage environment. Imagine if they could learn to adapt themselves according to the changing ambient conditions? Machine learning examples can be extended for a very wide range of applications in all industries. Read more... |