| From Quern to Computer; a history of flour milling by Martin and Sue Watts covers a wide range of topics and Chapter 14 is particularly interesting. | |

| The importance of bread in the early medieval period is highlighted by the Old English words for lord (hlaford) and lady (hloefdige), meaning loaf keeper and loaf kneader respectively. Payments and rents were often made in loaves. As in Roman times bread from fine white flour was considered the best and on feast days spiced bread or cakes were made. Bread was considered a strengthening food and medical books contained recipes using fine flour for those patients with delicate stomachs. There seem to have been two basic sizes of loaf, large and small. Bread was usually eaten with butter or dripping or something more substantial such as cheese, beans or meat. The story of King Alfred burning the cakes is well known and although it is only a tale written to illustrate his desperate plight after his defeat by the Danes at Chippenham in AD878, it nevertheless illustrates that in many households bread would have continued to be baked on the hearth. However, ovens are also known, mostly associated with monastic and wealthier establishments such as at North Elmham in Norfolk, Goltho in Lincolnshire and Portchester, Hampshire. | |

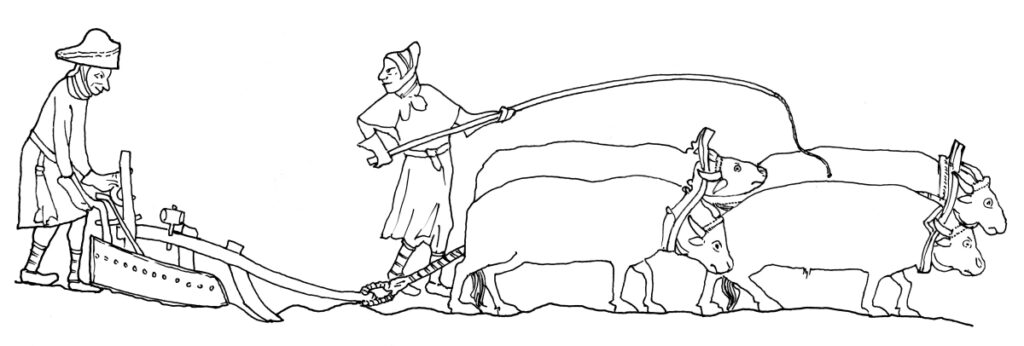

| Bread continued to be a staple food throughout the Middle Ages. In rural areas most households baked their own bread. This was probably usually under a pot on a hearthstone but some small rural cottages, such those excavated at Hangleton on the Sussex Downs and Tresmorn in north Cornwall, had their own ovens. The floor of the oven in the cottage at Tresmorn was a granite rotary quernstone – a not uncommon reuse. Monasteries, castles and manor houses also had their own bakehouses and ovens. In towns and cities, however, commercial bakers were gradually increasing in number; there were at least six operating in Winchester by about 1100. Like millers, bakers appear generally to have had a bad reputation. This was perhaps not undeserved for in 1266 an Assize of Bread was decreed by royal order. This standardised the weights and prices of bread and grain and was intended to stop or at least reduce the practice of selling under-weight bread, and to keep prices down and curb undercutting and racketeering between the bakers’ guilds. A number of medieval manuscripts depict baking, showing scenes such as kneading the dough in a trough and taking small round loaves from the oven with a wooden peel. Similarly, the production of small white loaves is depicted in the series of illustrations from the Ordinances of the York Baker’s Company, 1598, and an oven, kneading trough and peel are also featured amongst the bakers’ tools in Randle Hoolme’s Academy of Armory, 1688. Indeed, the method of baking bread in wood-fired domed clay ovens was to remain virtually unchanged until the introduction of steam ovens in the 19th century. As in earlier periods, there were several different types of bread. Pandemain was the finest, made from wheat flour sifted two or three times; loaves of white bread are shown on the table at which the family and guests are being served a meal in one of the scenes of everyday life depicted in the 14th century Luttrell Psalter. At the other end of the scale was maslin, a mixture of wheat and rye, and horse bread which included peasemeal and ground beans. The carbonised remains of small round loaves which had been made from a mixture of wheat and rye were found during the excavation of a house in Ipswich which was destroyed by fire in the 11th century. Tourte or brown bread, wholemeal mixed with rye or barley flour, was used for trenchers (from the Norman French tranchoire, meaning slice) at wealthy tables, used to soak up the gravy and juices from pieces of meat. The trenchers were not usually eaten as part of the meal but given to servants, dogs and the poor at the gates afterwards. Gerald of Wales in his Description of Wales, written about 1188 says that ‘sometimes they (the Welsh) serve the main dish on bread, rolled out large and thin, and baked fresh each day’. Monastic accounts indicate that different grades of white and brown bread were produced in the abbey bake-houses; the best quality for the abbot and his guests, the poorest quality for the abbey servants. | |

| Breadcrumbs were used for thickening sauces and there were also spiced and honey-sweetened breads. Otherwise, grain was used, as it always had been, in pottages, broths and porridge. In the north, west and south-west barley bread and oat cakes were more common fare, cooked on a griddle or bakestone. During excavations of a medieval settlement at Beere near North Tawton, Devon, a griddle plate was found close to the hearth in one of the cottages. Barley was also particularly used for malting for brewing although other types of grain including oats were also used. Matthew Paris, a monk of St. Albans Abbey in Hertfordshire in the 13th century, records how the abbot improved their rather weak beer by putting aside ‘about a thousand loads of corn suitable for making beer’. This he says was a mixture of oats and barley, called bresia. Ale or beer (hops were used in the brewing process from at least the 8th century) was drunk on a daily basis by men, women and children, being was safer than water. Most brewing was done by women. Many households brewed their own, as did each tavern and alehouse but there were also commercial breweries. The presence of ovens and large quantities of germinated barley found within a 13th century building excavated in Alms Lane, Norwich and other features included a pit in which the barley was soaked, a malting floor and fragments of imported lava querns for grinding the malted grain, suggest that this was one such site. Manor houses, abbeys and castles also had their own brew houses. The malthouse at Fountains Abbey, North Yorkshire had a kiln at one end of the building and a circular steeping pit at the other large enough to make some 2160 gallons (9819 litres) of ale at time. To put this in perspective, manorial and abbey accounts suggest that occupants were allocated on average about a gallon of ale a day. It is perhaps, therefore, not surprising to read that the monks of Westminster Abbey consumed some 80,000 gallons (363,687 litres) of ale a year. Such consumption placed considerable demand upon agricultural resources; an acre of land would have been capable of producing sufficient barley for about 140 gallons (636 litres). | |

| Although there are plentiful documentary references to watermills and windmills grinding malt in the medieval and post-medieval periods, references to malt mills in household inventories of the 16th, 17th and 18th centuries indicate that it was also not uncommon for yeomen, gentlemen and farmers – or rather their wives – to grind small amounts of malted grain for home consumption. William Harrison, writing in 1587, records how his wife ground ‘good malt upon our quern’ to avoid paying a toll. Such mills tended to be found in the malt or brew house, or in the kitchen, stable or barn. Refined white bread continued to be the province of the wealthy. According to Fynes Moryson, writing shortly after the death of Elizabeth I (1603), ‘the English husbandmen eat barley and rye brown bread and prefer it to white bread as abiding longer in the stomach and not so soon digested with their labour, but citizens and gentlemen eat most pure white bread’. Boiled puddings, however, became increasingly popular with rich and poor alike following the invention of the pudding cloth in the early 17th century. They varied from plain batter puddings to rich plum puddings with mince and raisins, to thick oatmeal puddings. Barley was not only used in the brewing industry but also for the distillation of gin and whisky. Gin (from genever which in turn derives from juniper, which gives the drink its distinct flavour) originated in the Netherlands. It was first drunk in Britain in the early 17th century and became popular during the reign of William and Mary and more so when the government, partly due to the wars with France and in an effort to combat smuggling, encouraged its production, making it cheaply available to all classes of society. Gin shops abounded and it is estimated that by the 1730s Londoners were each drinking two pints of gin a week. To combat the increasing social problems of excessive gin drinking, the Gin Act was passed in 1751 which forbade the selling of gin to unlicenced merchants. Tea drinking was promoted, as was beer – the healthy happy lives of beer drinkers were contrasted with the misery and evils associated with gin drinking in William Hogarth’s Beer Street and Gin Lane engravings published in 1751. Today gin is a more sophisticated drink, and some 95 different brands are produced in the UK, the combination of botanicals that give each one its unique flavour well-kept company secrets. Whisky has been made in Scotland and Ireland since at least the 15th century. The Old Bushmills Distillery, County Antrim, established in 1608, is the world’s oldest licensed distillery. Following the Acts of Union in 1707 and the Malt Tax of 1725 much of Scotland’s whisky production was driven underground, being carried out illegally under cover of darkness – hence moonshine – a practice that continued until the passing of the Excise Act in 1823 which enabled the legal, licenced distillation of whisky once more. Today there are literally hundreds of different single malts and blends available. Starch, a carbohydrate found naturally in cereals, is converted to sugars during the malting and distilling processes, but when extracted from the plants and mixed with water it can be used as a food thickener, a stiffening agent for linen and cotton and a size for glazing paper. It was also used in the 17th and 18th centuries for powdering hair and wigs. Starch was generally produced from low grade flour. Indeed, a royal proclamation issued in 1629 stated that it could only be made from pollard (fine bran with a small amount of flour) and bran. The introduction of silk bolting cloths for sieving in the mid-18th century enabled the production of a finer white flour than had been previously available through those made of canvas, linen or wool. This coincided with the recipes for lighter cakes, biscuits and pastries that appeared in the cookery books of the later 18th century. More importantly, white bread which was once the province of the wealthy became available to the poorer classes of society. |

| The first half of the 19th century, however, was not good for the poor. The price of grain and, therefore, bread, which had been high during the wars with France, was kept artificially so with the introduction of the Corn Laws in 1815 which taxed and thus curtailed the importation of foreign wheat. It was not until 1846, following bad harvests and the potato famine which left many facing starvation, that the Corn Laws were repealed, and the price of bread reduced. In the second half of the 19th century the development of roller milling coupled with the increased importation of hard wheats that were naturally higher in gluten than native soft wheats, enabled the provision of a well-risen white loaf that was available to everyone. The late 19th and early 20th centuries saw the beginnings of scientific analysis of different wheats and flours, flour bleaching and the use of additives and improvers. |

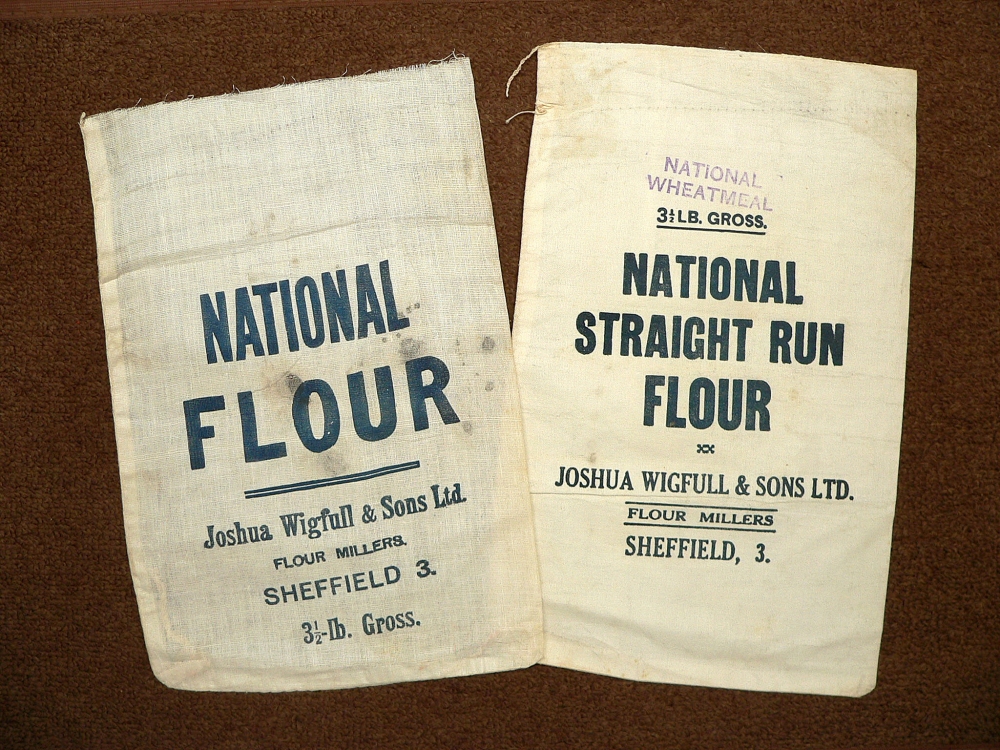

| Flour milling was taken into government control during the course of the First World War (1914-1918). Prices were fixed and extraction rates set; the higher the extraction rate the more of the whole wheat grain the flour contains. In 1917 the Cake and Pastry Order prohibited the selling of such products. The government moved more swiftly to take control at the start of the Second World War (1939-1945) and controlling agencies were set up to manage all aspects of flour production. The slogan ‘Bread into Battle’ was adopted, although interestingly bread was not rationed until after the war in 1946. Despite extra land brought under cultivation, wheat still took up much of the shipping space in the convoys coming across the Atlantic from America. It was claimed that too many crusts were being thrown away each day or given to pigs or chickens and that half an ounce of wasted bread per person per day across the country amounted to a shipload of grain every twelve days, that is, thirty ships a year. Thus ‘a wasted crust can mean a wasted convoy’. Recipes were devised for using stale bread, such as Poor Knights Pudding – slices of bread dipped in sweetened milk, fried and served spread with jam. In 1942 a National Flour of about 85 per cent extraction rate was launched which contained about 90 per cent wheat and 10 per cent other grains such as barley, oats and rye together with authorised additives and improvers. National Flour was finally discontinued in 1956. The 1950s and 60s saw the rise of large milling and baking combines such as Allied Bakeries and Rank Hovis McDougall which, together with the growth of supermarkets and the wonders of advertising, led to brands of conveniently sized, sliced, wrapped white factory loaves becoming household names. The Chorleywood Bread Process, adopted in the early 1960s, enabled the mass production of loaves, which it was claimed were softer and whiter than ever before. The replacement of the time-consuming period of traditional dough fermentation by rapid high-speed dough mixing cut preparation time down to less than an hour. By the 1970s such loaves accounted for some 80% of Britain’s daily bread. Bread consumption, however, has dropped over the last 100 years due to the increasing popularity of other cereal products such as rice and pasta, breakfast cereals and also other foods such as chips. Cornflakes (from maize) were first developed as a health food by Dr Kellogg in America in 1894 and Rice Krispies followed in 1928. Muesli was similarly devised as a health food in Switzerland about 1900. | |

| An increase in the demand for natural foods in the 1970s and 80s brought with it an increase in the demand for wholemeal loaves and led to the revival of the craft baker. The larger companies also responded to the demand. Today we have a wide choice of breakfast cereals, different varieties of pasta and rice, a variety of flours for home baking and an array of continental and exotic, as well as more traditional, cakes and breads and also an increasing range of gluten-free products. Comparable changes also occurred in brewing which during the later 19th and 20th centuries became an increasingly large-scale, commercial, automated industry, dominated by a few well-known companies. In 1971 the Campaign for Real Ale (CAMRA) was founded to promote cask beers and the traditional British ‘pub’. Since then, there has been an increase in the number of small-scale independently owned micro or craft breweries, so that today a wide range of different beers and ales is available across the country. From the largest multinational companies to the smallest backyard brewer and home baker, milled grains remain the key ingredients in what are probably our oldest, most continuous food industries. | |