| The Montefiore Windmill is a landmark in Jerusalem. Built in 1857, it was funded by British Jewish banker and philanthropist Moses Montefiore and constructed by the Kent firm of millwrights, Holmans of Canterbury. It was restored in 2012 by Vincent Pargeter and Willem Dijkstra. This history of the mill is taken from the work Holman Bros., Millwrights of Canterbury: A history by Geoff Holman, completed by Guy Boocock and published on our website: https://new.millsarchive.org/2015/03/10/holman-bros-millwrights-of-canterbury-a-history/. | |

Sir Moses Montefiore

| Judah Touro, the son of a cantor, was born in Newport, Rhode Island, and went to New Orleans in 1801 from Boston. He learned the merchant trade from his uncle and as a commission merchant with investments in steamships and real estate, he gradually amassed a fortune. He willed $10,000 to the North American Relief Society for the Indigent Jews of Jerusalem through their agent Sir Moses Montefiore, the son of an Israeli family which had moved to England. | |

via Wikimedia Commons

https://commons.wikimedia.org/wiki/File:Moses_Montefiore_1881.jpg

| In 1824, Sir Moses decided to retire from his successful financial career and dedicate his resources to aiding his fellow Jews. He visited Jerusalem for the first time in 1827. Over the next half-century until his death at the age of 101 in 1885, Sir Moses championed the cause of equal rights for Jews throughout the world. The poor of the Holy Land were Sir Moses’ favourite charity and despite the difficulties involved at that time both in travel overseas and travel within the Holy Land, he made seven pilgrimages to Jerusalem in his lifetime. In the mid-1850s, Sir Moses who still had financial interests in the City of London, and lived in the Isle of Thanet, interested himself in the plight of the poorer Jews in Jerusalem. Sir Moses and an American Jewish businessman, Gershom Kursheedt were concerned for the poor of Jerusalem and planned to build a hospital for them. All the inhabitants at that time lived within the walled city and conditions were very overcrowded and insanitary. In 1855, Sir Moses had a bequest made to him by Judah Touro of New Orleans ‘to ameliorate the conditions of our unfortunate brethren in the Holy Land’. The Rothschilds had meanwhile provided an adequate hospital so Montefiore and Kursheedt built a long, one-storey row of apartments to serve as dwellings for the homeless. This was named Mishkenot Sha’ananim, meaning ‘peaceful dwellings’ or ‘quiet resting places’. Sir Moses went to Jerusalem in 1855 to determine the specific form of the project. On his return home he decided not only to provide a livelihood for the residents of his newly acquired land but also to help the poor by reducing the price of flour. Both of these aims, he felt, could be achieved by the erection of a windmill to grind corn, which had previously been done using hand or horse driven mills. | |

The Holmans

https://catalogue.millsarchive.org/thomas-richard-holman

| After seeing examples of Holman mills in Thanet, Thomas Holman and his brother John James were commissioned by Sir Moses Montefiore to erect the windmill under the direction of the Society for Assisting the Jews. An agreement was signed to build the mill for £1,450. The design was for a tower mill built of local stone which it was hoped would withstand earthquakes. Although the building materials could be easily obtained in Jerusalem, the mill mechanism could not and so all the iron parts and running gear were made in Canterbury and transported by sea to Jaffa. Early in 1857, Thomas Richard went out to superintend the work. His passport gave free admission to Germany, France, Turkey, and Palestine, in case the overland route was chosen on the return journey. He travelled out by boat via Alexandria. A cheque for £17.10.0 was sent to the Australian Mail Co. in March 1857 – presumably for his fare, taking a foreman with him, and employing Arab labour. | |

https://catalogue.millsarchive.org/mr-holman-and-his-employees

| The machinery was all made and fitted at the works in Dover Street, sent by sea to Beirut where goods were transferred to an Arab coasting vessel and taken to Jaffa, where it was landed with much difficulty. The landing stage at Jaffa was not strong enough so the coaster was run close inshore and the individual pieces dragged ashore in small boats by 40 men with ropes. | |

| There were neither roads nor carriages, so everything was taken on camels and horses with the aid of many men, with a guide leading the way, each part being assigned its own cart, horses and a team of up to forty men with Thomas Richard following on horseback. It was 35 miles. Before the paving of a road from Jaffa to Jerusalem in 1869 the trip from the port to the Holy City took sixteen hours. It took 4 months to transfer all the machinery to Jerusalem and during this time the millwright was supervising the building of the tower. The following were listed in Thomas Richard’s pocketbook: Contents of clothes box. Case of Gingerbread, Biscuits, Plum Cake, Cannister of sweets, 5 Pairs socks, 4 Pairs stockings, 6 Scarfs, 4 Neck ties, 6 Towels, 4 Small do., 1 Face cloth, 1 Duster, 3 Flannels, 9 Shirts, 8 Handkerchiefs, 4 Coats, 3 Waistcoats, 3 Pairs trousers, 1 Slop, 2 Pairs drawers, 2 Hats, 3 Pairs braces, Linen Rag, 2 pairs shoes, Shoe laces, Looking glass, Paper & ink, Knife, Fork & 3 Spoons, 4 Books. Contents of toolbox. 6 Augers, 1 Handle, 1 Axe, 4 Saws, 1 Strait edge, 11 Chisels, 1 Screwdriver, 2 Planes, 1 Rabbit plane, 7 Brad awls, 9 Gimlets, 3 Gauges, 1 Spokeshave, 1 Bevil, 1 Pair pincers, 3 Prs Caliphers, 2 Chalk lines, 5 Punches, Pencils, Spirit level, 1 Mallett, 2 Hammers, 1 Pair trammels, 1 Oil stone, 5 Files, 6 Hand saw files, 5 Cold chisels, 2 Squares, T spanner, 2 Papers, 1 Box instruments, 1 Pair compasses, Sand paper, 3 Brushes, 1 Bottle blacking. Also listed were wages: Masons 16 Piasters per day, Labourers 5 Piasters, Boys 3 Piasters. Miller requires 20 piasters per day and house to live in. Price of lime – 35 piasters per coutar delivered on the spot. Water 100 piasters per 200 skins. Camel will carry 600lbs. Paid Anna watchman up to July 10th 150 piasters. There was the Arabic alphabet together with some translations from Arab to English, including – Ah teem shwyez saboon – Give me some soap. Enta Sithus – What for. Anna areed shwyez titten – I want some tobacco. There were lists of names of camel drivers and loads carried and time sheets of masons employed showing which days they had worked. In August 1857, 257 donkeys were hired to transport water, building materials, lime, and wood. | |

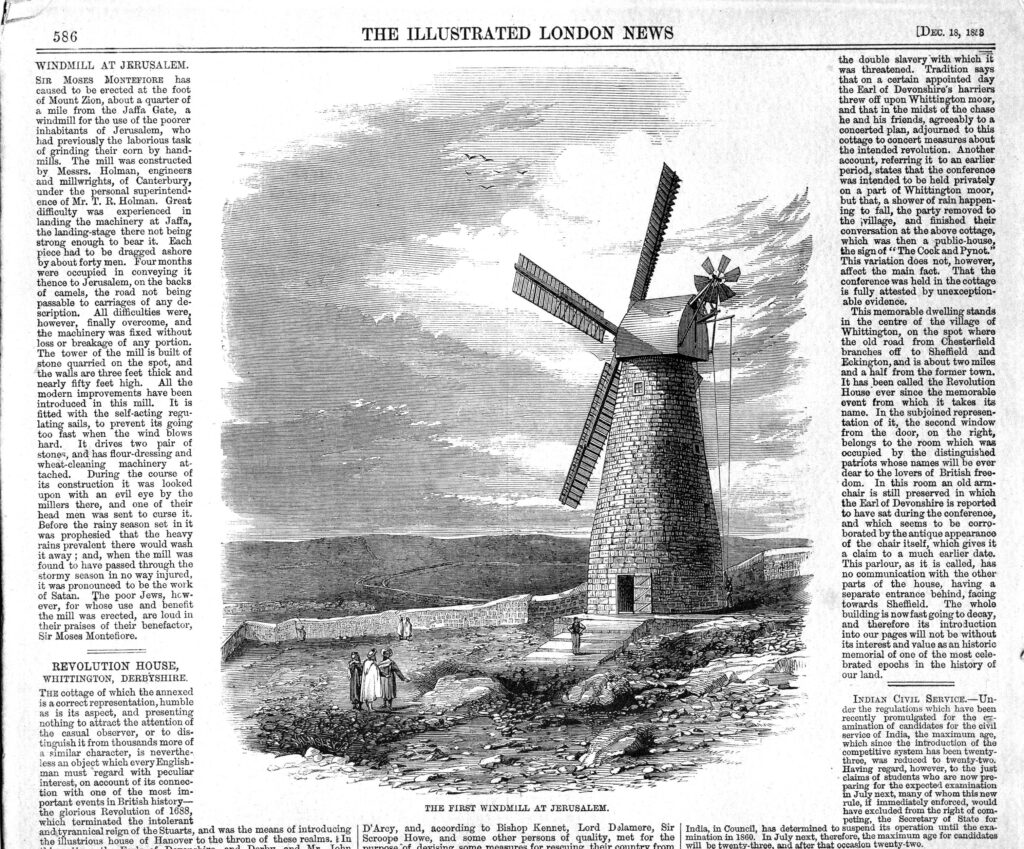

Construction of the mill

https://catalogue.millsarchive.org/article-on-montefiore-windmill-jerusalem

| The mill was built at the foot of Mount Zion about a quarter of a mile outside the Jaffa Gate. The first stone of the mill was laid on 5 May 1857. The tower of the mill was built from stone quarried locally, and lime, ashes (from the Baths) and water were carried to the site in baskets and skins on donkeys and camels. Local masons were employed and the hours worked were 6 o’clock until 6 in the evening. The wages paid per day were labourers 5 piasters and boys 3 piasters. It was the custom of the Arabs to demand baksheesh every morning before starting work and the mill was looked upon with an evil eye by the local millers one of whose head men was sent to curse it. A further cheque for £52.10.0 was sent to the Mail Company in August 1857 when the millwright’s brother, John James, went out as escort to two millwrights, Kemp and Mace, who were to install the machinery. Once at Jerusalem the parts were incorporated into the windmill. The stone tower was round, 21 feet diameter and 3 feet thick at the bottom, then cylindrical upwards for 10 feet, then tapering for 32 feet to 11 feet with 2 foot 9 inch thickness at the top and surmounted by a lead covered, traditional Kentish wagon-shaped cap. The sweeps, manufactured with the rest of the machinery in Canterbury, included what the Illustrated London News was pleased to call ‘the very latest invention’ – William Cubitt’s patent sweep design. They were double-shuttered with eleven bays of 2 shutters each, 6 bays on the midling, and 5 beyond with a span of 60ft. The high mounted fan-tail had a diameter of around 8 feet. A cast iron windshaft carried a brake wheel driving the usual upright shaft which had a six-spoked cast iron spur wheel, with wallowers driving the 2 pairs of millstones. There was also a drive to the wheat cleaner and flour dressing machines. In addition to the ground floor, there were 2 further wooden floors above – the stone floor and the wheat bin floor. It took about 18 months to complete the mill. At the end of that time Thomas Richard went down to Jaffa to inspect the wells in connection with the irrigation of the orange gardens there. While there he contracted dangerous Syrian fever, and he was nursed back to health by an American lady doctor. On Friday 27 February 1857 the Jewish Chronicle and the Hebrew Observer, advertised for a miller: | |

Wanted, for the holy City of Jerusalem, a JEWISH MILLER who thoroughly understands the working of a Windmill with self-acting sweeps, DRESSING the STONES, and the requisite adjustment of a Flour-machine working with a Wired Cylinder and revolving brushes. Applications by letter, giving reference: respecting ability moral and religious character, &c., to be addressed to Alexander J. Montefiore, Esq., Alliance Office, Bartholomew Lane, London.

| Sir Moses Montefiore arrived at Jerusalem to inspect the mill on 20th May 1857. The mill was eventually completed in spite of prophecies that the heavy rains of the rainy season would wash it away. When it was seen to have withstood the rains it was pronounced the work of Satan. The poor Jews, however, were duly grateful. A miller was employed and instructed and he asked for 20 piasters a day and a house to live in. One report has it that the Arabs were fond of drinking lubricating oil, and even licking greased bearings for sustenance. A leg of pork was eventually hung in the oil storage barrel which stopped the practice. The instructions of Sir Moses, that the price of flour be cheaper for the poor, were at first followed. | |

https://catalogue.millsarchive.org/montefiore-windmill-jerusalem-4

| A picture taken by M.J. Diness in April 1858 shows that the mill was complete with the shutters of the sweeps closed, indicating the mill was still working by wind. This and other old pictures show white paint on the roof and woodwork of the sweeps which, in the hot climate of Jerusalem, would have been a practical colour. In 1866 the Holmans replied to questions sent by Isaac Rosenthal, Moses Montefiore’s agent, as to whether repairs were required to the mill. They confirmed that the midlings were in good condition, but the sweeps, fantail and sweep rods needed painting. All the shutters had been blown out and 200 new ones were needed, framed and covered with stout canvas and finished with three coats of best white paint. The ironwork of sweeps was not broken. The brake wheel needed 72 new cogs of seasoned apple or beech timber. The spur wheel was in good condition, but the stone pinions were worn, all 50 cogs needing to be replaced. The stone spindles were not damaged. Two new step brasses were needed for the bottoms of the stone spindles and 50 new cogs for the stone pinions, to be made of well-seasoned apple or beech timber. Four new neck brasses were to be fitted to the lower stone boxes. Nothing was broken in the flour machine, but the brass boxes which the bottom of the stone spindles ran in were worn through and new ones were necessary. The roof of the mill was damaged in several places and the rain was coming in. A long new rope from England was also requested, as it could not be obtained locally. There was a request to send out ‘white colour’ ready and prepared to whiten all the damaged places, and for four mill bills with handle to furrow the millstones. | |

Later History

The mill worked until around 1876 with sundry repairs, but gradually fell into decay. The establishment of other flour mills, operated by steam, and the expense of spare parts and their transportation made Sir Moses’ windmill uneconomical and it stood unused for many years. By the early 1930s it was in poor condition.

It is as a landmark that the mill is best remembered in Jerusalem, but even though the landmark was cherished, nothing was done to preserve it.

The mill in December 1933

https://catalogue.millsarchive.org/jerusalem-mill-jerusalem-6

| Eventually a concrete roof was put on which incorporated (i.e. cemented in) the original cast iron windshaft. This may have been a mistake because the mill was used as a Hagana observation and machine gun post during the 1947–48 war. To hinder the Jewish defence, the British Army blew the top off with explosives in 1948; this became known as ‘Operation Don Quixote’ and must be unique in the windmill world. The tower was restored to its original height. In 1968 a copper cap, together with stocks and dummy sweeps were installed and the tower was repointed. Peter Halben, Director of Mishkenot Sha’ananim, remarked at the time that ‘a cherished landmark of Jerusalem’ – the Holman Brothers’ windmill was still in existence. The mill has passed into Jerusalem history as it has been represented on banknotes, greetings cards, stamps, and is a significant exhibit in the museum area of Jerusalem Mishkenot Sha’ananim. | |

Restoration

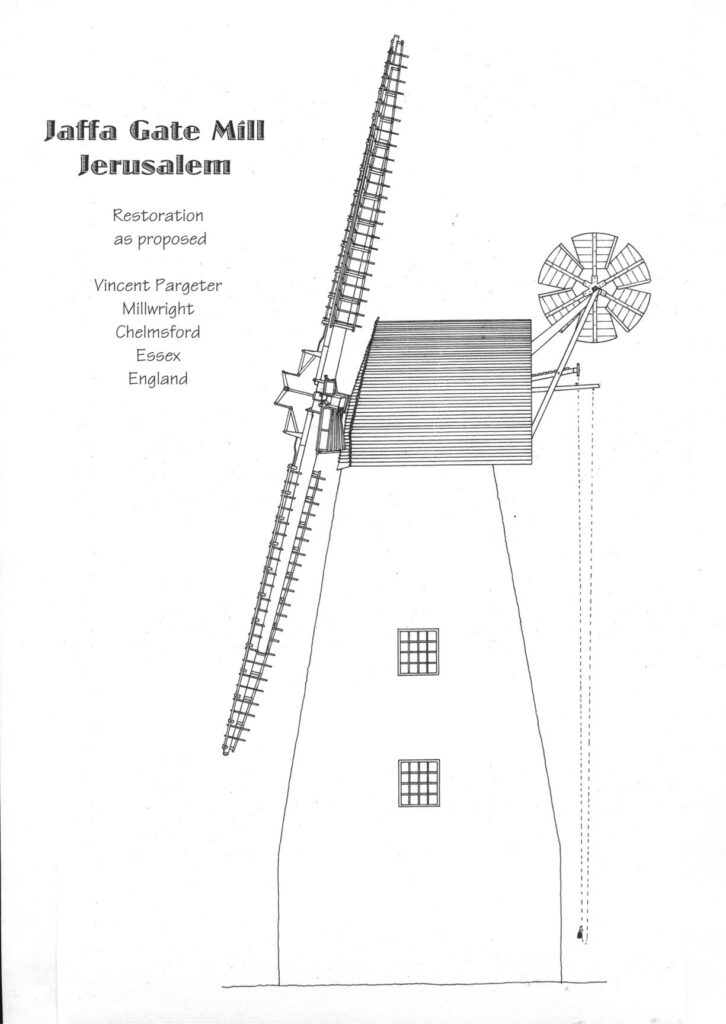

Between 2007 and 2012 the mill was restored to full working order. Dutch organisation Stichting Christenen voor Israël promoted the restoration. Drawings for the machinery were produced by millwright Vincent Pargeter, drawing on the Holman records held by Geoff Holman and evidence of their work from existing Kent mills which they built. The construction work was carried out by Willem Dijkstra and the sails turned again in August 2012.

Vincent’s drawings are all now held by the Mills Archive: https://catalogue.millsarchive.org/informationobject/browse?page=1&collection=556734&places=2996&levels=&findingAidStatus=&topLod=0&startDate=&endDate=&rangeType=exact&sort=lastUpdated&sortDir=desc

Vincent Pargeter’s plan for the restoration of the windmill

https://catalogue.millsarchive.org/jaffa-gate-mill-jerusalem-restoration-as-proposed-2