| Many articles from The Miller or Milling demonstrate the importance to the milling trade of conventions and exhibitions. Both these Victorian publications are held at the Mills Archive, along with the American Northwestern Miller. All three journals have some significant gaps, so we would welcome any offers of material as we continue to build the World’s first roller flour mill library and archive. A report in The Miller, January 7th 1884 (pp 838-9) describes the Islington exhibition in London. Milling engineers of the time were fully alive to the needs of millers as the demand for more efficient machines was forever growing. These snapshots give only a glimpse of the progress being made by some of the firms at that time. |

Buchholz and Co, founded by Gustav Adolf Buchholz , were commissioned by W Baker & Son to design a gradual reduction system to produce 5,000 sacks of flour per week in their new mill in Bristol, replacing one that had burnt down. The Buchholz system of flour making was highly regarded after its introduction in 1864.

Gustav Adolf Buchholz

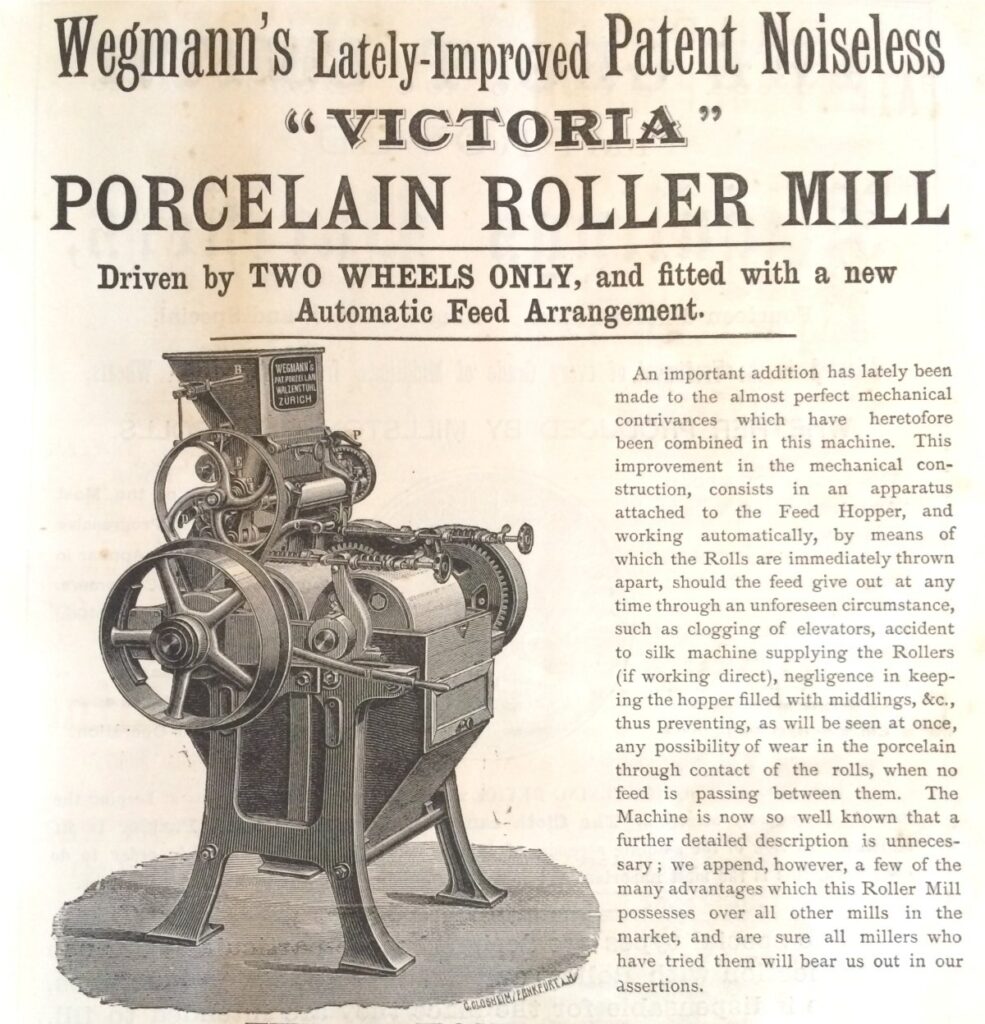

AB Childs & Sons of London had started up three mills on the Jonathan Mills’ system; one at Chelsea belonging to E Mead, another at Kirkaldy, Scotland owned by W Hogarth, and a third at Blackburn in Lancashire belonging to Appleby & Sons. The firm also had a large demand for their bran roller mill and Wegmann’s “Victoria” porcelain roller mill.

AB Childs advertisement for the Wegmann Victoria

| WR Dell & Son of London had just finished French’s mill at Bow in London, which would have a weekly output of from 1,500 to 2,000 sacks. The fact that millstones had not been totally superseded by rollers is underlined by their sales of 4-500 millstones during the year. |

Fiechter & Sons of Liverpool had secured four contracts for complete mills based on their automatic roller system. In their advertising they comment that in re-modelling stone mills to the roller process they could use all the old machinery if desired.

Fiechter’s Modified Automatic Roller Milling System

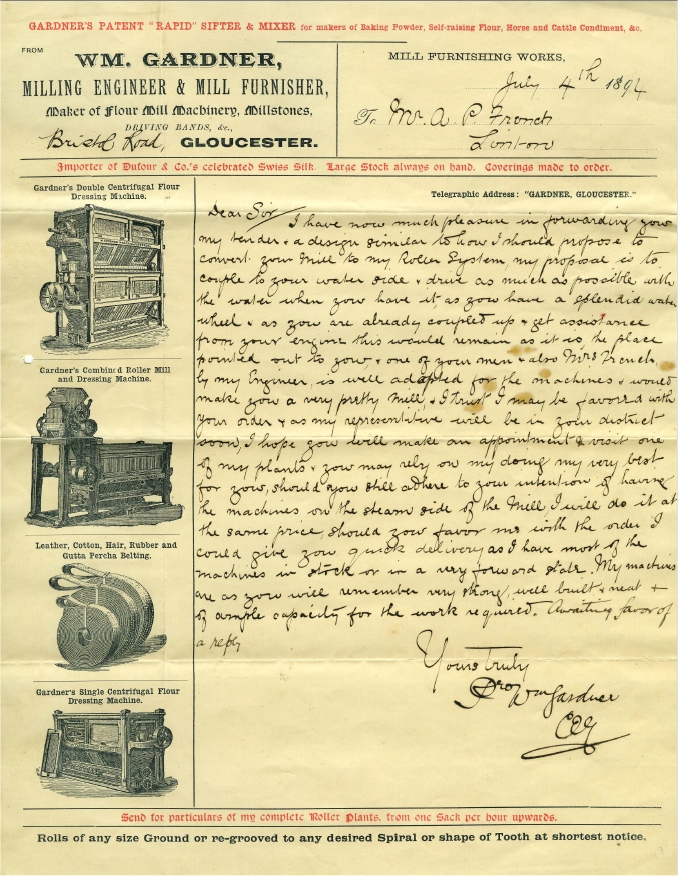

| W Gardner of Gloucester had also remodeled several mills. He had brought out a new centrifugal which he claimed had important new features and a new three-high roller mill. He had also a good trade in millstones for the UK and the colonies. In passing I should mention that a typical gem in the Archive collections is a tender from Mr Gardner to install a roller plant to be driven by the waterwheel at Hildersham Mills in Cambridgeshire. |

Howes & Ewell of 16 Mark Lane, London had been very active with wheat cleaning machinery and sold many of their improved flour packers, a machine which had been taken up during the year by the Royal Dockyard Mills, Gosport. Their “Little Giant” turbine was also selling well.

The Little Giant Turbine

| Fred Nell of Mark Lane London, working with Robinsons of Rochdale, had completed a number of contracts for complete mills on their roller system as well as introducing many improved machines of their own manufacture. Seck Brothers of Bockenheim and Mark Lane had been instrumental in starting up a large number of mills in the UK including Fitton’s new mill at Macclesfield and Leatham’s at York. Henry Simon of Manchester reported on his last three months in 1883. Together with current or proposed projects he would create new capacity of 45,250 sacks of flour a week. JW Throop had started on his second roller plant for AK Walker of Newry, Ireland making the capacity of his two Gray roller mills over 3,000 sacks of flour per week. He had also successfully started on the second half of J&H Robinson’s mill at Deptford, making the complete mill on the Gray system. He has also been responsible for setting up combinations of rollers and millstones. |

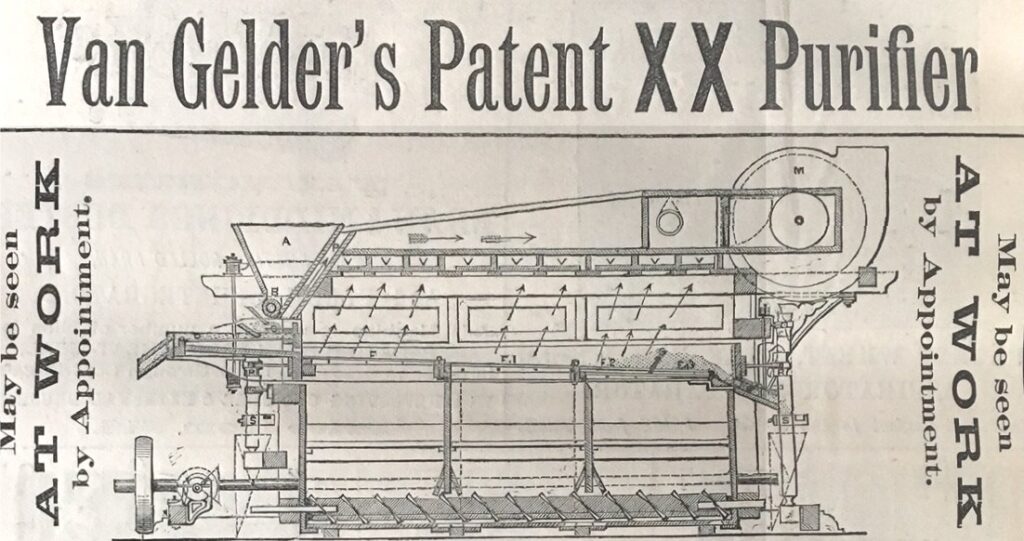

Van Gelder & Apsimon of Liverpool and Sowerby Bridge, Lancashire had had great success with their wheat cleaning system, many mills having installed it. Their “Triumph” dust collector, a new machine they had just brought onto the market was doing well along with their “XX” purifier.

Van Gelders Patent XX Purifier

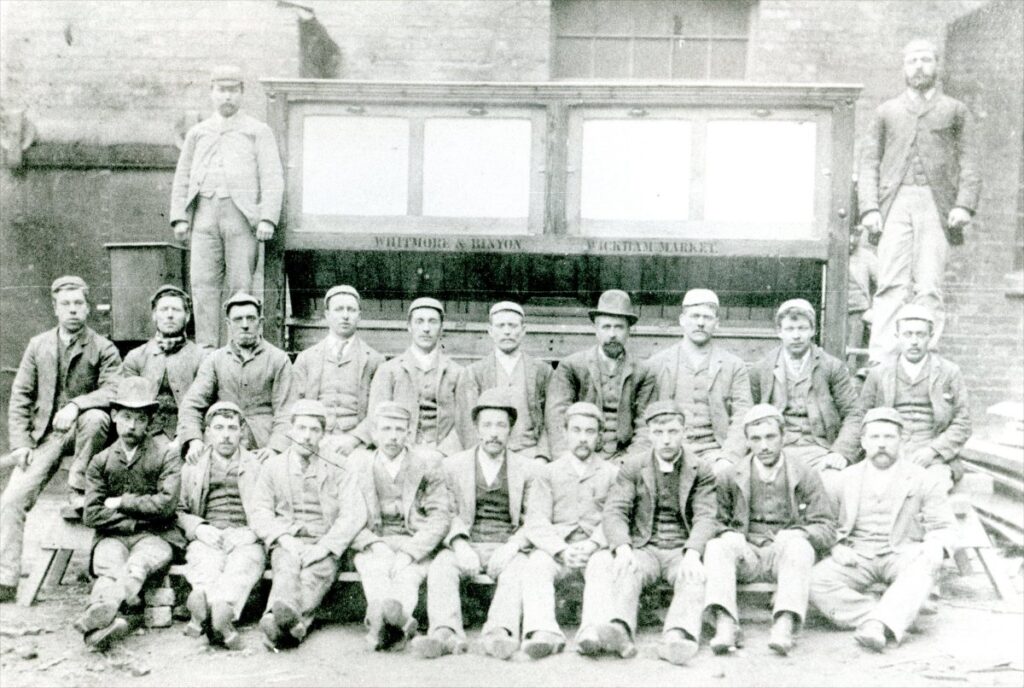

| Messrs Whitmore & Binyon of Mark Lane and Wickham Market had manufactured a large number of waterwheels, still indispensable to the many mills that relied on a good water supply to power their machinery. Various mills had also been remodeled on their system; the sales of their centrifugals and other milling machinery contributed to their increasing status in the trade. My final illustration, a photograph from our Archive collections, illustrates the pride that workers and engineers take in their products. |

| We have extensive files on Whitmore and Binyon and other milling engineers, but we are always looking for material to fill the gaps. If you have any, or know someone who does, please contact us. |