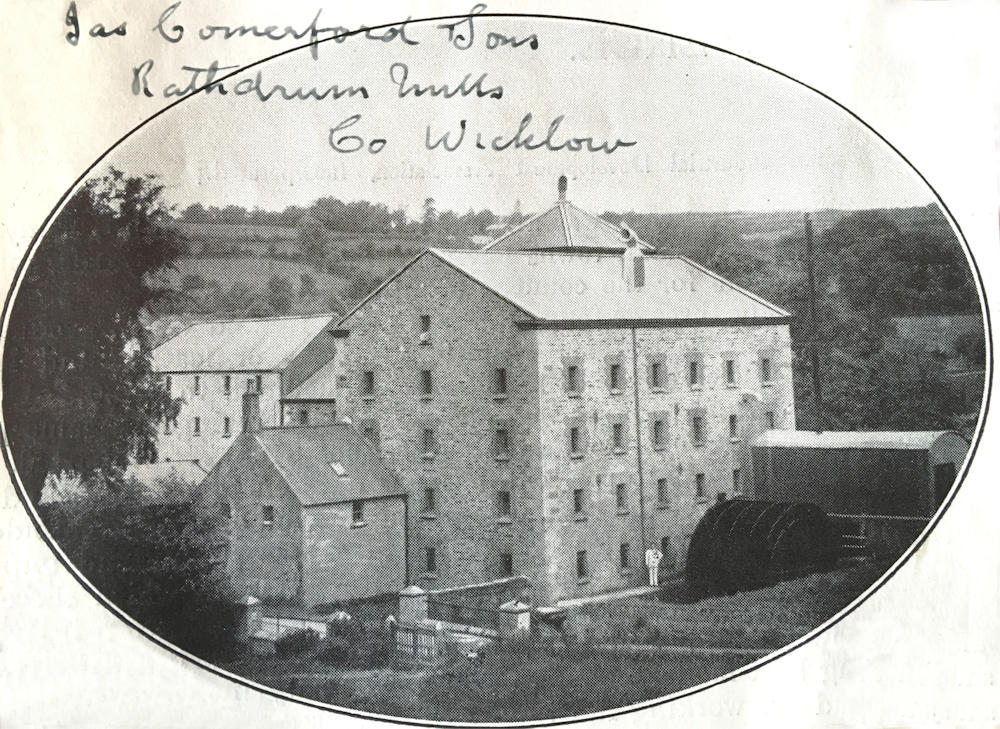

| As with my previous articles, I have chosen accounts from The Miller or Milling describing successful mills from the early days of roller flour milling. Both these Victorian publications are held at the Mills Archive, along with the American Northwestern Miller. All three journals have some significant gaps, so we would welcome any offers of material as we continue to build the World’s first roller flour mill library and archive. Comerford’s roller mills at Rathdrum in County Wicklow featured in a detailed illustrated article in the 7 June 1886 issue of The Miller. The mill, situated in the beautiful valley of the Avoca, had just been built on the foundations of the previous mill. Its predecessor had met the fate of so many other flour mills, with a disastrous fire a year earlier on 20th June 1885. At the time of the fire the mill had eleven pairs of millstones with 18 silk reels with purifiers and one set of rolls. |

The new mill, a four storied structure, was built of stone agreeably tempered by facings of red brick. The most dramatic external feature of the mill was the large waterwheel which provided the motive power for the mill.

It was a high breast-shot waterwheel 20 feet in diameter and 12 feet wide. It had ventilated buckets and a 26 inch shroud. The fall was around 12 feet and the wheel could produce 80 horsepower.

The owners were proud of the mill weir, which had been constructed under their own direction. The water for the mill came from a mountain torrent, which at the end of a severe winter, when masses of snow would suddenly melt under the April sun, would pour a swollen volume of water into the valley. Before the new weir was built flooding around the mill was a frequent event. The new weir, a semi-lune was built of concrete with massive stone walls and had a curved apron to break the force of the fall.

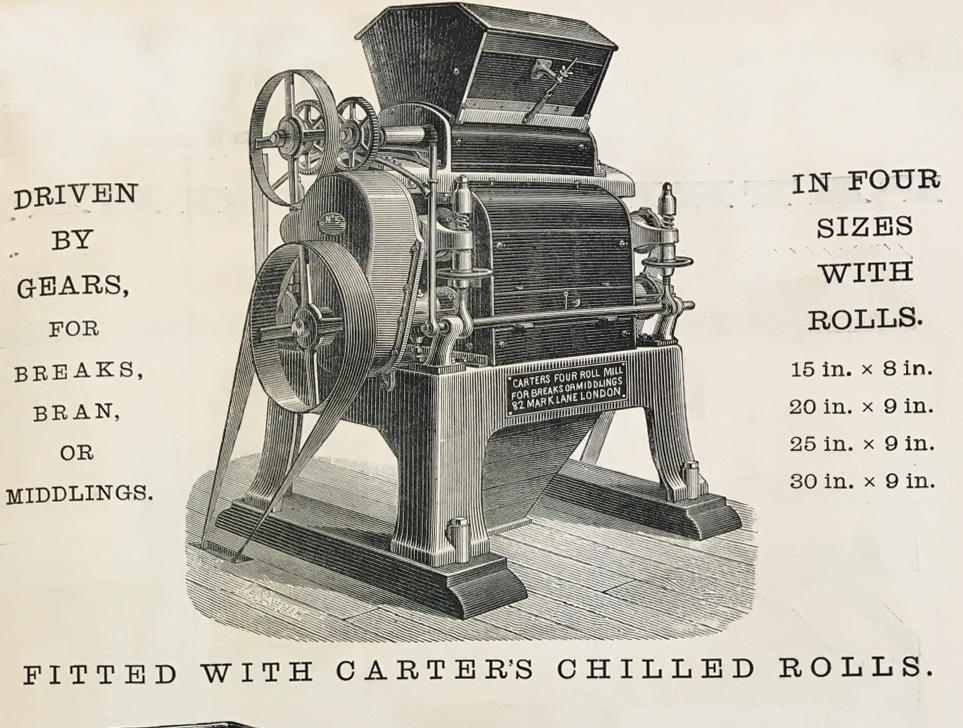

The mill had been fitted out with a full five sack per hour roller plant by

J Harrison Carter of 82 Mark Lane, London.

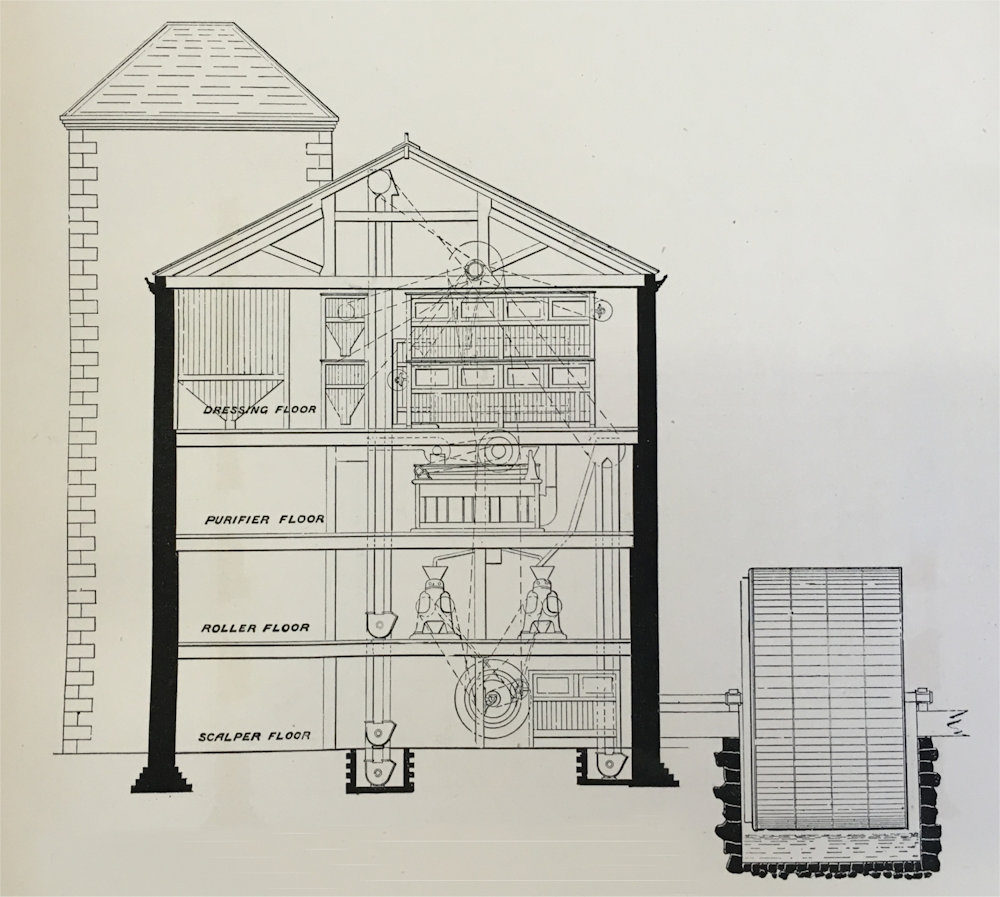

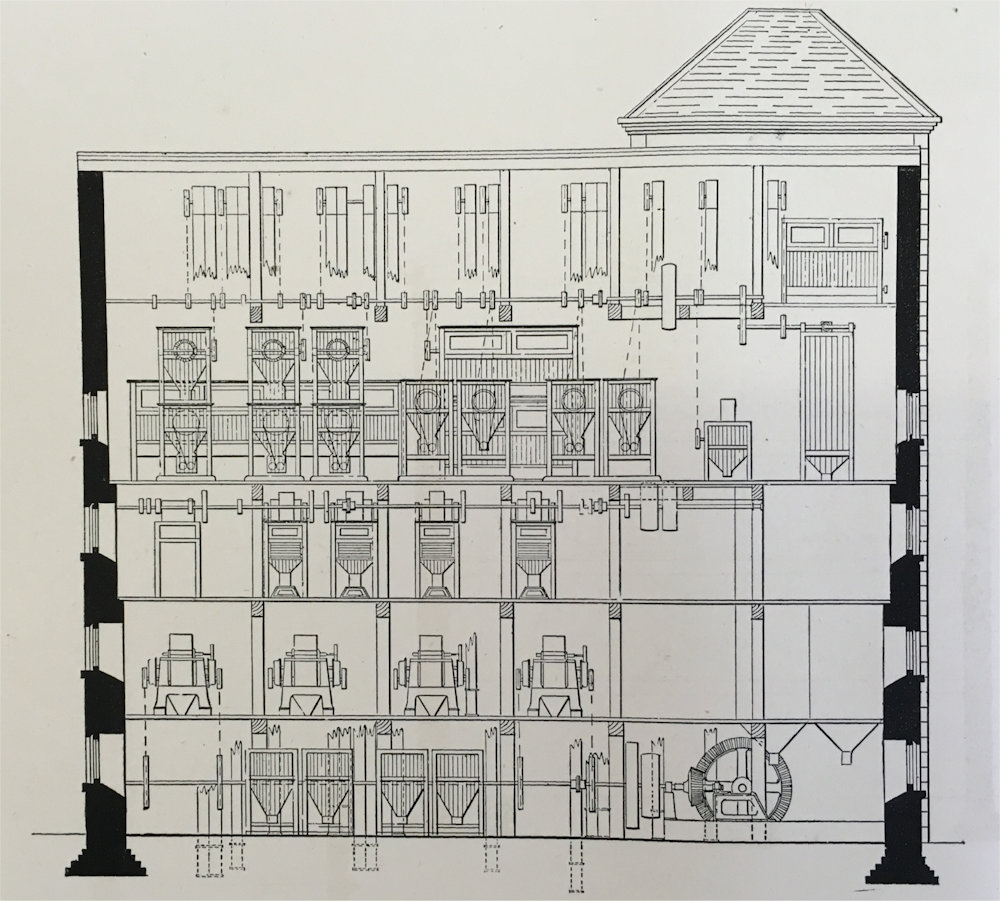

Cross Section of the mill in 1886 showing the 20 foot diameter waterwheel

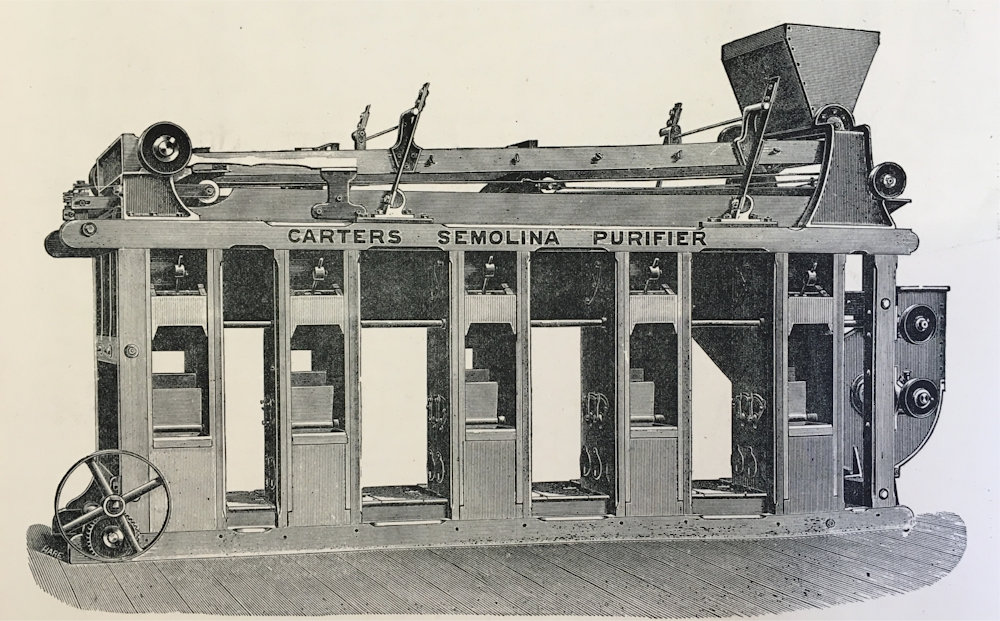

| All the rolls were of Harrison Carter’s latest design, furnished with four rolls and driven by gear drive. The main drive for the mill machinery was a spur wheel 11 feet in diameter turning at 18 revolutions per minute. The spur wheel drove a pinion 4 feet 6 inches in diameter, which set the main shaft in motion by means of a bevel gear. The pinion shaft turned at 47 rpm and the main shaft 125 rpm. On the main shaft various pulleys were fixed by which the roller mills on the floor above were put into motion. The wheat cleaning department was in a separate fireproof department adjoining the mill, and was connected to the top or fourth floor by double iron doors. A pulley, 72 inches in diameter drove the wheat cleaning machinery and another of 4 feet 6 inches drove the flour dressing machinery by means of a 12 inch belt. The first floor or grinding floor had eight sets of Carter’s roller mills placed in two rows. The second floor held sieve purifiers and a suction fan exhausting from the rolls, to take out light material that may have remained in the wheat. |

The third or top floor housed the dressing machines, namely six Carter’s centrifugals and eight long silk reels. These were put in motion by means of a 12 inch belt which connected the shafting on this floor to the shafting on the second floor.

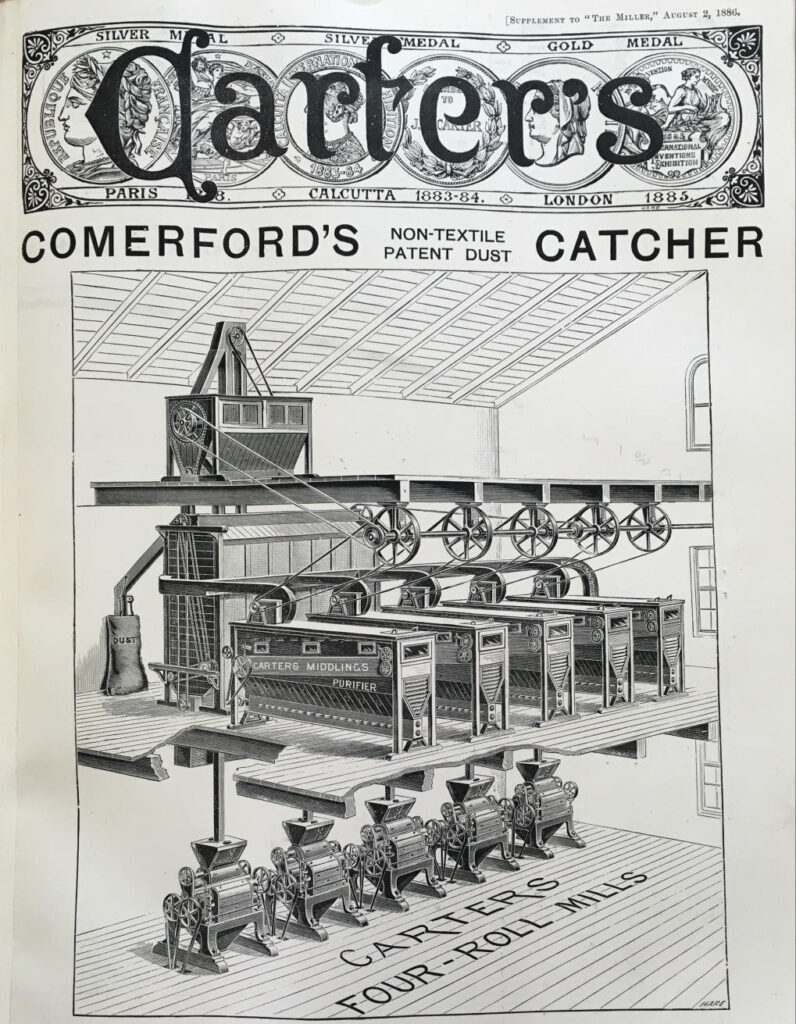

There were four wheat bins each capable of holding ten to twelve tons of wheat, built and installed by the millwright, Peter Murphy of Wexford. On this floor there was also the Carter dust collector, which had no textile material used in its construction, and which featured prominently in a Carter’s advertisement in August that year.

Longitudinal Section of the mill in 1886

Carter’s advertisement featuring Comerford’s dust collector