Manufacturers: J. Harrison Carter

James Harrison Carter was one of the leading British milling engineers of the 19th century. He had started his career as a practical miller, after being apprenticed to a mill in Sussex, but then went on to design machinery. He was part of the group that visited Vienna and Budapest, in 1877, to view the milling developments that had taken place there. The following year he was advertising his own chilled iron roller mills, and even exhibiting them in Paris, where he won a silver medal, and at the Royal Agricultural Show in Bristol, this latter display being described as ‘the first iron roller mill for flour mills ever exhibited in this country’ (TM, February 5, 1894, xxxvii.)

In the early days, Mr. Carter developed a partnership with Escher Wyss & Co., who provided the fluted rolls for the first part of his system. Indeed, at the 1881 Islington Exhibition of machinery, Carter displayed six machines produced by this company that were used for the ‘reductions of the wheat’ (TM, June 6, 1881, p.269). The machines were made of ‘chilled iron, and spirally fluted, the grooves of flutes being finer in each machine from the first used for the series of reductions’ and played a pivotal part in the ‘Carter System’ (TM, June 6, 1881, p.269).

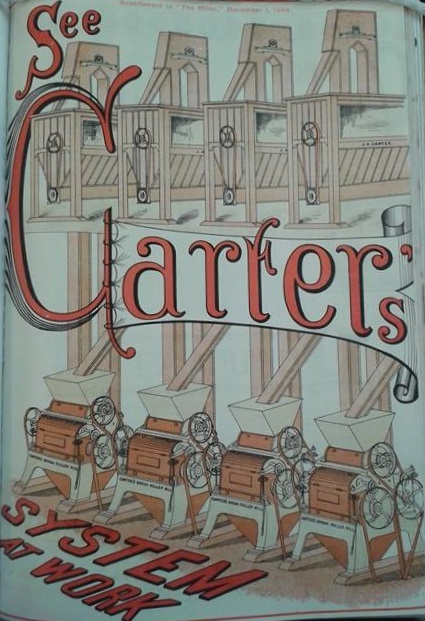

This ‘Carter System’ could be seen working at the 1881 exhibition and was described in a later edition of, The Miller:

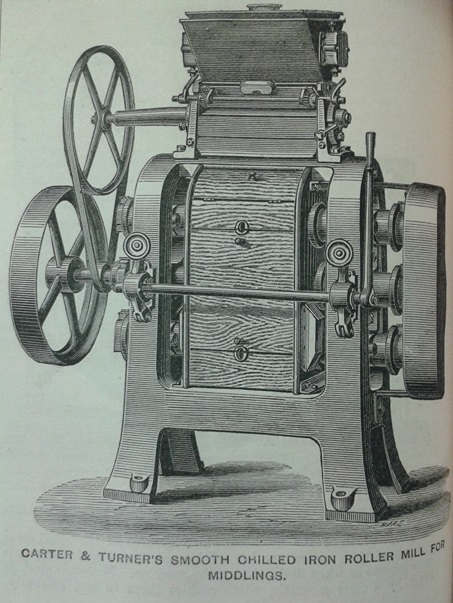

‘Mr. J. Harrison Carter, of Mark Lane, takes as the motto for his system of milling to avoid grinding the bran and mixing it with the white flour. He cracks open the wheat-grain by fluted rollers so lightly that this first operation does not produce more than one per cent of flour. The grain in halves is then divided by a second pair of fluted rollers, and passes through four or five breaks; the products of fine flour, middlings, and semolina being dressed and sized at each stage, and the middlings crushed through smooth rollers.’ (TM, June 6, 1881, p.299)

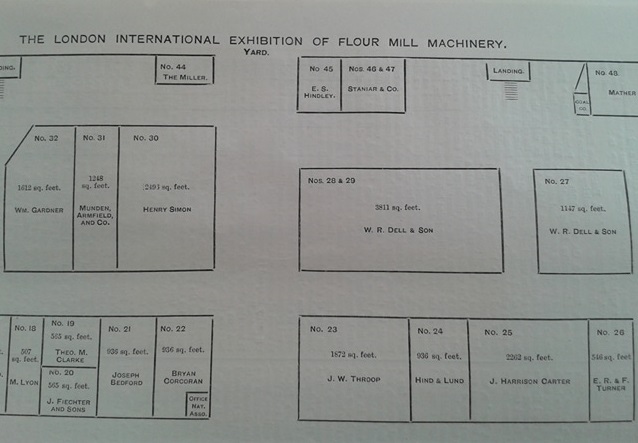

The ‘fluted rollers’ in this description were the ones produced by Escher Wyss & Co. However, the smooth rollers used for the middlings were not produced by that company. Instead, Carter formed an association with another engineering firm, E. R. & F. Turner. They produced the machinery for the middlings and around 1882/3, they also started producing the break rolls, replacing Escher Wyss. The partnership with E. R. & F. Turner benefited both firms, Carter would take care of the marketing, installation and commissioning of a plant whilst Turner’s produced the machines; the ‘mechanical engineering design’ was done ‘both by Turners and within Carter’s own firm’ (Jones, 2001, p.103).

This change of engineers is represented in Carter’s installations. In 1880, he installed his first major installation, replacing 41 pairs of millstones in Ringsend Road Mill, Dublin. This mill was owned by the bakery firm, Patrick Boland and the order was given by James Mooney. This installation included break rolls produced by Escher Wyss and was considered by Carter to be the ‘First Automatic Roller Plant in the World’ (TM, February 5, 1894, xxxvii.). Three years later, Mooney hired Carter again, this time to replace 15 pairs of stones in the newly acquired Clonliffe Mills, Dublin. In the 10-sack-per-hour plant Carter installed, no Wyss rolls were used, only machinery produced by E. R. & F. Turner.

After the 1880 installation, Carter’s success grew. He made prominent installations for Messrs John Greenwood & Sons Mill, Blackburn, and Messrs. John Davidson & Sons’ Phoenix Flour Mills, Newcastle-Upon-Tyne. These installations added to his prestige and between June 1884 and June 1885, he had ‘started or received orders for 33 complete roller mill plants’, including three 40 sacks per hour plants for McDougall’s in Manchester. (Harris, p.73).

In Britain, he was gaining a reputation as a ‘distinguished…member’ of ‘the ranks of flour mill engineers’ (TM, Jan 7, 1889, p.451). Yet this was also a reputation he was gaining worldwide. In The Miller, there are mentions of installations by Carter throughout the world, from the Société des Moulins de Prouvy, France, to the Corinto Flour Mill, Chili. However, Carter’s greatest foreign success was in Ireland. As already mentioned, his first major installation took place there in 1880, but many more followed. Although specific figures are unknown, there is evidence, put forward by Glyn Jones, that during 1884-5, Carter was ‘supplying plant to W.P. & R. Odlum at Portarlington, R. & W. Pilsworth at Thomastown, and R.W. Newton at Londonderry’ (Jones, 2003, p.115). By 1886, he was reported to be equipping a ‘large new mill for Messrs Russell at Limerick’ and J. Comerford in Rathdrum, read more about the Comerford mill here (Jones, 2003, p.115). Indeed, only Henry Simon Ltd. could rival Carter for the number of installations undertaken in Ireland.

The success of the Carter firm was not just down to J. Harrison Carter. As already mentioned, E. R. & F. Turner produced most of his machinery and they appeared as joined patentees for some of these machines. The middlings roller mills that Mr. J. Harrison Carter exhibited at the Islington exhibition, ‘were the production of the joint patentees, Messrs Carter and Turner’ (TM, 6 June, 1881, p.258). Carter’s manager, Gilbert Little, was also a key part of the firm, designing many mills, and an active member in the wider milling industry. At the nabim convention held in Dublin in 1886, he read a paper entitled ‘Shall we Utilise the Latent Abilities of the Operatives Engaged in Milling?’, which was then published in The Miller, 5 July 1886. In the paper, he suggested the formation of a committee ‘whose functions it shall be to decide upon the merits of inventions or discoveries submitted to them by workmen, and the granting of money awards where warranted’ (TM, July 5, 1886, p.189). There was no time to discuss the ideas forwarded in this paper but they were deemed so important that Mr. Ure of Glasgow proposed that the paper ‘be remitted to the Council for their consideration’, a motion that was ‘unanimously adopted’ (TM, July 5, 1886, p.199).

On the 3 December 1888, an ‘Important Notice’ appeared in The Miller. Mr. J. Harrison Carter announced ‘he will retire from his present business as Milling Engineer, and that Messrs. E. R. & F. Turner of Ipswich…have purchased his Stock and Interest’ (TM, Dec 3, 1888, p.ii). Many of the staff were kept on by Turners but otherwise, it appeared that the J. Harrison Carter firm had ended. However, Mr. Carter’s retirement only lasted six years as in 1894 he announced he was to ‘set up a milling engineering firm in Dunstable’ (Harris, p.73). He worked in this establishment until his death in 1906. The following year, his firm was turned into a private limited company, which the Carter family maintained control of. J. Harrison Carter Ltd. continued to produce ‘conveyors, elevators, disintegrators, grinding crushing, sifting, drying and mining machinery’ until around 1969, when the company was acquired by E. R. & F. Turner (Harris, pp.73-74). Once again, the firm of J. Harrison Carter had become amalgamated with E. R. & F. Turner as the history of two firms remained ever interlinked.

Read more about Mr. J. Harrison Carter here.

Sources:

*Image of Odlums, Wikimedia Commons, Fennel Photography, licensed to use in Creative Commons (CC BY-SA 4.0) https://creativecommons.org/licenses/by-sa/4.0/deed.en*

Harris, Nigel S., Wheat Flour Milling from Millstones to Rollers (2017).

Jones, Glyn, ‘The Introduction and Establishment of Roller Milling in Ireland, 1875-1925’, in Andy Bielenberg (ed.), Irish Flour Milling: A History 600-2000 (Dublin, 2003), pp.106-132.

The Miller, December 3, 1888.

The Miller, February 5, 1894.

The Miller, January 7, 1889.

The Miller, July 5, 1886.

The Miller, June 6, 1881.