From Mill to Shelf: Transport (part 2)

Once the wheat has gone through the milling process and the final flour product has been packed into sacks or barrels, it has to be transported from the mill to the towns and markets where it will be sold. Initially, this meant that the sacks had to be loaded up into the back of a cart to be taken away.

Loading the Cart:

A cart pulled by two horses could manage a load of five tons, providing the deliveries were local and on flat terrain. However, for hilly terrain and deliveries further away, more horses were needed and the load was often lessened. For the expanding flour milling business, given the advance to roller machinery, this was no longer going to be enough.

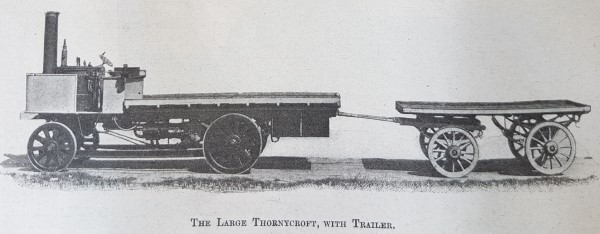

The first major change took place around 1900 with the arrival of steam powered transport. The world of milling took advantage of this new method and the different engines available on the market. One of the first companies to make steam lorries was J. I. Thornycroft and Co. who made their first one in 1896:

This is an example of their steam traction engine from an edition of The Miller in 1899. Such an engine and trailer could manage around 12 tons of flour and could travel further distances than the horse and cart.

Steam waggons and lorries were also popular at the time and were produced by a variety of companies including E. Foden, Sons and Co. (made their first steam waggon c.1900); T. Coulthard and Co. of Preston (made their first steam waggon c.1905); and the Sentinel Waggon Works of Shrewsbury, established by Alley and MacLellan of Scotland in 1906. Steam waggons produced by these companies became common on the road:

T. Coulthard and Co. Steam Lorry from The Miller, 03.06.1899:

Steam Lorry from Abbey Mills, Reading:

This transition was a memorable event but steam power was not without its issues. In his work, Graham Edge records some of them:

‘They needed a couple of hours to raise steam before setting out each morning and the risk of water running low in the boiler was always a concern for crews…Returning to the mill after a long and tiring day it was not a case of switching off the engine; the fire had to dropped and the coals thoroughly doused.’ (Edge, p.23)

Steam power was therefore not without its difficulties so an alternative method was soon embraced. In a history of E. Marriage & Son Ltd. of Colchester and Felixstone, they describe the different stages:

‘1908 saw the introduction of mechanical road transport which was eventually to displace a stable of a score or more of fine draught horses at East Mills. First steam – and then petrol-driven vehicles, which were always maintained in first-class style, rapidly extended the “mill to customer” delivery’ (p.47).

So after steam came petrol-driven vehicles that could transport flour cheaply and had a shorter start up and shut down process than steam powered vehicles did.

Some of the earliest examples came about thanks to the First World War. After the war had ended, ‘there was a massive surplus of lorries and some manufacturers, – Leyland Motors was one, – reconditioned them before releasing them onto the market.’ (Edge, p.24). So motor vehicles started to be used by companies and they continued to develop and improve over time.

Lorries:

Yet again, this mode of transport only lasted for 20 years or so before a more efficient alternative was looked for. Transporting sacks of flour took up lots of space and they were known to split on occasion. Therefore methods of bulk transportation were looked into. The first successful prototype was displayed on 4th August 1950 at Spillers Millennium Mills, London:

‘On view was a Leyland Octopus 22.O/1 eight-wheeler with three cylindrical vertical containers mounted on its chassis…The flour tanks…were made of steel, internally coated with Lithcote for a smooth finish.’ (Edge, p.27)

This prototype was not perfect given issues regarding weight, and it was ultimately Henry Simon Ltd. who solved the problem as they ‘designed a new generation of compact, powerful compressors, (or ‘blowers’ as they became known), able to be driven from a lorry’s gearbox.’ (Edge, p.29). This meant that by the end of the 1950s bulk-flour deliveries had become the favoured method of transport and allowed deliveries to take place in greater quantities whilst being efficient.

Bulk Transport:

So from the humble horse and cart to the steam engine and finally motor engines, the methods to transport flour have gone through many changes over the past century or so, although its importance has not changed. If there was no way to get the product out of the mill or for raw materials to arrive, then a mill would be ruined. Therefore the lorries, steam engines and horses and carts played an important, although often overlooked, role in the milling industry.

Sources:

Edge, Graham, Milled from Golden Fields: A Pictorial History of Flour Millers’ Transport in Great Britain (Cambridge, 2003).